When one of our DTC clients scaled from $50,000 to $5 million in annual sales, their logistics strategy evolved through three distinct phases—each requiring different approaches to Chinese sourcing and fulfillment. As founder of GeeseCargo, I've learned that e-commerce logistics success isn't about finding one perfect solution, but building systems that adapt as you grow. The difference between profitable scaling and logistical nightmares often comes down to mastering a few critical principles.

Successful e-commerce logistics from China requires integrated inventory management, strategic shipping mode selection, customs compliance specialization, and technology-driven visibility. Top performers achieve 4-7 day US delivery from Chinese warehouses while maintaining 98.5%+ order accuracy and keeping logistics costs below 18% of product value through systematic optimization.

E-commerce logistics differs fundamentally from traditional import models, emphasizing speed, flexibility, and direct-to-consumer efficiency over pure cost minimization. The most successful sellers treat their logistics operation as a competitive advantage rather than a necessary expense.

How Should You Structure Inventory and Warehousing Strategy?

Inventory management represents the foundation of e-commerce logistics success. Balancing availability with capital efficiency requires sophisticated approaches tailored to e-commerce velocity patterns.

What's the Optimal Balance Between China and US Inventory?

Strategic safety stock in China protects against supply disruptions while minimizing US inventory costs. Maintain 2-3 weeks of forward inventory in Chinese consolidation warehouses for fast replenishment, while keeping 4-6 weeks of inventory in US fulfillment centers based on sales velocity.

Demand-based inventory allocation places faster-moving SKUs in US warehouses and slower items in China. Analyze your ABC inventory classification—A items (top 20% by sales) belong in US fulfillment centers, while C items can ship directly from China to reduce storage costs.

Seasonal inventory planning builds buffer stock before peak seasons. Increase Chinese inventory 60-90 days before Q4 peak, then transition to leaner inventory models during slower periods to optimize working capital.

How Does Warehouse Network Design Impact Performance?

Multi-location US fulfillment reduces last-mile delivery times and costs. Positioning inventory in East Coast, West Coast, and central fulfillment centers enables 2-3 day ground service to 95% of US consumers versus 5-7 days from single locations.

Chinese consolidation warehouses streamline supplier coordination. Using a single warehouse to receive goods from multiple Chinese factories reduces shipping complexity and enables quality control before international shipment.

Hybrid fulfillment models combine US bulk inventory with China direct shipping for optimal flexibility. Stock fast-moving items in US warehouses while shipping slow-moving or custom products directly from China to balance speed and cost.

What Shipping Strategies Balance Speed and Cost?

E-commerce customers increasingly expect Amazon-like delivery speeds while resisting shipping cost premiums. Strategic mode selection creates competitive delivery experiences without destroying margins.

When Should You Choose Air vs Sea Shipping?

Air freight for high-value, low-weight products preserves margin while meeting delivery expectations. Products with high value density (value per kilogram) can absorb air freight costs while maintaining healthy margins—typically items worth $50+ per kilogram.

Sea freight for bulk shipments of slower-moving or seasonal products reduces per-unit costs. For items with lower value density or predictable demand patterns, sea shipping with US fulfillment provides the most cost-effective approach.

Hybrid air-sea logistics offers intermediate speed at compromised cost. Shipping via ocean to West Coast ports then domestic air fulfillment can provide 12-16 day total transit at 30-40% savings over pure air freight.

How Can You Optimize Last-Mile Delivery Economics?

Carrier diversification based on package characteristics and destinations reduces costs. Use USPS for lightweight packages to residential addresses, UPS/FedEx for heavier items, and regional carriers for specific geographic concentrations.

Zone skipping strategies consolidate packages for bulk transportation to specific regions before local delivery. Shipping full pallets to regional sortation centers then local delivery can reduce costs 15-25% for high-volume destinations.

Delivery density analysis identifies optimal fulfillment center locations based on customer concentration. Positioning inventory closer to your highest-density customer clusters reduces last-mile costs and transit times simultaneously.

How Do You Master E-commerce Customs Compliance?

E-commerce shipments face heightened customs scrutiny due to higher fraud incidence and regulatory complexity. Proactive compliance prevents delays that destroy customer experiences.

What Documentation Practices Prevent Customs Delays?

Accurate product descriptions and valuations are non-negotiable for compliance. Avoid generic descriptions like "gadgets" or "accessories"—use specific, detailed descriptions that match your website product pages and include correct Harmonized System codes.

Proper valuation declaring actual selling price prevents customs disputes. State the true transaction value rather than artificially low values, which trigger inspections and penalties. Include shipping and insurance in the declared value when required.

Consistent documentation across all shipments builds customs credibility. Use standardized templates for commercial invoices, packing lists, and certificates of origin to demonstrate professionalism and reduce inspection frequency.

How Should You Handle Duty Optimization Legally?

De Minimis shipment planning utilizes duty-free thresholds for appropriately sized orders. The US $800 de minimis threshold allows duty-free entry for qualifying shipments, making it advantageous to keep individual orders below this value when possible.

First sale for export valuation may apply for certain business models. When buying from Chinese manufacturers then selling to US customers, explore whether first sale valuation could legally reduce your duty burden—but only with proper legal guidance.

Product classification optimization ensures correct duty rates. Work with customs experts to verify your HS codes are optimized—sometimes products qualify for lower duty rates under alternative classifications that still accurately describe the goods.

What Technology Systems Enable E-commerce Logistics Excellence?

Manual processes cannot scale with e-commerce growth. Integrated technology platforms provide the visibility, automation, and analytics needed for competitive logistics operations.

What Visibility Tools Are Essential for Management?

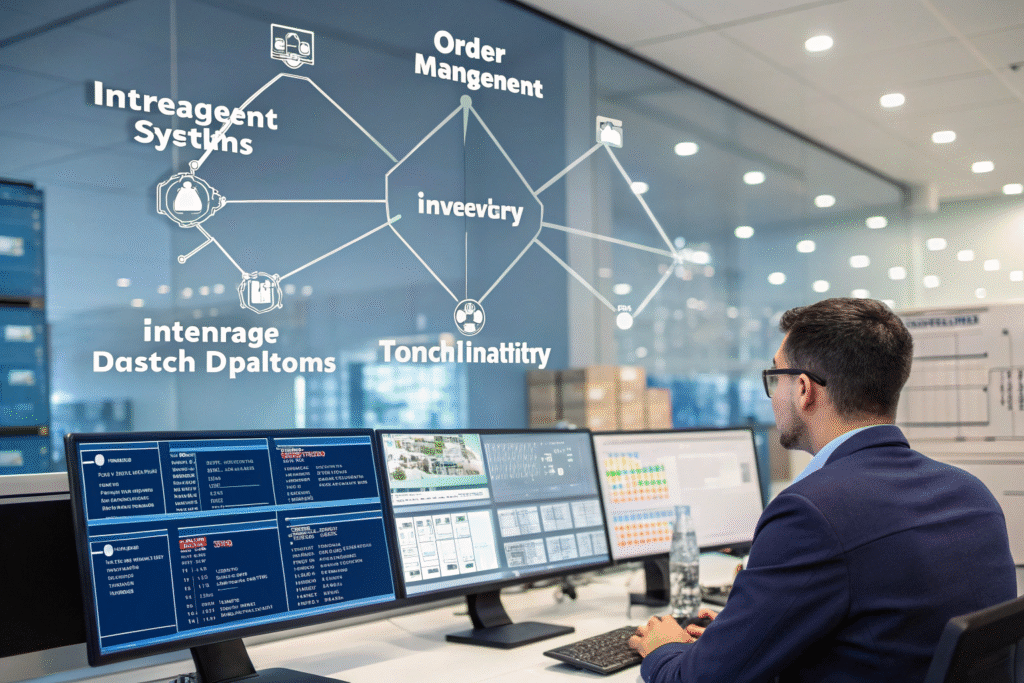

Real-time inventory tracking across all locations prevents stockouts and overstocking. Integrated systems showing Chinese warehouse inventory, in-transit goods, and US fulfillment center levels enable accurate available-to-promise calculations.

Shipment tracking with proactive exception alerts enables customer communication. Provide customers with tracking information and proactively notify them of delays rather than making them contact you with questions.

Performance analytics identify optimization opportunities across the supply chain. Track metrics like order-to-ship time, perfect order percentage, and logistics cost per order to identify improvement priorities.

How Does Automation Improve Operational Efficiency?

Order routing automation selects optimal fulfillment locations based on inventory and delivery requirements. Systems automatically choose whether to fulfill from US inventory or ship directly from China based on cost, speed, and availability.

Shipping documentation generation eliminates manual data entry. Integrated systems automatically create commercial invoices, packing slips, and shipping labels by pulling data from order management platforms.

Customs documentation preparation ensures consistency and accuracy. Automated systems apply business rules to generate compliant customs declarations, reducing errors that cause border delays.

How Can You Build Customer-Centric Returns Management?

E-commerce returns are inevitable, but they don't have to be destructive to profitability. Strategic returns management transforms a cost center into a customer loyalty opportunity.

What Returns Logistics Models Balance Cost and Experience?

US-based returns processing avoids international return shipping costs and complexities. Provide US return addresses even for products shipped from China, then consolidate returns for occasional bulk returns to suppliers or disposition domestically.

Return authorization workflows prevent unnecessary returns and gather valuable data. Simple online forms that require reason codes and photos help reduce return rates while providing product improvement insights.

Intelligent restocking decisions maximize recovered value. Automate decisions about whether to restock, refurbish, liquidate, or destroy returned items based on product value, condition, and restocking costs.

How Should You Handle China-Specific Returns Challenges?

Supplier return agreements establish responsibilities and processes upfront. Negotiate return policies with Chinese suppliers before issues arise, including who bears costs for defective products, who handles inspections, and timeframes for credit issuance.

Quality-controlled return processing in China verifies condition before supplier submission. Use your consolidation warehouse to inspect returns before presenting to factories, ensuring only legitimate quality issues get escalated.

Return shipping consolidation reduces costs through batch processing. Instead of individual return shipments to multiple factories, consolidate returns by supplier and ship periodically to minimize international shipping expenses.

Conclusion

Successful e-commerce logistics from China requires treating your supply chain as an integrated system rather than a series of disconnected activities. The most profitable sellers excel at balancing competing priorities—speed versus cost, inventory investment versus availability, automation versus flexibility.

At GeeseCargo, we've helped hundreds of e-commerce businesses build logistics operations that support scaling from six figures to eight figures and beyond. The journey typically begins with direct China shipping, evolves through US fulfillment center expansion, and matures into sophisticated hybrid models that dynamically optimize for each order's specific requirements.

Begin your logistics optimization by mapping your current processes end-to-end, identifying where delays, costs, or errors occur. Then prioritize improvements based on impact and implementation effort, focusing first on changes that deliver quick wins while building toward more sophisticated capabilities. Remember that in e-commerce logistics, perfection is the enemy of progress—iterative improvement beats delayed perfection every time.