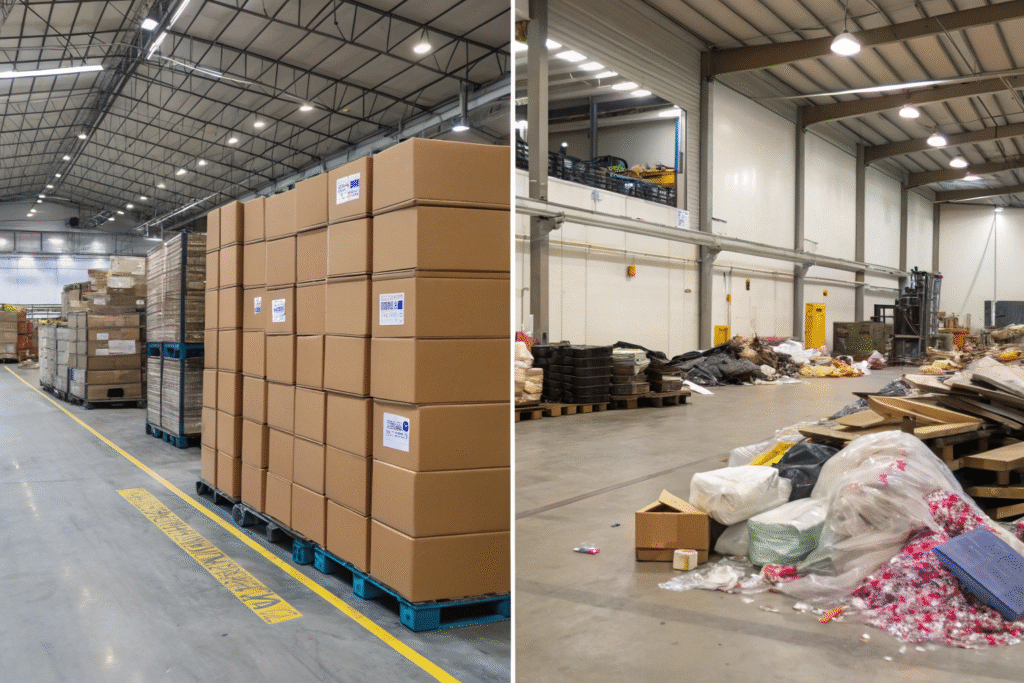

Cargo damage is costly—especially when you're shipping delicate goods from China to the U.S. Like electronics, cosmetics, food-grade gifts, or premium apparel. A drop, a temperature spike, or prolonged humidity can ruin your entire shipment. But now, with the rise of IoT sensors, real-time cargo monitoring is not just possible—it’s affordable and scalable.

IoT cargo sensors allow you to track temperature, shock, tilt, humidity, and location of your shipments from factory to warehouse.

These small, smart devices are placed inside pallets or containers, providing minute-by-minute data during air or ocean transit. Logistics teams can now act instantly when things go wrong—instead of learning about spoilage or impact damage after it’s too late.

Let’s break down how IoT monitoring works, what it can detect, and how we use it at GeeseCargo to protect high-value China-to-USA shipments every day.

How Do IoT Cargo Sensors Work in International Shipping?

![]()

What Technologies Do These Sensors Use?

Modern cargo IoT sensors use cellular, Bluetooth Low Energy (BLE), or satellite connectivity to send data in real-time or near-real-time. Most devices monitor:

- Temperature

- Shock/vibration (in G-force)

- Humidity

- Light (to detect tampering)

- Tilt or orientation

- Location (via GPS or triangulation)

Some advanced sensors also integrate with cloud dashboards to trigger alerts if thresholds are exceeded.

Learn more from top providers like Tive and Sensitech.

Can They Be Used in Ocean & Air Freight?

Yes. Devices must meet airline approval standards (like IATA’s CEIV Pharma) for in-flight use. For ocean freight, they're embedded in containers or attached to pallets inside sealed LCL shipments.

At GeeseCargo, we deploy pre-configured sensors approved for most Asia–U.S. airline partners and major shipping lines like COSCO and CMA CGM.

Check device compliance via IATA’s cargo tech standards and TT Club safety guides.

What Types of Damage Can IoT Sensors Help Prevent?

Can They Catch Temperature Excursions in Transit?

Absolutely. This is one of the most common uses. Perishable or sensitive cargo—like cosmetics, chocolate, skincare products, or leather—can be damaged if temperatures exceed certain limits.

IoT sensors continuously log temperature ranges, and trigger alerts when cold chain conditions are broken. Alerts can be configured to go to mobile apps, emails, or logistics dashboards.

Explore Emerson GO loggers or Controlant temperature systems for pharma-grade tracking.

Can They Detect Shocks or Rough Handling?

Yes. Many modern trackers measure shock in G-force, indicating if a package was dropped, hit, or mishandled. This is crucial for fragile gifts, glassware, or electronics.

For instance, a shock exceeding 20G may indicate a fall from over 1 meter. This data supports damage claims with freight insurance companies or helps identify weak spots in handling protocols.

See how Roambee and Monnit wireless sensors provide multi-condition visibility.

How Is Real-Time Visibility Changing Shipping Behavior?

![]()

Do Teams Really Act on Live Sensor Alerts?

Yes. When alerts are integrated into supply chain control towers or shared logistics platforms, teams can:

- Intercept shipments during customs holds

- Re-ice or reroute cargo with active temperature breach

- Notify carriers about rough handling

- Prioritize unloading of sensitive cargo on arrival

GeeseCargo provides sensor-linked alerts directly to clients’ U.S. receiving teams and Chinese factory staff—cutting response times drastically.

More use cases available at Tive case studies and Project44’s IoT integrations.

How Do Sensors Improve Client Trust and Claims?

Tracking data gives hard proof. If cargo arrives damaged, we can show:

- Exact time and location of incident

- Whether responsibility lies with airline, trucking partner, or terminal

- Historical logs for recurring problems

This builds trust, supports insurance claims, and helps clients optimize packing and routing strategies.

Read real results from Everstream Analytics and Overhaul secure cargo platforms.

How Can You Start Using IoT Tracking for Your China Shipments?

Is It Expensive or Complicated?

Not anymore. GeeseCargo offers IoT tracking options starting at $10–$18 per shipment, depending on duration, conditions tracked, and coverage area.

We provide:

- Disposable or reusable sensors

- Setup and data dashboard access

- Automated reporting

- Alert thresholds tailored to your cargo

Getting started takes just one booking. For long-term clients, we offer fleet-level visibility at no extra charge.

Compare pricing from Tag-N-Trac and Logmore.

What Are the First Steps to Add It?

- Let us know your cargo type and sensitivity

- We’ll recommend a sensor model

- You approve setup costs

- We apply sensors at origin

- You track in real time through our dashboard

Most importantly, we help interpret the data, so you don’t have to hire in-house logistics analysts to benefit from cutting-edge monitoring.

Check GeeseCargo IoT solutions or explore setup guides from DeltaTrak.

Conclusion

IoT cargo sensors are transforming international shipping. From apparel and gifts to electronics and perishables, they offer the power to see, react, and prevent damage before it happens. Real-time temperature, shock, and location monitoring can reduce claims, improve customer trust, and drive smarter decisions. At GeeseCargo, we’ve made this technology easy to access, affordable, and fully integrated with your China-to-U.S. shipping workflows.