When one of our clients faced a $450,000 product recall last year due to non-compliant children's toys, I realized how many importers underestimate US safety requirements. As founder of GeeseCargo with over a decade of China-US shipping experience, I've seen compliance failures destroy businesses overnight. Ensuring your Chinese products meet US standards isn't just about avoiding penalties—it's about building a reputable, sustainable import business.

Chinese products must comply with specific US safety standards enforced by CPSC, FDA, FCC, and other agencies depending on product category. The process involves factory audits, product testing by accredited laboratories, proper documentation, and ongoing compliance monitoring. Most importers should budget 3-8% of product cost for comprehensive compliance assurance.

US safety standards exist to protect consumers, and violations can lead to severe consequences including forced recalls, fines, seizure of goods, and even criminal charges. Understanding the complete compliance pathway prevents costly mistakes and protects your brand reputation.

What Are the Key US Regulatory Agencies and Standards?

Different products fall under various regulatory jurisdictions in the United States. Knowing which agencies govern your products is the foundational step in compliance planning.

Which Products Fall Under CPSC Jurisdiction?

The Consumer Product Safety Commission regulates most consumer goods, with particularly strict requirements for children's products. The Consumer Product Safety Improvement Act (CPSIA) mandates third-party testing and certification for all products designed primarily for children 12 and under.

Children's product requirements include lead content limits (100 ppm), phthalates restrictions, mandatory toy safety standards (ASTM F963), and small parts regulations for young children. The CPSIA also requires tracking labels and durable, permanent product marking.

General use products for adults still face CPSC safety requirements, including general substantial product hazard reporting obligations. Furniture, electronics, clothing, and household items must be free from unreasonable injury risks, though third-party testing may not be mandatory for all adult products.

When Does FDA Regulation Apply to Imported Products?

The Food and Drug Administration regulates food, beverages, dietary supplements, cosmetics, medical devices, drugs, and radiation-emitting electronics. FDA requirements focus on safety, labeling, and manufacturing practices.

Food products require facility registration, prior notice of shipment, and compliance with labeling, additive, and contamination standards. The Food Safety Modernization Act gives FDA enhanced authority to prevent rather than simply respond to food safety issues.

Cosmetics must be safe for consumers under labeled or customary conditions of use, though unlike drugs, they don't require pre-market approval. Cosmetic labeling requirements include ingredient declaration in descending order of predominance.

How Should You Approach Factory Audits and Supplier Verification?

Your compliance journey begins long before production—it starts with selecting qualified suppliers and verifying their capabilities through systematic assessment.

What Should a Compliance-Focused Factory Audit Include?

Quality management system evaluation determines if the factory has structured processes for maintaining consistent quality. Look for ISO 9001 certification or equivalent internal systems, documented procedures, and corrective action processes.

Production process controls ensure manufacturing consistency. Verify that workers follow standardized work instructions, conduct in-process inspections, and maintain equipment properly. Process control failures often cause compliance variations.

Material management systems track component sourcing and prevent unauthorized substitutions. Audit material storage, inventory controls, and supplier qualification processes. Many compliance failures originate from unapproved material changes.

How Can You Verify Supplier Compliance Capabilities?

Request evidence of previous compliance testing for similar products. Reputable suppliers maintain test reports and can demonstrate understanding of US requirements through their documentation and procedures.

Conduct sample testing before full production to identify potential compliance issues. Order pre-production samples and have them tested independently to verify the supplier's capability to meet requirements.

Assess the supplier's testing infrastructure and relationships with accredited laboratories. While most factories use third-party labs, some maintain in-house testing capabilities for basic compliance checks during production.

What Testing and Certification Processes Are Required?

Product testing provides objective evidence of compliance, while certification documents create your legal proof of meeting US safety standards.

How Does Third-Party Testing Work for Regulated Products?

Children's products require testing by CPSC-accepted laboratories for applicable safety rules. The laboratory must be accredited to ISO/IEC 17025 standards and specifically accepted by CPSC for each relevant test method.

Testing must be conducted on samples from production units, not prototypes, to ensure they represent actual products. The CPSC requires sufficient samples to provide a high degree of assurance that the product complies.

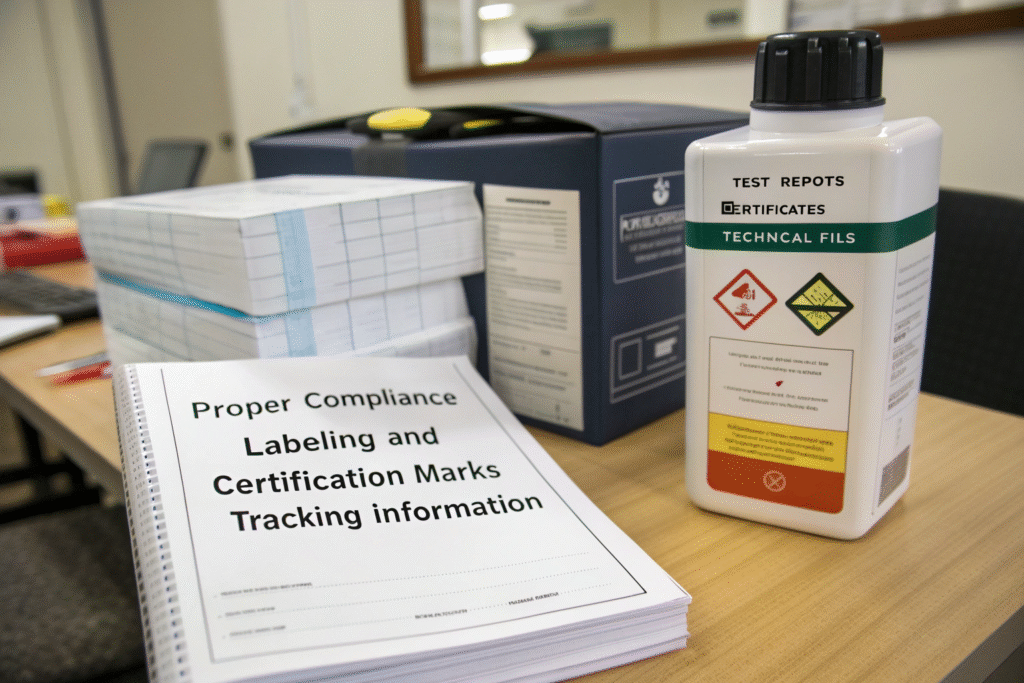

Test reports must be maintained by the importer and provided to CPSC, retailers, and distributors upon request. These reports form the basis for the Children's Product Certificate required for all children's products.

What Documentation Must Accompany Compliant Products?

The Children's Product Certificate is mandatory for products subject to children's product safety rules. This certificate must identify the product, list applicable safety rules, provide manufacturer and importer information, and include contact information for record maintenance.

General Certificate of Conformity is required for non-children's products subject to CPSC safety rules. While less detailed than the Children's Product Certificate, it still provides assurance that the product complies with applicable standards.

Technical files containing test reports, risk assessments, design specifications, and manufacturing details should be maintained for at least five years. These documents prove due diligence if compliance questions arise.

How Should You Handle Labeling and Documentation?

Proper labeling and documentation complete the compliance process, providing consumers with necessary safety information and creating your compliance audit trail.

What Tracking Label Information Is Required?

Children's products must have permanent tracking labels that include source information (manufacturer or private labeler), production date and location, cohort information (batch, run number), and other identifying information.

The tracking label must be permanent and visible to consumers before purchase. While the CPSC doesn't specify exact placement, it must be on the product and its packaging where practical.

General compliance marks like UL, ETL, or FCC identifiers must appear on regulated products. These marks indicate compliance with specific safety or performance standards and help retailers verify compliance status.

How Should You Manage Compliance Documentation?

Create a comprehensive compliance file for each product containing all test reports, certificates, and supporting documentation. This file should be readily accessible for customs, retailers, or regulatory inquiries.

Maintain documentation for a minimum of five years, as this represents the CPSC's statute of limitations for most violations. Electronic records are acceptable if they're complete, legible, and readily available.

Develop a document control system that tracks revision dates, superseded documents, and current compliance status. This system should alert you when testing requires renewal due to standard updates or product changes.

What Ongoing Compliance Monitoring Is Necessary?

Compliance isn't a one-time event—it requires continuous monitoring of both regulatory changes and production consistency to maintain compliance over time.

How Can You Monitor Regulatory Changes?

Subscribe to regulatory agency updates from CPSC, FDA, and other relevant bodies. These agencies publish newsletters, regulatory agendas, and direct notifications about upcoming standard changes.

Join industry associations that provide compliance updates and advocacy. Organizations like the Juvenile Products Manufacturers Association or Toy Association offer specialized compliance resources for their industries.

Work with compliance consultants who monitor regulatory developments globally. Professional compliance services provide early warnings about changes that might affect your products.

What Production Surveillance Should You Implement?

Regular production testing catches compliance drift before it becomes a major issue. Schedule periodic testing of production samples, particularly after material or process changes.

Unannounced factory inspections verify ongoing compliance with manufacturing standards. These inspections help prevent the common pattern of initial compliance followed by gradual erosion of standards.

Material change verification processes require supplier notification and retesting when components or materials change. Many compliance failures occur when suppliers substitute materials without understanding compliance implications.

Conclusion

Ensuring Chinese products meet US safety standards requires a systematic, documented approach spanning supplier selection, production oversight, testing, and ongoing monitoring. The most successful importers treat compliance as an integral business process rather than a last-minute checklist.

At GeeseCargo, we've helped hundreds of clients navigate US compliance requirements, transforming potential liabilities into competitive advantages. The companies that excel in compliance build stronger brands, avoid costly recalls, and develop more reliable supply chains.

Begin your compliance journey by identifying all applicable standards for your products, then work backward through testing, supplier qualification, and documentation requirements. Remember that compliance costs are significantly lower than recall expenses, both financially and reputationally. Investing in comprehensive compliance from the beginning protects your business while building customer trust.