When one of our e-commerce clients analyzed their shipping data and discovered that 32% of their express shipments could have moved via economy service without impacting delivery promises, they unlocked $186,000 in annual savings. As founder of GeeseCargo with a background in data analytics, I've witnessed how data-driven logistics transforms guesswork into precision decision-making. The companies leveraging data effectively aren't just saving money—they're building formidable competitive advantages.

Data-driven logistics decisions can reduce costs by 15-30%, improve delivery reliability by 25-40%, and enhance customer satisfaction by 35-50%. Key data sources include carrier performance metrics, shipping cost analytics, inventory turnover rates, and customer delivery patterns. The most successful companies establish continuous data collection, analysis, and optimization cycles.

Moving from intuitive to data-driven logistics requires building analytical capabilities, but the investment typically returns 3-5x within the first year through optimized operations, reduced errors, and improved resource allocation.

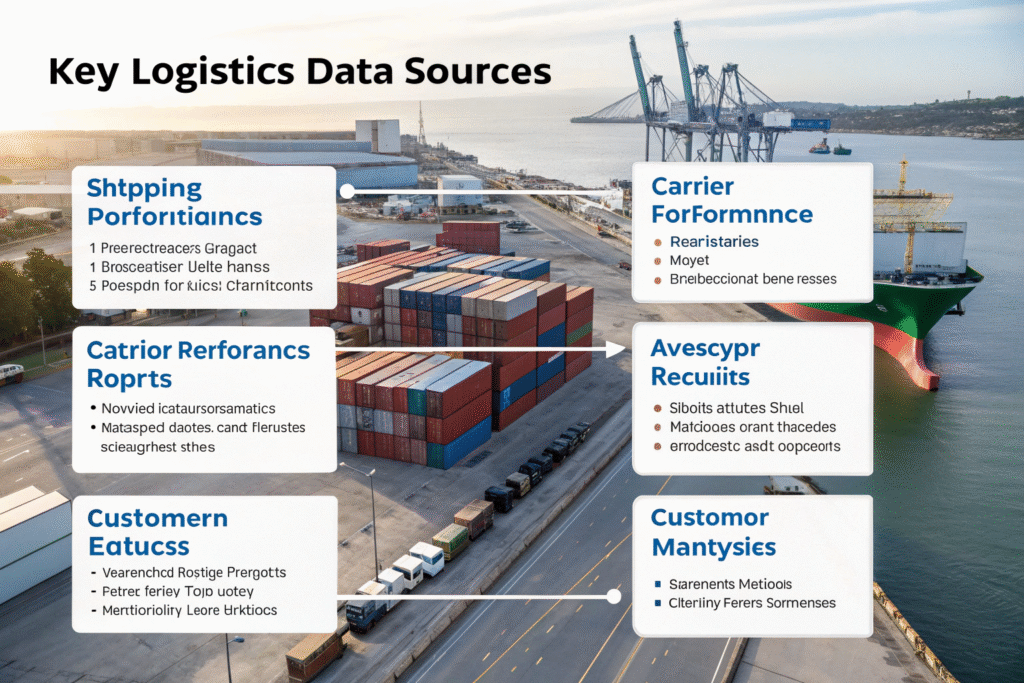

What Logistics Data Should You Collect and Analyze?

Comprehensive data collection forms the foundation for analytical insights, with specific datasets providing unique visibility into different aspects of your supply chain.

Which Operational Data Reveals Cost Optimization Opportunities?

Freight invoice data provides granular cost intelligence. Analyzing line-item charges across carriers, lanes, and service levels reveals pricing inconsistencies, accessorial charge patterns, and opportunities for rate negotiation.

Shipment dimension and weight data identifies packaging inefficiencies. Tracking actual versus billed weight and dimensional weight patterns highlights opportunities to optimize packaging and reduce volumetric charges.

Transit time variability analysis pinpoints reliability issues. Measuring on-time performance standard deviations by lane, carrier, and season enables targeted improvement initiatives where variability causes operational disruptions.

What Customer and Service Data Impacts Business Outcomes?

Delivery experience metrics correlate with customer retention. Analyzing delivery timeliness, condition upon arrival, and communication effectiveness reveals how logistics performance impacts customer loyalty and repeat purchases.

Service level compliance tracking ensures promise alignment. Comparing committed versus actual delivery dates identifies where over-conservative or unrealistic promises create unnecessary costs or service failures.

Return pattern analysis reveals product and process issues. Categorizing returns by reason code, geography, and product type helps identify root causes beyond simple "customer didn't want" explanations.

How Can You Analyze Transportation Data for Cost Reduction?

Transportation typically represents 40-60% of logistics costs, making it the highest-impact area for data-driven optimization.

What Lane and Mode Analysis Lowers Costs?

Lane density analysis identifies consolidation opportunities. Mapping shipment volumes by origin-destination pairs reveals where increased frequency or volume commitments could secure better rates.

Mode selection optimization balances cost and service. Analyzing the cost differential and time impact of air versus ocean, LCL versus FCL, and parcel versus LTL creates data-driven mode selection rules.

Accessorial charge analysis targets avoidable costs. Categorizing and tracking additional charges by type, frequency, and carrier identifies systematic issues rather than one-time anomalies.

How Does Carrier Performance Data Guide Partner Selection?

On-time performance analytics outweigh simple cost comparisons. A carrier charging 15% less but delivering late 20% more often may actually cost more when considering the business impact of delays.

Claim ratio tracking quantifies hidden damage costs. Calculating damage frequency and severity by carrier reveals true total costs beyond published rates.

Capacity commitment analysis ensures partner reliability. Tracking how carriers perform during peak periods versus normal conditions prevents seasonal service surprises.

How Can Inventory Data Optimize Logistics Flows?

Inventory and logistics represent interconnected systems where data-driven alignment creates compound efficiencies and service improvements.

What Demand Pattern Analysis Improves Logistics Planning?

Seasonality analysis enables proactive capacity planning. Identifying predictable demand fluctuations allows forward booking of transportation capacity at favorable rates before peak pricing periods.

Demand volatility measurement informs safety stock strategies. Products with high demand variability may justify premium transportation to lower inventory levels, while stable products benefit from slower, cheaper transport.

Product velocity categorization optimizes distribution strategies. Fast-moving items belong in forward inventory positions, while slow-movers can ship direct from central locations despite longer transit times.

How Does Inventory Turnover Data Impact Transportation Decisions?

Carrying cost versus transportation cost trade-offs become quantifiable. Data models can calculate the optimal balance between inventory investment and transportation expenses based on your specific cost structure.

Lead time variability analysis supports inventory optimization. Understanding transportation reliability patterns enables more accurate safety stock calculations and reorder point settings.

Cross-docking opportunities emerge from order pattern analysis. Identifying frequent customer-product combinations that ship together enables streamlined distribution without storage.

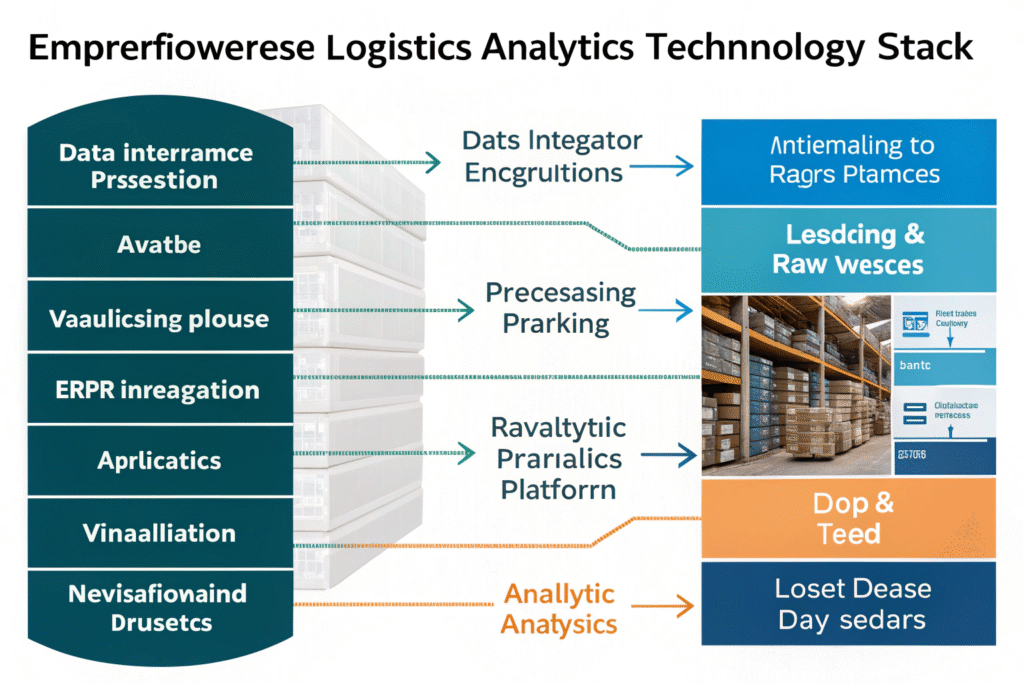

What Technology Enables Data-Driven Logistics?

The right technology stack transforms raw data into actionable insights through automation, visualization, and advanced analytics.

What Data Integration Approaches Work Best?

API connections to carrier systems provide real-time performance data. Direct system integrations eliminate manual data entry and ensure information freshness for critical decision-making.

ERP and WMS integrations create end-to-end visibility. Connecting logistics data with financial, inventory, and order systems provides context for transportation decisions.

IoT and tracking technologies enhance data granularity. Sensor data from containers, vehicles, and warehouses provides unprecedented visibility into shipment conditions and locations.

What Analytical Tools Deliver the Most Value?

Transportation Management Systems with analytics modules provide built-in insights. Modern TMS platforms include reporting, benchmarking, and optimization capabilities specifically designed for logistics data.

Business Intelligence platforms enable custom analysis and visualization. Tools like Tableau, Power BI, or Looker allow creation of tailored dashboards that address your specific business questions.

Machine learning applications identify complex patterns. Advanced algorithms can predict delays, optimize routing, and recommend mode selections based on historical patterns too complex for manual analysis.

How Can You Build a Data-Driven Logistics Culture?

Technology alone cannot create data-driven operations—organizational practices, skills, and processes determine whether data gets used effectively.

What Organizational Practices Embed Data in Decisions?

Regular performance reviews based on data replace anecdotal discussions. Weekly logistics meetings structured around key metrics create accountability and focus improvement efforts.

A/B testing of logistics changes provides evidence for decisions. Trying different approaches with controlled groups generates data about what actually works rather than what should work.

Cross-functional data sharing breaks down operational silos. Sharing logistics data with procurement, sales, and finance enables better collective decision-making.

What Skills Development Supports Analytics Capability?

Data literacy training for logistics staff enables self-service analytics. Teaching basic analytical concepts and tool usage empowers team members to explore data themselves.

Analytical talent acquisition brings specialized skills. Hiring data analysts, scientists, or engineers with logistics experience accelerates capability development.

External expertise engagement fills temporary capability gaps. Consultants, carriers, and technology partners can provide analytical support while building internal capabilities.

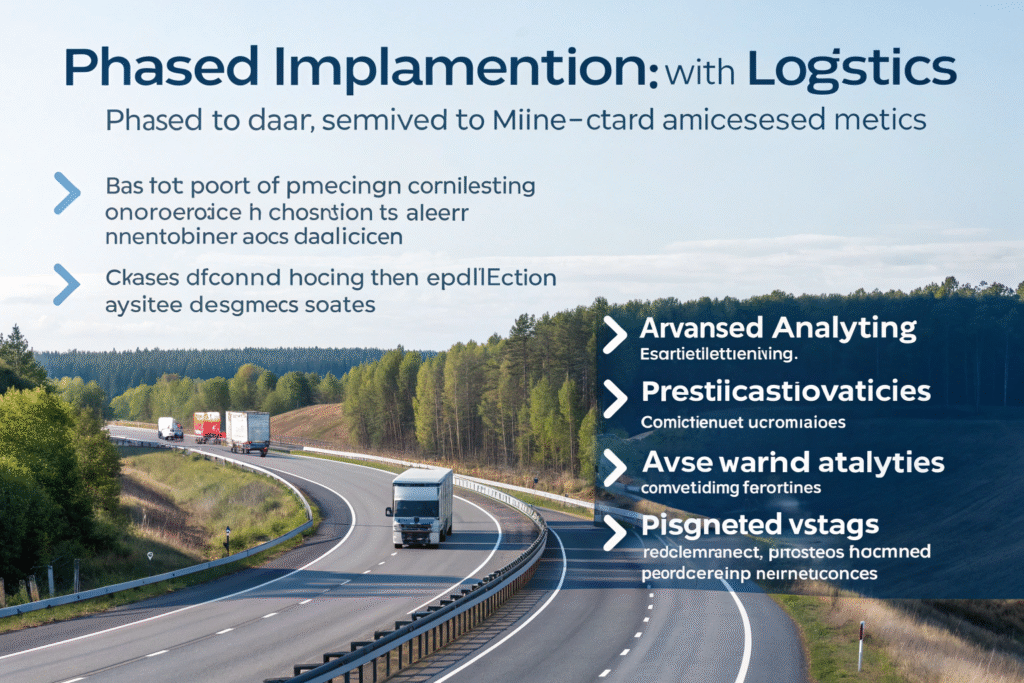

What Are the Implementation Steps for Data-Driven Logistics?

Systematic implementation prevents overwhelming complexity and demonstrates quick wins that build momentum for broader transformation.

Where Should You Start Your Data Journey?

Basic cost and service reporting establishes foundational visibility. Even simple spreadsheets tracking key metrics provide immediate value and identify obvious improvement opportunities.

Carrier performance scorecards create accountability. Starting with basic on-time, cost, and damage metrics for your transportation partners delivers quick improvements.

Process mining identifies workflow inefficiencies. Mapping actual versus planned processes using system data reveals bottlenecks and unnecessary steps.

How Do You Scale from Basic to Advanced Analytics?

Predictive modeling anticipates future requirements. Moving from describing what happened to predicting what will happen enables proactive rather than reactive management.

Prescriptive analytics recommends optimal actions. Advanced systems can suggest specific decisions like carrier selection, routing, or inventory positioning based on optimization algorithms.

Closed-loop optimization creates self-improving systems. Systems that automatically implement decisions, measure results, and adjust approaches create continuous improvement cycles.

Conclusion

Data-driven logistics represents the single most significant opportunity for competitive advantage in modern supply chain management. The most successful companies treat data as a strategic asset, building capabilities that transform information into improved decisions, reduced costs, and enhanced customer experiences.

At GeeseCargo, we've helped clients achieve an average of 23% logistics cost reduction through systematic data analysis, with the best results coming from companies that approach data as a continuous improvement journey rather than a one-time project. The key is starting with clear business questions, building foundational capabilities, and progressively advancing analytical sophistication.

Begin your data journey by identifying your most pressing logistics challenges, then collecting the data needed to understand and address them. Remember that perfect data is the enemy of good decisions—starting with available data and improving quality over time beats waiting for perfect information while competitors advance.