When one of our clients had a $45,000 shipment rejected at Australian customs due to missing ISPM 15 stamps, the resulting delays and treatment costs erased their entire profit margin. As founder of GeeseCargo with over a decade of international shipping experience, I've learned that ISPM 15 compliance isn't optional—it's a mandatory requirement that protects global ecosystems while ensuring your shipments clear customs smoothly.

ISPM 15 stamp is required on most solid wood packaging materials (over 6mm thick) used in international trade, including pallets, crates, and dunnage. The certification confirms the wood has been heat-treated or fumigated to eliminate pests. Non-compliant shipments face rejection, forced treatment, or destruction at the importer's expense in over 180 participating countries.

The International Standards for Phytosanitary Measures No. 15 represents a global effort to prevent transnational transport of pests and diseases through wood packaging materials. Understanding its requirements is essential for any business using wood in their international shipments.

What Exactly Does ISPM 15 Regulate?

ISPM 15 specifically targets wood packaging material that could harbor tree pests, establishing standardized treatment requirements and a certification system recognized globally.

Which Wood Packaging Materials Require ISPM 15 Compliance?

Solid wood packaging materials over 6mm thickness fall under ISPM 15 regulation. This includes pallets, crates, boxes, drums, and load boards that are typically raw wood rather than processed wood products.

Dunnage and bracing materials used to secure cargo must comply. Wood blocks, wedges, and spacers placed between cargo items to prevent shifting during transit require the same treatment as structural packaging.

Repaired or remanufactured wood packaging needs retreatment and recertification. Any wood packaging that has been significantly repaired or taken apart and reassembled loses its certification and requires renewed ISPM 15 compliance.

What Wood Materials Are Exempt from ISPM 15?

Processed wood products created using glue, heat, and pressure are exempt. These include plywood, oriented strand board, particle board, and veneer that undergo manufacturing processes that eliminate pest risks.

Wood pieces less than 6mm thick in any dimension are excluded. Thin wood materials don't provide sufficient habitat for wood-boring pests to establish themselves.

Sawdust, wood wool, and shavings are exempt from requirements. These materials don't contain the bark or structural integrity needed to harbor regulated pests.

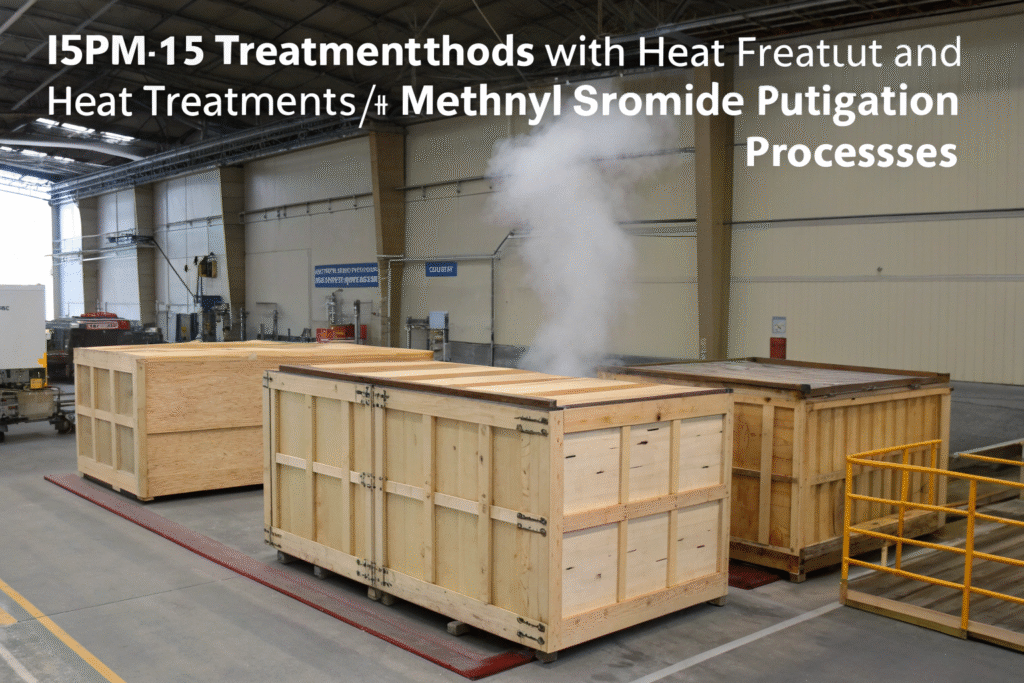

What Are the Approved Treatment Methods?

ISPM 15 recognizes two primary treatment methods that effectively eliminate pests while preserving the wood's structural integrity for packaging use.

How Does Heat Treatment Work?

Core temperature must reach 56°C for minimum 30 minutes throughout the wood. This is typically achieved in specialized chambers using steam, dry heat, or microwave technologies that penetrate the entire wood mass.

Monitoring and documentation requirements ensure treatment verification. Treatment facilities must maintain detailed records including time, temperature, and batch information for audit purposes.

No residual chemicals remain in the wood after treatment. Heat treatment is considered environmentally preferable since it leaves no chemical residues that could leach into products or the environment.

When Is Methyl Bromide Fumigation Used?

Fumigation serves as an alternative when heat treatment isn't feasible. Some wood types or packaging configurations may not accommodate heat treatment, making fumigation the only compliant option.

Strict application protocols ensure effectiveness and safety. Fumigation must occur in enclosed spaces with precise concentration monitoring for specified exposure periods under professional supervision.

Environmental concerns are leading to reduced fumigation use. Many countries are restricting methyl bromide due to ozone depletion concerns, making heat treatment the preferred method in most regions.

How Is Compliance Verified and Documented?

The ISPM 15 stamp provides visible certification, but proper documentation and verification processes ensure compliance throughout the supply chain.

What Information Must the ISPM 15 Stamp Include?

IPPC symbol (International Plant Protection Convention) must appear clearly. The distinctive IPPC logo identifies compliant wood packaging to customs officials worldwide.

Country code and treatment provider number provide traceability. The unique identification allows customs to verify the treatment facility's credentials and compliance history.

Treatment method code indicates how the wood was processed. "HT" signifies heat treatment, "MB" indicates methyl bromide fumigation, and "KD" represents kiln-drying (which also meets heat treatment standards).

What Documentation Supports the Physical Stamp?

Treatment certificates should be maintained for audit purposes. While the stamp is the primary compliance indicator, treatment facilities should provide certificates detailing treatment dates, methods, and batches.

Supplier compliance verification ensures ongoing compliance. Regular audits of wood packaging suppliers help maintain compliance and prevent introduction of non-compliant materials into your supply chain.

Internal tracking systems help manage compliance across shipments. Maintaining records of which shipments used compliant packaging simplifies problem resolution if questions arise.

What Are the Consequences of Non-Compliance?

The risks of non-compliance extend beyond simple delays to include significant financial penalties, operational disruptions, and reputational damage.

What Immediate Operational Impacts Occur?

Customs rejection and shipment holds happen immediately upon discovery. Non-compliant shipments are typically stopped at the first port of entry, regardless of final destination.

Forced treatment at importer's expense creates unexpected costs. Shipments may be required to undergo treatment at approved facilities, with costs often 2-3 times normal treatment rates due to emergency scheduling.

Destruction orders may be issued for severely infested wood. When live pests are detected, the entire wood packaging may be ordered destroyed, potentially damaging the products it contains.

What Financial Penalties and Additional Costs Accumulate?

Demurrage and storage charges accrue during compliance resolution. While shipments are held for treatment or inspection, daily charges quickly accumulate, often exceeding the product value for extended delays.

Treatment costs for non-compliant shipments typically range from $200-$800 per container. Emergency treatment services command premium pricing, particularly when requiring specialized equipment or facilities.

Product damage during retreatment or handling creates additional losses. The process of unloading, treating, and reloading shipments increases handling that can damage products.

How Can You Ensure Ongoing Compliance?

Maintaining consistent ISPM 15 compliance requires systematic approaches to supplier management, internal processes, and documentation practices.

What Supplier Management Practices Ensure Compliance?

Approved supplier programs for wood packaging providers. Vetting and certifying suppliers based on their ISPM 15 compliance track record prevents introduction of non-compliant materials.

Regular audits of treatment facilities and processes. On-site verification that suppliers maintain proper treatment records and stamping procedures ensures ongoing compliance.

Certificate requirements for each wood packaging shipment. Requiring suppliers to provide treatment certificates with each delivery creates a paper trail for compliance verification.

What Internal Controls Prevent Compliance Lapses?

Incoming inspection of all wood packaging materials. Visual verification of ISPM 15 stamps upon receipt catches non-compliant materials before they enter production or shipping processes.

Staff training on identification of compliant packaging. Educating warehouse and shipping personnel to recognize proper stamps prevents accidental use of non-compliant materials.

Documentation retention for all international shipments. Maintaining treatment certificates and supplier documentation for 2-3 years provides evidence of due diligence if questions arise.

What Special Considerations Apply to Different Countries?

While ISPM 15 is an international standard, individual countries may implement additional requirements or enforcement variations.

Which Countries Have Strictest Enforcement?

United States through USDA APHIS actively enforces ISPM 15. The US conducts random inspections and may assess penalties for repeated non-compliance, particularly for wood packaging from high-risk regions.

Australia and New Zealand have particularly stringent requirements. These countries have unique ecosystems highly vulnerable to introduced pests, leading to rigorous inspection regimes and low tolerance for violations.

European Union member states enforce through their national plant protection organizations. While coordinated at EU level, enforcement intensity varies by country, with northern European nations typically most rigorous.

Are There Regional Variations in Requirements?

Bark tolerance levels vary between countries. Some countries permit minimal bark remnants while others require complete bark removal, creating different inspection standards.

Additional declarations sometimes accompany specific commodities. Certain agricultural products or shipments from pest-prevalent regions may require supplemental phytosanitary certificates.

Treatment method preferences differ by region. Some countries strongly prefer heat treatment over fumigation due to environmental concerns, potentially affecting acceptance of certain treatment methods.

Conclusion

ISPM 15 compliance is non-negotiable for international shipments using wood packaging. The modest investment in compliant packaging pales in comparison to the costs and disruptions of non-compliance, which can include refused shipments, mandatory treatments, and significant financial penalties.

At GeeseCargo, we've helped hundreds of clients implement ISPM 15 compliance programs that eliminate customs delays while protecting global ecosystems. The most successful approaches treat compliance as an integrated supply chain requirement rather than a last-minute checklist item, building robust processes that ensure every shipment meets international standards.

Begin your compliance journey by auditing your current wood packaging sources and implementing systematic verification processes. Remember that in international shipping, prevention is infinitely more cost-effective than correction when it comes to phytosanitary regulations. Proper ISPM 15 compliance isn't just about avoiding penalties—it's about ensuring your shipments reach their destination without unnecessary delays or complications.