When one of our retail clients used predictive analytics to anticipate port congestion, they rerouted shipments and avoided $2.3 million in potential lost sales during the peak season. As founder of GeeseCargo with extensive data analytics experience, I've witnessed how big data transforms supply chain management from reactive firefighting to proactive issue prevention. The question is no longer whether big data can help—it's how quickly you can implement these capabilities before competitors leave you behind.

Big data can predict 70-85% of supply chain issues days or weeks in advance by analyzing patterns across weather, geopolitical events, carrier performance, and historical disruption data. Companies using predictive analytics typically reduce supply chain disruptions by 40-60%, decrease inventory buffers by 15-25%, and improve on-time delivery by 25-35% through proactive interventions.

The most successful companies treat supply chain analytics as a competitive advantage rather than just an operational tool. By leveraging diverse data sources and machine learning algorithms, they identify patterns invisible to human analysis and prevent issues before they impact customers or costs.

What Types of Supply Chain Issues Can Big Data Predict?

Predictive analytics can forecast various supply chain disruptions with different levels of accuracy and lead time.

How Accurately Can Transportation Delays Be Predicted?

Port congestion can be predicted 7-14 days in advance with 75-85% accuracy. By analyzing vessel schedules, weather patterns, labor negotiations, and historical congestion data, algorithms can forecast bottlenecks before they impact your shipments.

Carrier performance issues can be anticipated 30-60 days ahead with 70-80% accuracy. Machine learning models analyzing on-time performance, equipment availability, and financial indicators can identify carriers likely to deteriorate before service failures occur.

Weather-related disruptions can be forecasted 3-10 days ahead with 85-90% accuracy. Advanced weather modeling combined with route-specific vulnerability analysis predicts storms, floods, or other natural events that could delay shipments.

What Inventory and Demand Issues Are Predictable?

Stockouts can be predicted 2-4 weeks in advance with 80-90% accuracy. By analyzing sales trends, promotion calendars, supplier lead times, and inventory velocity, systems can flag potential shortages before they impact customer service.

Excess inventory can be identified 1-2 months before it becomes problematic. Predictive models analyzing demand patterns, product lifecycles, and market trends can highlight slow-moving inventory before it requires costly markdowns or storage.

Supplier reliability issues can be detected 45-60 days before they cause production delays. Financial data, performance history, and external risk factors can identify suppliers likely to experience quality or delivery problems.

What Data Sources Power These Predictions?

The predictive power comes from combining diverse data streams that collectively reveal patterns no single source can show.

What Internal Data Sources Provide the Foundation?

Historical performance data creates baseline patterns and trends. Order histories, carrier performance records, inventory turns, and supplier reliability data establish normal patterns and identify deviations.

Real-time operational data enables current state assessment. WMS, TMS, and ERP systems provide continuous updates on inventory levels, order status, and shipment locations for immediate analysis.

IoT sensor data offers unprecedented granularity. Container sensors, warehouse monitors, and vehicle telematics provide real-time condition data that predicts maintenance issues or environmental impacts.

What External Data Sources Enhance Prediction Accuracy?

Weather and climate data predict natural disruptions. Historical weather patterns, real-time forecasts, and climate models help anticipate storms, floods, or other weather-related supply chain impacts.

Geopolitical and economic indicators forecast macro disruptions. Trade policy changes, economic sanctions, labor negotiations, and political instability data help predict broader supply chain disruptions.

Market and social sentiment analysis anticipates demand shifts. Social media trends, news analysis, and market intelligence help predict demand fluctuations that could strain supply chains.

How Do You Implement Predictive Analytics Practically?

Successful implementation requires a phased approach that delivers quick wins while building toward more sophisticated capabilities.

What Are the Foundational Steps for Getting Started?

Data assessment and consolidation creates the necessary foundation. Identifying available data sources, assessing data quality, and establishing data governance enables effective analytics.

Initial use case selection focuses on high-impact, achievable projects. Starting with specific, valuable predictions like carrier delay forecasting or inventory optimization demonstrates value quickly.

Technology infrastructure selection balances capability and complexity. Choosing between built-in ERP analytics, specialized supply chain platforms, or custom solutions depends on existing systems and analytical maturity.

How Can You Scale from Initial to Advanced Capabilities?

Progressive complexity expansion builds on early successes. Starting with simpler statistical models and progressing to machine learning as data quality and organizational readiness improve.

Cross-functional integration expands impact beyond logistics. Connecting supply chain predictions with procurement, manufacturing, and sales creates enterprise-wide benefits.

Continuous improvement cycles refine prediction accuracy. Regularly reviewing prediction accuracy, analyzing false positives/negatives, and incorporating new data sources steadily improves performance.

What Are the Most Valuable Predictive Use Cases?

Some applications deliver disproportionate value, making them ideal starting points for predictive initiatives.

How Does Predictive Demand Forecasting Create Value?

Inventory optimization reduces carrying costs while improving service levels. Companies using predictive demand forecasting typically reduce inventory levels by 15-25% while improving fill rates by 5-15%.

Production planning efficiency improves resource utilization. Accurate demand predictions enable better capacity planning, raw material procurement, and production scheduling.

Transportation planning benefits from volume anticipation. Knowing future shipment volumes in advance allows better carrier negotiations, equipment positioning, and route planning.

What Value Comes from Transportation Delay Prediction?

Proactive rerouting avoids disruptions and additional costs. Predicting delays 7-10 days in advance enables shipment rerouting that maintains delivery schedules despite intermediate disruptions.

Buffer inventory optimization reduces safety stock requirements. Knowing which lanes and times face highest delay risks allows targeted safety stock rather than blanket inventory buffers.

Customer communication improvements enhance satisfaction. Advance notice of potential delays enables proactive customer communication and expectation management.

What Implementation Challenges Should You Anticipate?

Despite the potential benefits, predictive analytics face significant implementation hurdles that require careful management.

What Technical and Data Challenges Are Most Common?

Data quality and integration problems undermine prediction accuracy. Incomplete, inconsistent, or inaccurate data creates misleading predictions that damage credibility and decision quality.

Legacy system limitations restrict data access and processing. Older ERP, WMS, and TMS systems may not provide the data accessibility or processing capabilities needed for effective analytics.

Skill gaps in data science and analytics hinder implementation. Shortages of professionals who understand both analytics and supply chain operations can slow progress and reduce effectiveness.

What Organizational and Cultural Hurdles Exist?

Resistance to data-driven decision making protects existing processes. Employees accustomed to experiential decision-making may distrust algorithmic recommendations, particularly early when accuracy is still improving.

Unrealistic expectations about prediction accuracy cause disillusionment. Expecting perfect predictions rather than probabilistic guidance leads to disappointment when some predictions prove incorrect.

Cross-functional collaboration requirements create coordination challenges. Effective prediction requires integration across procurement, logistics, manufacturing, and sales, which often operate in silos.

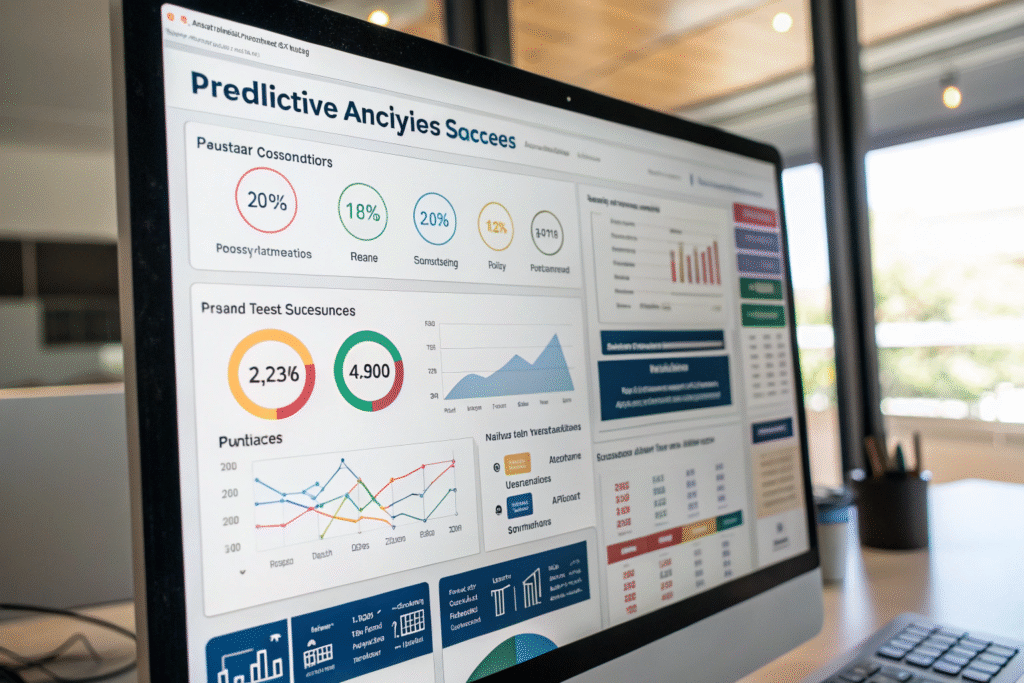

How Do You Measure Predictive Analytics Success?

Clear metrics and regular assessment ensure predictive initiatives deliver tangible business value.

What Technical Metrics Assess Prediction Quality?

Prediction accuracy measures how often forecasts prove correct. Tracking the percentage of accurate predictions across different issue types and time horizons helps refine models and set realistic expectations.

False positive and negative rates balance risk and opportunity. Understanding how often the system predicts problems that don't materialize versus missing actual problems helps optimize alert thresholds.

Lead time accuracy assesses prediction usefulness. Measuring how far in advance predictions occur and whether that provides sufficient time for effective intervention determines practical value.

What Business Metrics Demonstrate Operational Impact?

Disruption reduction quantifies problem prevention. Tracking the frequency and severity of supply chain issues before and after implementation shows preventive effectiveness.

Cost savings measure financial benefits. Reduced expediting, lower inventory, fewer stockouts, and decreased waste should generate measurable cost improvements.

Service level improvements show customer impact. On-time delivery, order accuracy, and customer satisfaction metrics should improve as predictions enable better planning and execution.

Conclusion

Big data can not only predict supply chain issues but fundamentally transform how companies manage their operations from reactive problem-solving to proactive opportunity capture. The most successful implementations start with clear business objectives, build gradually from proven use cases, and focus on organizational adoption as much as technical capability.

At GeeseCargo, we've helped clients achieve an average of 47% reduction in supply chain disruptions through predictive analytics, with the best results coming from companies that treat data as a strategic asset rather than just an operational tool. The key is recognizing that prediction is a journey rather than a destination—each successful prediction builds credibility and capability for more ambitious applications.

Begin your predictive journey by identifying your most costly or frequent supply chain issues, then assess available data sources, and start with focused pilots that deliver quick wins. Remember that in predictive analytics, perfection is the enemy of progress—starting with imperfect predictions that provide some advance warning is dramatically more valuable than waiting for perfect models that never arrive.