As global trade volumes continue to grow and supply chain expectations accelerate, port technology represents one of the most promising areas for reducing shipping times and improving reliability. Many importers wonder if these technological advancements will translate to tangible improvements in their shipment timelines or remain theoretical improvements that don't impact actual transit times.

New port technology will significantly speed up your shipments by reducing vessel waiting times, accelerating cargo handling, streamlining documentation processes, and minimizing human errors. Major technological implementations typically reduce total port time by 30-50%, potentially saving 2-5 days on typical China-US shipping routes through combined efficiency improvements.

Let's examine the specific technologies delivering these time savings, their implementation timelines, and how different types of shipments will benefit from these advancements.

How will automation reduce vessel and cargo handling times?

Port automation represents the most visible technological advancement, with automated cranes, guided vehicles, and smart yard management transforming traditional labor-intensive operations. These systems operate continuously with precision that significantly outpaces manual operations.

Automated container terminals can achieve 25-40 moves per hour compared to 15-25 with conventional equipment, reducing vessel port time by 30-60%. Automated stacking cranes with optimized algorithms reduce container retrieval times from hours to minutes. Autonomous guided vehicles transport containers between vessel and yard with 99.9% accuracy versus human-operated equipment. Smart yard management systems optimize container placement based on departure schedules, minimizing repositioning needs. These combined automation technologies typically reduce total port time by 1-3 days depending on terminal size and vessel size.

What specific automation technologies deliver the biggest time savings?

High-impact automation implementations:

- Automated stacking cranes that operate 24/7 without shifts changes or breaks

- Autonomous guided vehicles that optimize transport routes in real-time

- Automated gate systems that process trucks in 2-3 minutes instead of 20-30 minutes

- Robotic inspection systems that scan containers without slowing operations

- Predictive positioning algorithms that pre-position containers based on vessel schedules

These technologies collectively transform port operations from sequential to parallel processing.

How quickly are major ports implementing automation?

Automation implementation timeline:

- Tier 1 Chinese ports (Shanghai, Ningbo, Shenzhen): 60-80% automated by 2025

- US West Coast ports (LA/Long Beach, Seattle): 40-60% automated by 2026

- European hub ports (Rotterdam, Hamburg): 50-70% automated by 2025

- Emerging Asian hubs (Singapore, Busan): 70-85% automated by 2025

- Secondary ports: Gradual automation focusing on specific high-impact areas

This phased implementation means benefits will accumulate progressively rather than simultaneously.

How will digital documentation and data exchange accelerate processes?

The documentation and data exchange components of shipping have traditionally created significant delays, with paper-based processes and manual verification consuming days in the shipment timeline. Digital transformation addresses these inefficiencies directly.

Blockchain-based documentation systems enable instant, secure document transfer and verification. API integrations allow real-time data exchange between carriers, terminals, and customs authorities. Digital twins create virtual port models that optimize operations before physical activities begin. Electronic bills of lading eliminate courier delays for original documents. These digital advancements typically reduce documentation-related delays by 2-4 days and eliminate the "document race" where cargo arrives before paperwork.

What specific digital systems reduce documentation delays?

Key digital advancements:

- Electronic bills of lading eliminating 3-7 day courier delays

- Blockchain documentation providing instant verification and transfer

- API integration platforms enabling real-time status updates

- Digital customs platforms allowing pre-arrival processing

- Smart contracts automating document compliance checking

These systems transform documentation from a sequential process to simultaneous verification.

How do digital systems improve coordination between parties?

Coordination enhancements include:

- Real-time visibility for all stakeholders into document status

- Automated exception alerts when documents require attention

- Integrated communication platforms reducing email chains and confusion

- Centralized document repositories accessible to authorized parties

- Automated compliance checking before submission to authorities

Improved coordination prevents the miscommunications that traditionally caused documentation delays.

How will IoT and real-time tracking improve port efficiency?

Internet of Things technology provides unprecedented visibility into equipment status, container locations, and operational bottlenecks. This real-time data enables proactive management rather than reactive problem-solving.

Smart containers with IoT sensors transmit location, temperature, and security status continuously. Equipment sensors monitor crane performance and predict maintenance needs before failures occur. Terminal traffic management systems optimize truck movement based on real-time congestion data. Berth allocation systems use predictive analytics to minimize vessel waiting times. These IoT applications typically reduce unplanned delays by 40-60% and improve equipment utilization by 25-35%.

What specific IoT applications deliver operational improvements?

High-value IoT implementations:

- Equipment monitoring sensors predicting maintenance needs before failures

- Container tracking devices providing real-time location and condition data

- Traffic flow sensors optimizing truck movement through terminals

- Environmental monitors adjusting operations based on weather conditions

- Security sensors detecting anomalies without slowing operations

These applications transform port management from reactive to predictive.

How does real-time data improve decision-making?

Data-enhanced decisions include:

- Dynamic berth allocation based on actual vessel arrival times

- Equipment deployment optimized for current operational needs

- Labor allocation matching workforce to actual workload requirements

- Maintenance scheduling during natural operational lulls

- Resource prepositioning based on predictive arrival patterns

Better decisions based on real-time data prevent cascading delays throughout operations.

How will artificial intelligence optimize port operations?

Artificial intelligence applications process massive datasets to identify optimization opportunities that escape human analysis. These systems continuously learn and improve, creating ever-more-efficient operations.

AI-powered predictive analytics forecast vessel arrival times with 95% accuracy 7 days in advance. Machine learning algorithms optimize yard planning based on thousands of variables. Computer vision systems inspect containers and identify damage without slowing operations. Natural language processing automates document verification and exception identification. These AI applications typically reduce operational variability by 30-50% and improve resource utilization by 20-40%.

What AI applications have the most immediate impact?

High-impact AI implementations:

- Predictive arrival systems reducing vessel waiting times

- Intelligent yard management optimizing container positioning

- Automated damage detection identifying issues during normal operations

- Demand forecasting anticipating volume spikes and preparing resources

- Route optimization for internal terminal vehicle movement

These applications deliver measurable efficiency improvements within months of implementation.

How does machine learning continuously improve operations?

Continuous improvement mechanisms:

- Pattern recognition identifying previously unnoticed inefficiencies

- Predictive modeling anticipating problems before they occur

- Optimization algorithms testing thousands of operational scenarios

- Anomaly detection flagging unusual patterns for investigation

- Performance feedback loops incorporating outcomes into future decisions

This learning capability means AI systems become more valuable over time.

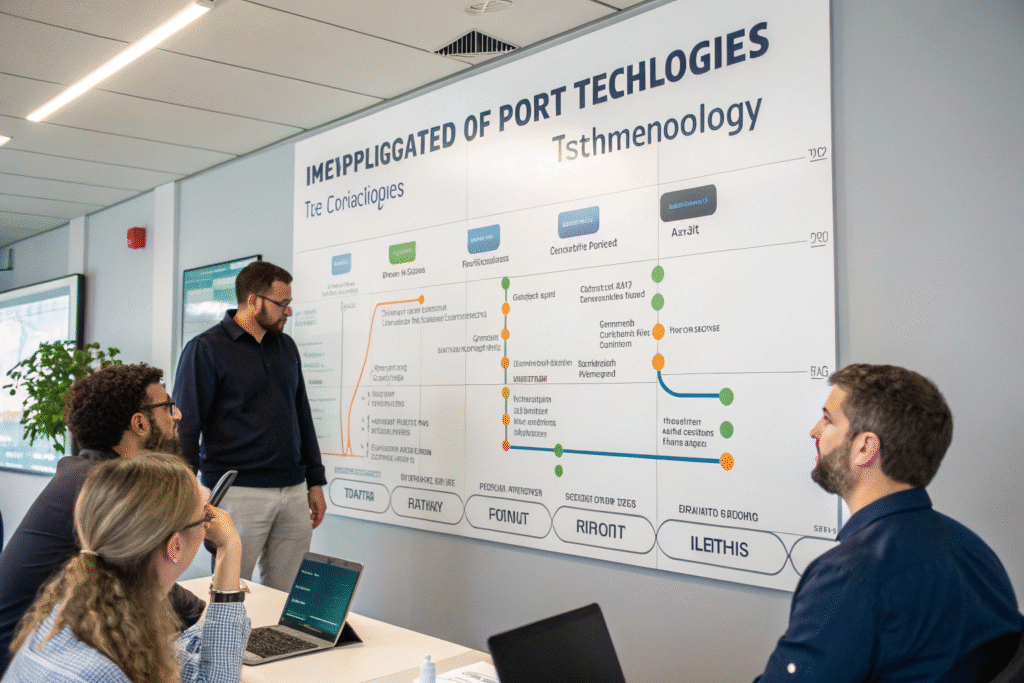

What is the realistic timeline for widespread implementation?

While individual technologies demonstrate impressive benefits, their collective impact depends on widespread implementation across global port networks. Understanding the realistic adoption timeline helps set proper expectations for when these benefits will materially affect your shipments.

Major hub ports will achieve comprehensive technological integration by 2025-2027, with secondary ports following by 2028-2030. The most significant time savings will initially benefit large-volume carriers and frequent importers, with trickle-down effects reaching smaller shippers by 2026-2028. Documentation digitization will advance most rapidly, with physical automation progressing more gradually due to infrastructure investment requirements. The combined effect will be progressively faster transit times rather than sudden dramatic improvements.

Which technologies will deploy most rapidly?

Fast-implementation technologies:

- Digital documentation systems (2024-2026 for major trade lanes)

- API integration platforms (2024-2027 for partner ecosystems)

- IoT tracking devices (2025-2028 for comprehensive coverage)

- AI optimization software (2024-2027 for decision support)

- Automated gate systems (2025-2028 for high-volume ports)

These software-based technologies deploy faster than physical infrastructure changes.

How will implementation vary by port and region?

Implementation variations:

- Asian hub ports leading in physical automation and robotics

- European ports excelling in data integration and green technologies

- US ports progressing steadily with mixed public-private investment

- Middle Eastern ports implementing comprehensive new-built automation

- African and South American ports focusing on specific high-impact technologies

Understanding these regional patterns helps anticipate which trade lanes will improve first.

Conclusion

New port technology will significantly speed up your shipments through combined improvements in physical operations, documentation processing, data exchange, and predictive optimization. The most substantial benefits will emerge between 2025-2030 as technologies reach critical mass across global port networks. While the improvements will be progressive rather than instantaneous, forward-looking shippers can already position themselves to benefit by working with technologically advanced carriers, implementing digital documentation practices, and maintaining flexible supply chain strategies. The companies that understand and adapt to these technological shifts will gain competitive advantages through faster, more reliable shipping while their competitors still operate with outdated expectations about port delays and documentation timelines.