In freight forwarding, time lost is money lost. A single delay can disrupt entire operations.

Timeliness is crucial in freight forwarding because late shipments can hurt supply chains, increase costs, and damage customer relationships. Freight forwarders like GeeseCargo play a key role in keeping cargo on schedule across borders.

In my experience, what matters most to importers isn’t just the price—it’s when the goods arrive. Let’s look at why timeliness is the true foundation of effective freight forwarding.

How delays impact supply chain and inventory levels

When cargo doesn’t arrive on time, it throws off everything from warehouse operations to sales forecasts.

Freight delays disrupt supply chains by creating inventory shortages, warehouse overflows, and missed sales windows. This reduces operational efficiency and customer satisfaction.

What kinds of delays affect importers?

- Port congestion: Slows unloading and customs

- Carrier rollovers: Missed bookings and late vessels

- Truck availability issues: Last-mile bottlenecks

- Document problems: Customs clearance holdups

One client of ours in the U.S. ran out of gift packaging materials during peak season because a shipment was held 4 days in China over an HS code error. It cost them shelf space in major stores.

| Delay Source | Resulting Problem |

|---|---|

| Late container arrival | Empty shelves or paused production |

| Missed clearance window | Higher storage and demurrage charges |

| Poor tracking visibility | No way to prepare warehouse in time |

| Delay during transfer | Missed promotions or campaign launches |

How does this affect inventory control?

Late cargo means:

- Rush restocking costs

- Air freight upgrades to catch up

- Overstock from previous reorders

- Lost sales opportunities

At GeeseCargo, we track each milestone to flag issues early—helping clients avoid running out or overloading inventory.

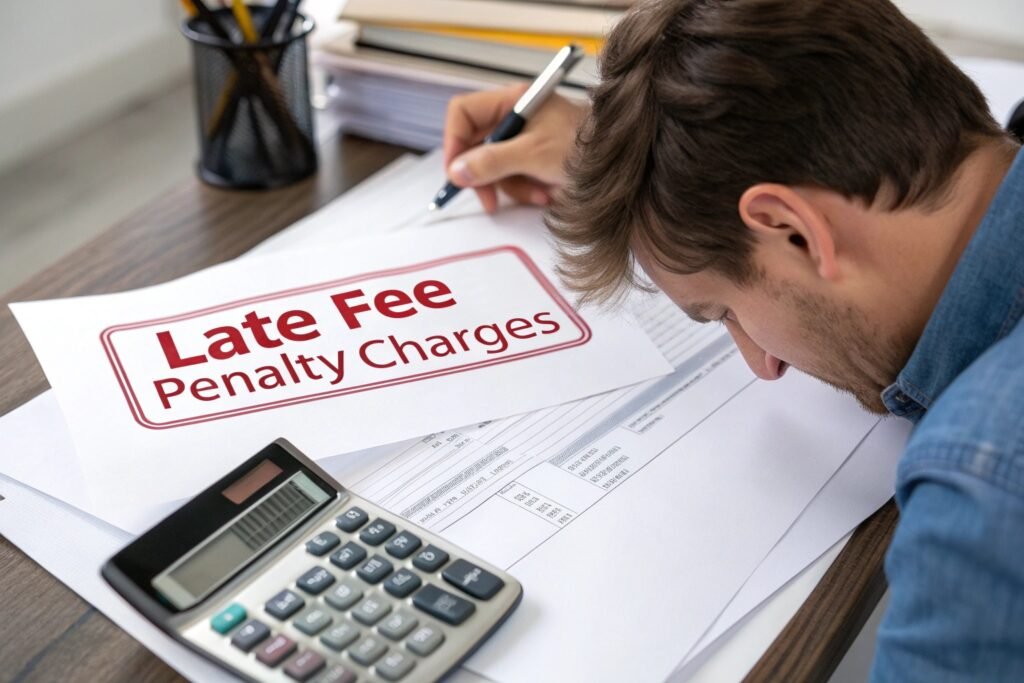

The cost of late shipments for global importers

Timeliness isn’t just about efficiency—it directly affects profitability.

Late shipments increase logistics costs, trigger penalties, and damage supplier and customer relationships. Importers face financial and reputational losses when freight is delayed.

What are the real costs of shipping delays?

- Higher logistics charges: Demurrage, detention, rush trucking

- Air freight upgrades: To replace delayed ocean cargo

- Lost retail revenue: Missed product launches or seasonal windows

- Supplier disputes: If delay affects contract terms

One client importing promotional drinkware for a U.S. brand faced a $50,000 contract penalty because the goods arrived 3 days late. We helped them renegotiate shipping terms to include a buffer and added faster customs clearance for the next order.

| Delay Impact | Typical Cost Example |

|---|---|

| Demurrage (3 days) | $300–$900 per container |

| Rebooking air freight | 3x the cost of ocean freight |

| Lost retail window | 15–30% loss in seasonal revenue |

| Missed Amazon window | Listing suspension, ranking drop |

How can forwarders help reduce these risks?

- Build buffer time into shipping schedules

- Monitor and rebook proactively

- Recommend alternate routes or carriers

- Help file claims if delays occur

With GeeseCargo, clients gain both speed and support. We don’t just ship—we shield your bottom line.

Role of scheduling in reliable freight delivery

The best deliveries don’t happen by accident—they’re planned down to the day and hour.

Freight scheduling involves booking carriers early, aligning warehouse availability, and coordinating customs clearance. A reliable schedule is the foundation of on-time delivery.

Why does good scheduling matter so much?

Without it, you risk:

- Missing vessel cutoffs

- Overlapping truck bookings

- Poor warehouse intake coordination

- Unexpected customs bottlenecks

We help clients:

- Reserve vessel space 2–3 weeks ahead

- Book truckers the moment cargo clears

- Notify warehouse teams 24–48 hours in advance

| Scheduling Task | Timeline for Best Results |

|---|---|

| Vessel booking | 10–14 days before ETD |

| Trucking appointment | At customs release or 1 day prior |

| Warehouse delivery slot | 48 hours before delivery |

| Customs pre-clearance | Submit documents 3–5 days in advance |

How does GeeseCargo manage scheduling?

We use:

- Shared booking calendars

- Google Sheets with milestone targets

- Email + WeChat for faster confirmations

- Real-time alerts for any changes

By keeping all parties aligned, we minimize reschedules and shorten total transit times.

How forwarders help meet tight delivery deadlines

When timing is critical—like for holiday shipments or product launches—importers rely on forwarders to deliver, no excuses.

Freight forwarders meet tight deadlines by choosing the fastest modes, securing early bookings, rerouting when necessary, and tracking every detail of the journey.

What tactics do we use to meet urgent delivery needs?

- Split shipments: Air freight part, sea freight the rest

- Book priority vessels: Avoid slower carrier schedules

- Use alternate ports: Bypass congestion or closures

- Pre-clear customs: Submit documents before arrival

- Coordinate last-mile delivery: Reserve trucks at the right time

A Canadian importer of Christmas ornaments needed goods in stores by mid-November. Their factory finished late. We air freighted 2 CBM for immediate launch and sea shipped the rest. The retailer met its deadline—and rebooked with us the following year.

| Deadline Scenario | Our Solution |

|---|---|

| Late factory production | Use partial air + sea freight |

| Port backlog | Reroute to alternate port |

| Tight Amazon cutoff | Book direct FBA delivery |

| Sensitive product launch | Match delivery with PR schedule |

How do we communicate during these high-pressure shipments?

- Daily status updates

- Shipment countdown checklists

- Custom Slack or WhatsApp channels

- Real-time document sharing

No guessing. No radio silence. Just clear, reliable execution.

Conclusion

Timely freight forwarding protects your inventory, budget, and brand reputation. At GeeseCargo, we treat your delivery deadlines as our own—because in global trade, being on time is everything.