When importers like Ron plan freight from China to the U.S., timeliness is non-negotiable. Missed delivery windows can delay retail launches, cause stockouts, and increase demurrage fees. Yet, one of the most overlooked factors is port selection.

Choosing the right port can mean the difference between a smooth 18-day delivery and a delayed 30-day detour. Forwarders help you navigate port congestion, proximity, and customs speed to optimize total transit time.

At GeeseCargo, we've seen how strategic port decisions impact overall shipment performance. Let’s explore why port choice is a critical logistics decision.

How Does Port Congestion Impact Delivery Schedules?

Port congestion is a silent killer in global freight. A vessel may arrive on time, but delays at port can add days or weeks to your schedule.

By avoiding congested ports and selecting terminals with fast throughput, forwarders minimize idle time and speed up delivery.

What Ports Are Prone to Frequent Congestion?

High-volume ports like Los Angeles-Long Beach or Shanghai often experience congestion, especially during peak seasons or labor slowdowns. In 2021, West Coast backlogs left importers waiting 2–3 extra weeks.

We help clients reroute to alternate ports like Oakland or Tianjin when early indicators show congestion building.

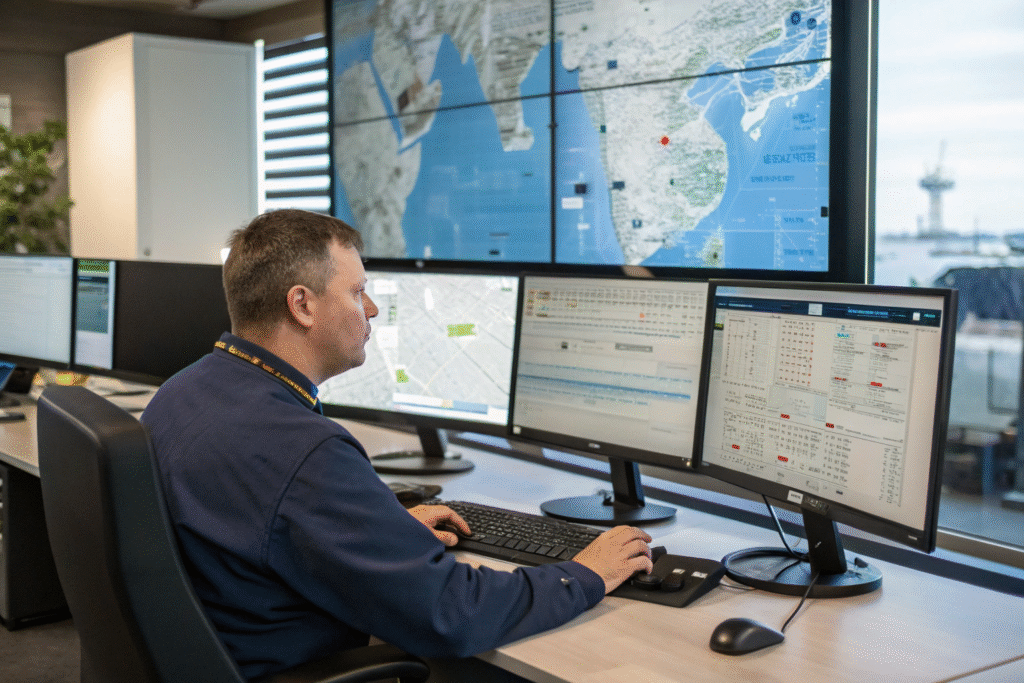

How Do Forwarders Monitor Port Conditions?

We track congestion data through platforms like MarineTraffic and PortCast, then advise clients in real-time. This helped Ron avoid a 7-day delay last quarter by switching from Ningbo to Yantian.

Our analytics include dwell times, gate availability, and clearance speed across top routes.

Does Port Location Affect Inland Transit Efficiency?

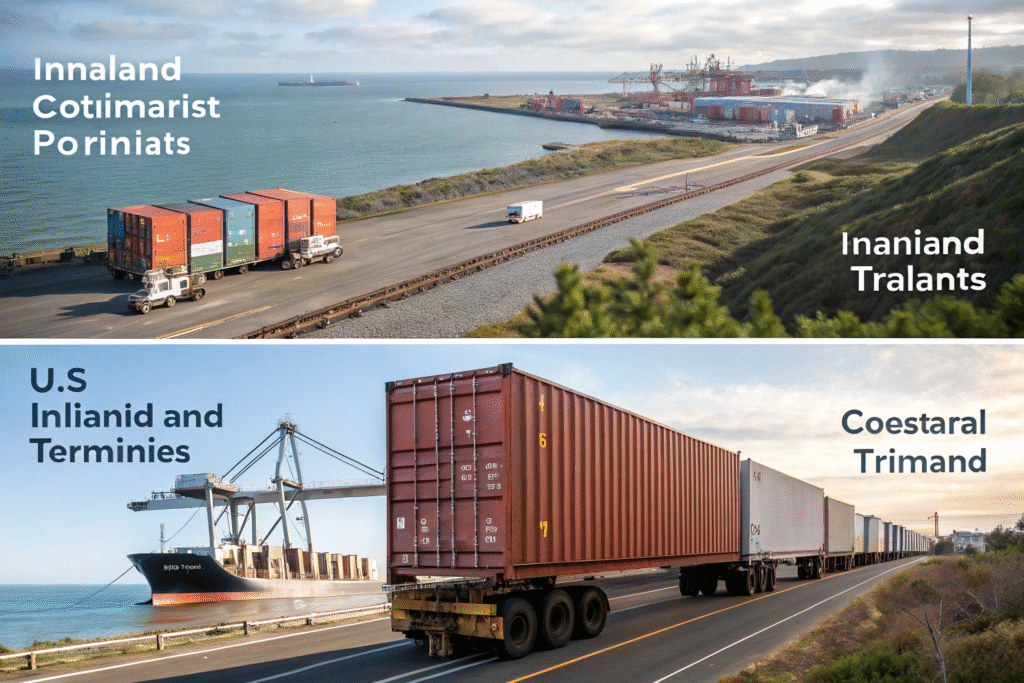

Port location doesn’t just affect ocean transit—it determines how fast and affordably your goods reach inland warehouses.

Choosing a port closer to your final destination or linked with strong rail/road infrastructure can reduce total delivery time and cost.

What’s the Difference Between East and West Coast Ports?

Shipping to the West Coast (e.g., Los Angeles) is typically faster by sea—about 12–18 days—but may require longer truck/rail delivery to the East Coast. East Coast ports like Savannah or Newark take 25–30 days by sea but cut inland miles for U.S. East Coast receivers.

We help clients choose based on final warehouse ZIP codes and available intermodal rail services.

Can Port Selection Reduce Domestic Shipping Costs?

Absolutely. For example, if Ron’s warehouse is in Dallas, shipping via Houston instead of L.A. cuts both transit time and trucking distance. We use lane optimization tools like Project44 to make cost-effective port choices.

How Do Customs Processing Speeds Vary by Port?

Not all ports clear goods at the same pace. Clearance speed depends on customs staffing, infrastructure, and even port-specific policies.

Ports with faster customs processing ensure your goods move quickly from vessel to truck, saving valuable time.

Which U.S. Ports Are Known for Efficient Customs Clearance?

Ports like Savannah, GA and Charleston, SC are recognized for efficient container handling and customs cooperation. We’ve had shipments cleared within 48 hours at these locations, compared to 4–5 days at L.A. or Seattle.

We also rely on ACE Portal pre-filing to speed up clearance no matter the port.

How Can Pre-Clearing Help Avoid Port Delays?

We submit documents digitally before the cargo arrives using platforms like CargoWise and Freightos Customs. This cuts down on physical inspections and releases cargo immediately upon arrival.

Port choice matters—some terminals prioritize pre-cleared goods for early unloading.

How Do Forwarders Align Port Choice With Freight Strategy?

Choosing the right port isn’t just about geography—it’s about matching your supply chain priorities.

Freight forwarders choose ports based on total delivery timeline, budget, sailing schedule, customs risk, and client warehouse needs.

What Port Factors Should Be Considered?

We assess several variables:

| Factor | Description |

|---|---|

| Sailing Frequency | How often vessels depart to/from the port |

| Dwell Time | Average time cargo stays before pickup |

| Inland Cost | Trucking or rail costs from port to warehouse |

| Customs Speed | Clearance delays, staffing, pre-clearance capability |

| Risk Profile | Congestion, strike potential, weather |

We tailor port strategy using tools like Flexport and INTTRA to create data-backed recommendations.

Can Port Strategy Change With Business Needs?

Yes. When Ron scaled to multi-warehouse fulfillment, we shifted his shipping pattern—using West Coast ports for fast-mover SKUs and East Coast for slower inventory. Our port strategy evolves with client needs, peak seasons, and tariff shifts.

We also advise clients during blank sailing periods when carriers cancel certain routes, allowing us to pivot ports in time.

Conclusion

Choosing the right port is one of the smartest ways to improve delivery speed, reduce costs, and minimize customs issues. A strategic port decision is more than a geographic choice—it’s a logistics advantage.

At GeeseCargo, we help importers select the optimal port for every shipment, factoring in sailing schedules, inland delivery routes, customs efficiency, and seasonal congestion. Whether you’re shipping bulk freight or e-commerce orders, your port matters.

Let us help you choose right—and arrive on time, every time.