In global trade, ocean freight remains the most cost-efficient method for transporting high-volume cargo. Yet the booking process involves multiple stakeholders, strict documentation, and regulatory compliance. For logistics and supply chain professionals, understanding each stage in detail is essential to mitigate risk, optimize transit time, and control landed cost.

The process of booking ocean freight includes carrier or NVOCC selection, provision of shipment details, securing vessel space, preparing mandatory documents, arranging export and import customs clearance, and monitoring cargo through end-to-end visibility systems.

From my experience with U.S. importers handling apparel and electronics, a structured booking workflow reduces demurrage, avoids detention, and prevents costly delays at both origin and destination ports.

How Do You Initiate the Booking Process with a Freight Forwarder?

The booking process begins with the shipper submitting detailed shipment instructions (SI) to the freight forwarder or NVOCC. This includes commodity description, HS/HTS code, total CBM, gross weight, Incoterms, and port pairs.

Based on this data, the forwarder determines whether Full Container Load (FCL) or Less than Container Load (LCL) service is more cost-effective, and provides a booking confirmation upon acceptance.

For example, one U.S. client underestimated CBM requirements and initially considered LCL. By reviewing cubic capacity thresholds, we switched to FCL, reducing per-unit freight cost by 18%.

Why Is Accurate Shipment Data Critical?

Maersk emphasizes that incorrect dimensions or weight can trigger rebooking, mis-stowage, or container rollovers.

How Do FCL and LCL Impact Supply Chain Strategy?

As Freightos explains, FCL minimizes handling risk and delays, while LCL provides flexibility for SMEs with smaller shipment volumes. Strategic choice directly impacts supply chain efficiency.

What Documents Are Essential for Ocean Freight?

Proper documentation ensures compliance with international trade law and prevents customs holds. The critical documents include:

- Bill of Lading (B/L): Issued by the carrier or forwarder, it serves as a contract of carriage, title to goods, and receipt.

- Commercial Invoice and Packing List: Required for customs valuation and tariff calculation.

- Certificates (e.g., Certificate of Origin, phytosanitary certificate): Mandatory depending on commodity and regulatory requirements.

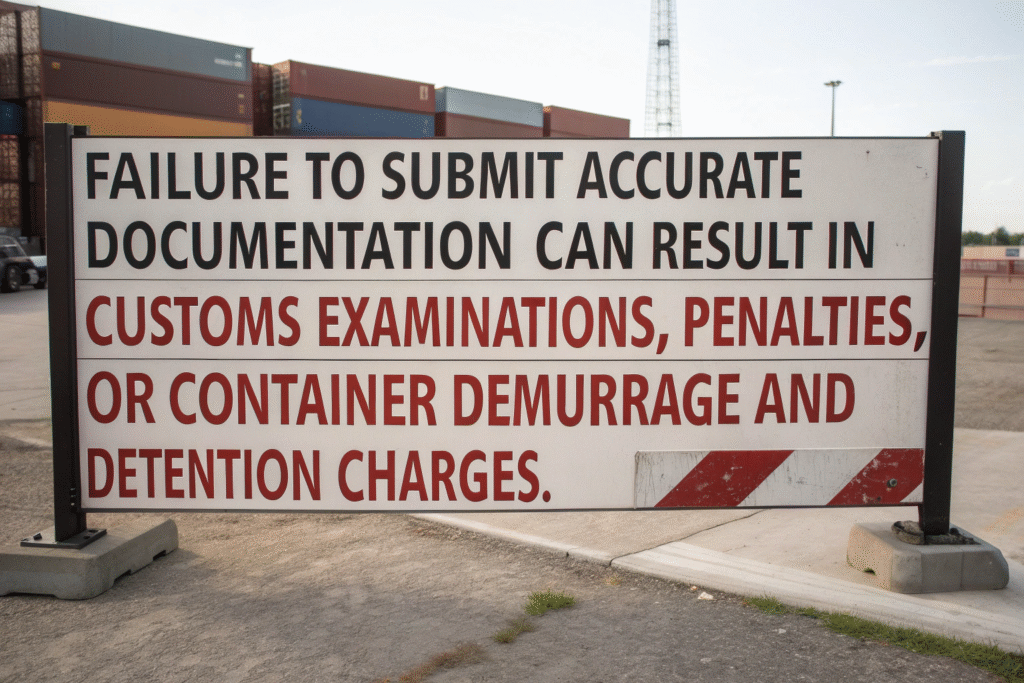

Failure to submit accurate documentation can result in customs examinations, penalties, or container demurrage and detention charges.

One apparel importer failed to provide a textile declaration, leading to a seven-day hold by U.S. Customs and Border Protection (CBP). After implementing a pre-shipment document review protocol, future shipments cleared seamlessly.

Why Is the Bill of Lading the Most Critical Document?

The Bill of Lading validates title and legal ownership of goods. Errors here can prevent release of cargo at the destination.

How Do Customs Documents Affect Clearance?

CBP.gov stresses that incorrect HS/HTS classification or undervaluation increases the risk of inspection and penalties. Forwarders often utilize HTS Search to ensure compliance.

How Do Vessel Scheduling and Booking Confirmations Work?

After shipment instructions are submitted, the forwarder reviews sailing schedules, carrier alliances, and transshipment requirements. Vessel space is secured through a booking confirmation, which includes the container cut-off date, free time at origin terminal, and estimated arrival.

Booking confirmations act as contractual guarantees of space allocation. During peak season, advance booking is crucial to avoid rolled cargo and premium rate surcharges.

A client exporting furniture to the U.S. East Coast secured space 30 days in advance, preventing peak season surcharges that exceeded $1,000 per container.

How Do Carriers Manage Capacity Allocation?

Hapag-Lloyd explains that carriers implement yield management during high demand. Early bookings reduce the risk of equipment shortages and vessel rollovers.

Why Is Schedule Reliability a KPI?

Sea-Intelligence tracks global schedule reliability. Forwarders use this data to benchmark carriers and mitigate transit risks.

How Do Customs Clearance and Cargo Tracking Integrate with Ocean Freight?

Customs clearance is required at both export and import stages. Forwarders coordinate export declarations (e.g., ENS/AMS filing) and destination entry processes, including ISF filing for U.S. imports.

Cargo visibility platforms integrated with carriers’ APIs allow real-time updates on ETAs, port congestion, and customs status.

I assisted a client importing electronics who used predictive ETA dashboards to schedule labor allocation at his distribution center, reducing idle warehouse costs by 12%.

How Does Customs Clearance Operate?

Agencies like CBP.gov require timely ISF (Importer Security Filing) and duty payments before release. Forwarders ensure proper HTS codes and trade compliance.

Why Is Tracking Technology Valuable?

Solutions from DHL and UPS provide end-to-end visibility. Supply chain managers leverage this data to reduce uncertainty and optimize last-mile distribution.

Conclusion

The process of booking ocean freight is a structured workflow involving carrier selection, shipment instructions, documentation, vessel scheduling, customs clearance, and visibility management. For logistics professionals, precision in each stage minimizes demurrage, reduces detention, and improves landed cost predictability. Partnering with an experienced freight forwarder ensures compliance, optimizes vessel allocation, and provides real-time visibility—ultimately strengthening overall supply chain efficiency.