When one of our clients had a $120,000 shipment of smart home devices held at customs for lacking proper FCC certification, I realized how many importers underestimate US electronics regulations. As founder of GeeseCargo with extensive experience in electronics imports, I've witnessed how regulatory compliance isn't just paperwork—it's the foundation of successful market entry. Understanding these requirements prevents costly delays, seizures, and potential penalties.

US electronics imports must comply with FCC regulations for electromagnetic emissions, UL safety standards, energy efficiency requirements, and proper labeling. Specific products may need additional certifications from FDA (medical devices), DOE (energy consumption), or CPSC (safety). Non-compliance can result in refused entry, forced recalls, or penalties up to $100,000 per violation.

Electronics represent one of the most regulated import categories due to safety concerns, interference potential, and energy conservation mandates. Navigating this regulatory landscape requires understanding which agencies govern your specific products and what certifications they require.

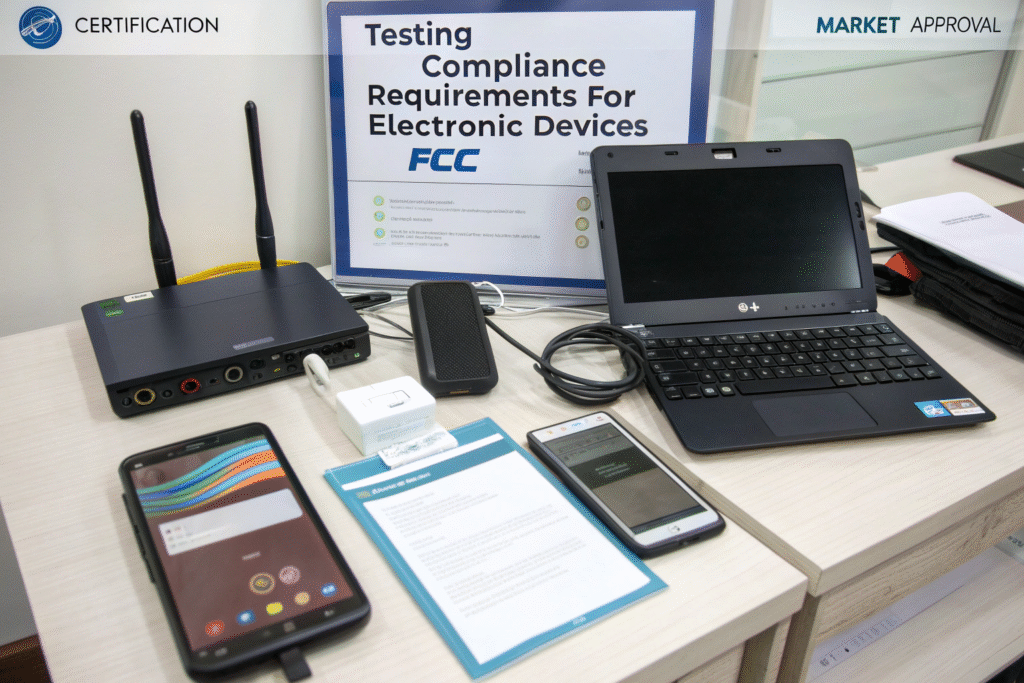

What FCC Requirements Apply to Electronic Devices?

The Federal Communications Commission regulates electronic devices that could interfere with radio communications, encompassing most modern electronics with digital components or wireless capabilities.

Which Devices Require FCC Certification Versus Declaration?

Intentional radiators like Wi-Fi routers, Bluetooth devices, and cellular phones require FCC Certification. This involves testing by an accredited laboratory and formal certification through the FCC's Telecommunication Certification Body (TCB) process, resulting in a unique FCC ID that must appear on the product.

Unintentional radiators including computers, switching power supplies, and digital electronics typically need FCC Declaration of Conformity. The manufacturer performs required testing and creates documentation demonstrating compliance, which must be provided to importers and available for FCC inspection.

Exempted devices are limited to specific categories with no RF potential. Some basic electronics without high-frequency digital circuits or oscillators above 9 kHz may be exempt, but most modern electronics containing microprocessors or digital components require FCC compliance.

What Are the FCC Labeling and Documentation Requirements?

FCC identification must be permanently affixed to the device. Certified devices require the FCC ID (format: XXXXXXXXXXX), while declared devices need the FCC logo and compliance statement. The labeling must be visible without removing covers and survive the product's expected lifetime.

User manual statements must include specific compliance language. Devices typically require statements about interference acceptance and potential interference to other devices, along with instructions for maintaining compliance if user modifications are possible.

Technical documentation must be maintained for at least five years. This includes test reports, design specifications, and compliance records that demonstrate how the product meets applicable FCC standards.

What Safety Standards and Certifications Are Mandatory?

Beyond electromagnetic compliance, electronics must meet safety standards that protect consumers from shock, fire, and physical injury hazards.

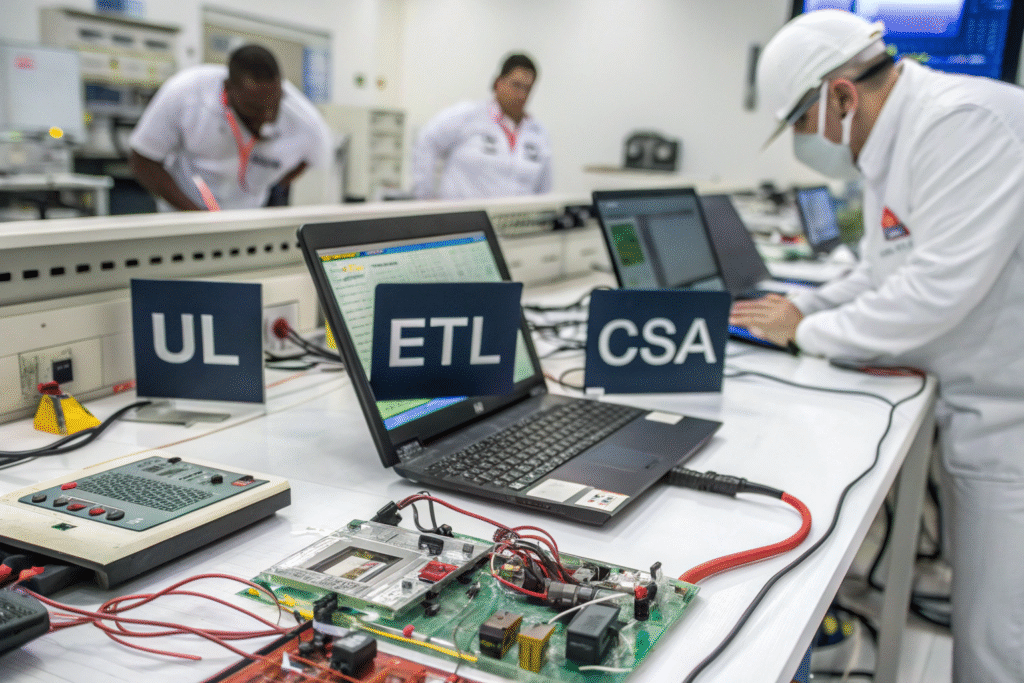

When Is NRTL Certification Required?

OSHA regulations mandate Nationally Recognized Testing Laboratory certification for workplace equipment. While not explicitly required for consumer products, most retailers and marketplaces demand UL, ETL, or equivalent certification, making it de facto mandatory for market access.

Specific product categories have explicit safety certification requirements. Products like power supplies, battery chargers, and household appliances typically require safety certification, while accessories may have more flexible requirements.

Component-level certification may satisfy requirements for finished products. Using NRTL-certified power supplies, transformers, and other components can simplify the certification process for assembled electronic products.

What Are the Key Safety Standards for Common Electronics?

IT equipment follows UL 62368-1, the hazard-based safety standard replacing older UL 60950-1. This standard applies to computers, servers, networking equipment, and office electronics, focusing on energy source classification and hazard prevention.

Household appliances require UL 60335 series compliance. This extensive standard family covers everything from kitchen appliances to personal care devices, with specific requirements based on product type and usage environment.

Audio/video equipment follows UL 60065 for entertainment electronics. Televisions, speakers, amplifiers, and similar consumer electronics have specific safety requirements distinct from IT equipment.

How Do Energy Efficiency Regulations Impact Electronics?

Multiple US agencies regulate energy consumption for electronic devices, with requirements varying by product category and energy usage characteristics.

What DOE Regulations Apply to Electronic Products?

External power supplies have mandatory efficiency standards under DOE Level VI. Nearly all electronics containing external power supplies must meet minimum efficiency and no-load power consumption requirements, with specific testing and certification mandates.

Battery charppers fall under DOE battery charger standards. Products containing rechargeable batteries must meet energy efficiency requirements during charging cycles, affecting design considerations for smartphones, laptops, and portable electronics.

Future standards are expanding to additional product categories. The DOE continuously evaluates new products for potential regulation, with ongoing proceedings covering everything from gaming consoles to network equipment.

How Does ENERGY STAR Certification Work?

Voluntary program offers market differentiation for efficient products. While not mandatory, ENERGY STAR certification is often required by government purchasers and valued by environmentally conscious consumers, making it commercially important.

Partnering requirements mandate manufacturer participation agreements. Companies must become ENERGY STAR partners and follow specific testing protocols using accredited laboratories to qualify products for certification.

Updated specifications regularly raise efficiency thresholds. ENERGY STAR requirements typically become more stringent every 2-3 years, requiring product redesign or component changes to maintain certification.

What Special Regulations Apply to Specific Electronic Categories?

Beyond general requirements, certain electronics face additional regulations based on their functionality, components, or potential risks.

When Does FDA Regulation Apply to Electronics?

Medical devices require FDA clearance or approval based on classification. Electronics with medical claims or functionality typically need 510(k) clearance or Premarket Approval, with rigorous documentation and quality system requirements.

Radiation-emitting electronics beyond FCC scope need FDA approval. Products like microwave ovens, ultraviolet lamps, and laser products require additional FDA regulation under the Radiation Control for Health and Safety Act.

Combination products with drug/device or device/biological components face complex regulation. Smart pill bottles, drug delivery systems, and diagnostic testers may require both FDA device and drug approvals.

What Are the Battery and Environmental Regulations?

Battery transportation follows DOT and IATA dangerous goods regulations. Lithium batteries have specific packaging, labeling, and documentation requirements for air and ocean transport, with frequent updates as safety standards evolve.

State-level regulations include California Proposition 65 warnings. Electronics containing substances like lead, cadmium, or phthalates may require warning labels if they exceed safe harbor levels, even when fully compliant with federal regulations.

Recycling requirements vary by state for certain electronics. Several states mandate manufacturer recycling programs for covered electronics, requiring registration and compliance with specific disposal and recycling protocols.

What Documentation and Recordkeeping Is Required?

Proper documentation demonstrates compliance and must be maintained for potential inspection by regulators, customers, or customs authorities.

What Must Be Included in Technical Documentation?

Test reports from accredited laboratories form the compliance foundation. These must cover all applicable standards using proper test methods and include complete product identification, test dates, and laboratory accreditation details.

Design documentation shows how compliance is built into the product. Schematics, block diagrams, component specifications, and manufacturing processes demonstrate that the product will remain compliant through production.

Risk assessments and compliance matrices identify applicable requirements. Documenting the process for determining which regulations apply and how each requirement is addressed provides crucial audit evidence.

How Long Must Compliance Records Be Maintained?

General requirement is five years from last product shipment. Most regulations mandate maintaining compliance records for several years, with specific timeframes varying by agency and regulation type.

Product-specific timelines may extend beyond five years. Medical devices, children's products, and other higher-risk categories often require longer retention periods, sometimes spanning the product's expected lifespan.

Accessibility requirements mean records must be producible within days. While digital records are acceptable, they must be readily available for inspection without extensive preparation or retrieval efforts.

Conclusion

US electronics regulations create a complex but navigable framework that prioritizes safety, interference prevention, and energy conservation. The most successful importers integrate compliance considerations into their product development process rather than treating them as last-minute hurdles.

At GeeseCargo, we've helped hundreds of clients navigate electronics regulations, transforming compliance from a barrier into a competitive advantage. The companies that excel begin regulatory assessment during product design, engage experienced testing laboratories early, and maintain meticulous documentation throughout the product lifecycle.

Begin your compliance journey by identifying all regulations that apply to your specific products, then develop a testing and certification plan that addresses each requirement systematically. Remember that in electronics importing, compliance isn't just about avoiding penalties—it's about building trustworthy products that succeed in the competitive US market.