When one of our automotive clients discovered their "duty-free" shipment to Mexico actually faced 18% import duties due to incorrect origin certification, they learned firsthand about Mexico's complex logistics environment. As founder of GeeseCargo with extensive cross-border experience, I've witnessed how Mexico's unique regulatory framework, infrastructure limitations, and security concerns create distinct challenges that differ significantly from other North American markets.

Shipping to Mexico presents challenges including complex customs procedures, security risks in certain regions, infrastructure limitations, documentation requirements, and cross-border coordination. Successful shippers typically experience 2-5 day customs clearance delays, face 5-15% cargo theft risks in high-risk areas, and navigate 15-25 different documents per shipment depending on product type.

Mexico offers tremendous opportunity with its growing manufacturing base and proximity to the US, but understanding its specific logistics landscape is essential for efficient operations. Companies that master Mexican logistics typically achieve 25-40% cost advantages over competitors struggling with persistent operational challenges.

What Are the Key Customs and Regulatory Challenges?

Mexico's customs system combines modern automation with persistent bureaucratic requirements that create compliance hurdles.

How Does Mexico's Customs Process Differ from Other Markets?

The Pedimento de Importación serves as the comprehensive customs declaration. This complex document requires detailed product information, valuation data, and regulatory compliance declarations that exceed standard commercial invoice requirements.

Official customs brokers (agentes aduanales) are mandatory for most imports. Unlike the US where self-filing is possible, Mexico requires licensed customs brokers to process imports, adding both cost and coordination complexity.

Multiple government agencies have import authority beyond just customs. Depending on the product, shipments may require approvals from COFEPRIS (health), SEMARNAT (environment), SAGARPA (agriculture), or other specialized agencies.

What Are the Most Common Customs Compliance Pitfalls?

Classification under Mexico's Tarifa de la Ley de los Impuestos Generales de Importación y Exportación requires specific expertise. Mexico's tariff system, while harmonized with the HS system, has unique interpretations and requirements that differ from US or EU classifications.

Valuation verification follows strict rules with limited flexibility. Mexican customs carefully scrutinizes transaction values and may reassess based on their reference prices, particularly for commodities and high-volume products.

Rules of origin documentation must be perfect for preferential treatment. Even minor errors in certificates of origin or supporting documentation can void NAFTA/USMCA benefits, resulting in full duty application.

What Security Concerns Impact Mexican Logistics?

Security represents one of the most significant challenges, with varying risk levels across different regions and transportation routes.

Where Are the Highest Security Risks Located?

Theft hotspots concentrate around major manufacturing zones and ports. Areas like the State of Mexico, Michoacán, and specific corridors near Laredo and Monterrey experience higher incident rates, particularly for high-value goods.

Port areas face sophisticated cargo theft operations. Major ports like Manzanillo and Veracruz have organized theft rings that target specific commodities using insider information and sophisticated methods.

Border crossing points present unique security challenges. The US-Mexico border regions see cargo theft, document fraud, and product diversion despite heavy security presence.

What Security Measures Effectively Reduce Risks?

GPS tracking with real-time monitoring provides visibility and deterrence. Modern tracking systems with geofencing capabilities can alert to unauthorized stops or route deviations, enabling rapid response.

Armed escorts are necessary in certain high-risk regions. For high-value shipments or transportation through dangerous areas, professional security escorts significantly reduce hijacking risks.

Secure parking facilities with verified protocols prevent theft during stops. Using certified secure parking locations for mandatory rest stops prevents the most common theft method—taking entire trucks from unattended parking areas.

What Infrastructure Limitations Affect Operations?

Mexico's infrastructure has improved significantly but still presents challenges, particularly outside major industrial corridors.

How Do Port Limitations Impact Import Efficiency?

Port congestion varies significantly by location and season. While major ports like Manzanillo and Lázaro Cárdenas have expanded capacity, they still experience peak season congestion that can delay vessels by 2-4 days.

Equipment availability challenges affect container movements. Limited chassis pools, specialized equipment shortages, and imbalanced container flows can create 3-5 day delays in obtaining equipment for inland movement.

Intermodal connectivity limitations increase costs and transit times. Rail connections from ports to interior markets are limited, forcing greater reliance on more expensive truck transport for many destinations.

What Road Infrastructure Challenges Exist?

Toll road quality versus free road safety presents difficult choices. Mexico's toll roads (cuotas) offer better conditions but significantly higher costs, while free roads (libres) may have safety and condition issues.

Mountainous terrain affects transit times and costs. Routes from major ports to central manufacturing hubs like Querétaro or San Luis Potosí involve significant elevation changes that impact fuel consumption and transit times.

Border crossing infrastructure creates bottlenecks. Despite improvements, border crossings like Laredo and El Paso still experience 8-24 hour delays during peak periods due to capacity limitations.

What Documentation and Compliance Issues Cause Delays?

Mexico's documentation requirements are extensive and unforgiving of errors, making proper preparation essential.

What Are the Most Critical Documentation Requirements?

The Pedimento de Importación requires 40+ data elements for accurate completion. This comprehensive document demands precise product descriptions, valuation details, classification codes, and regulatory compliance information.

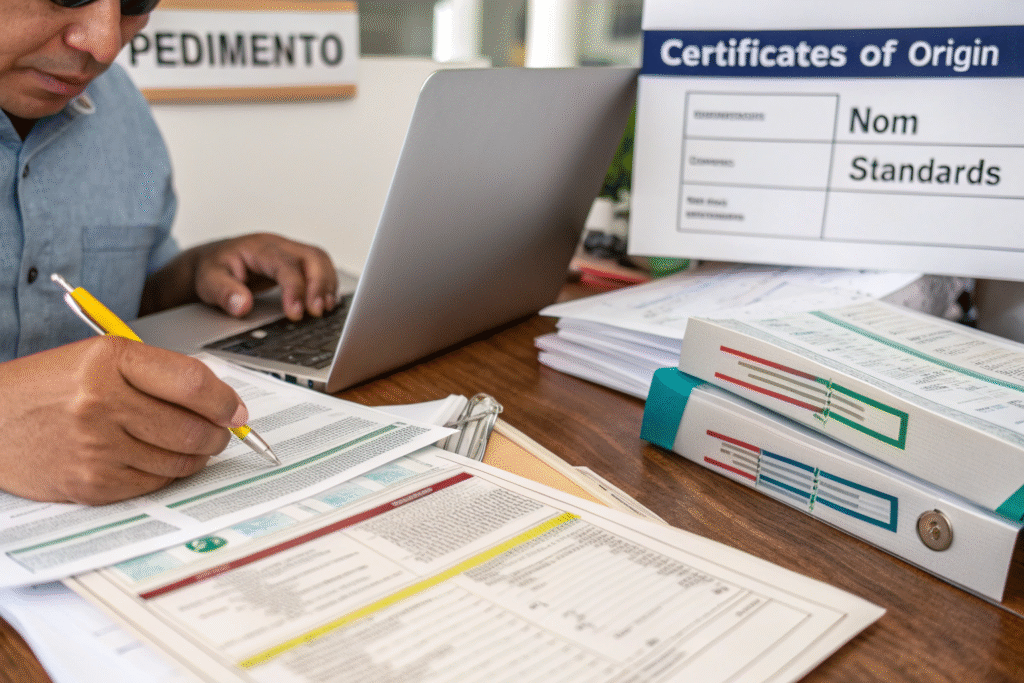

NOM standards certifications are required for many products. Mexico's mandatory standards (Normas Oficiales Mexicanas) apply to electronics, appliances, medical devices, food products, and many other categories.

Proof of origin documentation must be perfect for preferential treatment. USMCA certificates require specific data elements and supporting documentation to qualify for reduced or zero duty rates.

What Common Documentation Errors Cause the Longest Delays?

Incorrect harmonized system codes trigger manual reviews and delays. Even small classification errors can cause customs to reject entire shipments, requiring re-submission and creating 3-5 day delays.

Missing or incorrect certificates for regulated products stop clearance completely. Products subject to NOM standards or other regulations face immediate holds if proper certifications aren't provided.

Value declaration discrepancies prompt extensive verification. Differences between declared values and customs reference prices trigger detailed investigations that can delay shipments for weeks.

How Can You Overcome These Logistics Challenges?

Strategic approaches and specific operational practices can mitigate Mexico's logistics challenges effectively.

What Partner Selection Criteria Maximize Success?

Experienced customs brokers with strong relationships streamline clearance. Brokers with established relationships at specific ports and proven track records with your product category can navigate complexities more effectively.

Carriers with Mexican operating authority and security protocols ensure reliability. Trucking companies with owned equipment, vetted drivers, and robust security measures provide more consistent service than brokers using subcontracted carriers.

Warehouse partners with cross-border expertise facilitate distribution. Mexican warehouses understanding both US shipping practices and Mexican distribution requirements smooth the transition across the border.

What Operational Practices Reduce Challenges?

Advanced document preparation and review prevents clearance delays. Having all documents prepared, reviewed by Mexican experts, and submitted before shipment arrival eliminates the most common cause of customs delays.

Strategic routing avoids high-risk areas and congestion points. Planning routes that bypass known theft hotspots and congestion areas, even with slightly longer distances, typically improves reliability and security.

Consolidated shipping reduces per-unit costs and complexity. Combining smaller shipments into full truckloads or container loads minimizes border crossing complexity and reduces per-unit transportation costs.

What Are the Cost Implications of These Challenges?

Understanding the financial impact helps businesses budget accurately and identify improvement opportunities.

What Are the Typical Cost Components Beyond Basic Freight?

Customs brokerage and import duties typically add 8-15% to product cost. Brokerage fees, import duties, VAT, and other customs-related charges represent significant additional costs beyond transportation.

Security measures add 3-8% to transportation costs. GPS tracking, secure parking, armed escorts, and insurance premiums necessary for secure operations increase transportation expenses.

Infrastructure-related costs include tolls and border crossing fees. Toll roads, cross-docking, and border processing fees can add 5-12% to basic freight costs depending on routes and destinations.

How Do Delays and Errors Impact Total Costs?

Demurrage and storage charges accumulate rapidly during delays. Customs delays typically generate $100-300 per day in container demurrage and storage charges that quickly erase profit margins.

Inventory carrying costs increase with longer transit times. The extended cash-to-cash cycle from longer border crossings and customs processing increases working capital requirements.

Error correction costs exceed prevention investment. Fixing customs errors, reshipping rejected products, or addressing compliance issues typically costs 3-5 times more than proper initial compliance.

Conclusion

Shipping to Mexico presents distinct challenges that require specialized knowledge and tailored approaches rather than simply extending US logistics practices. The most successful companies treat Mexican logistics as a specialized competency, investing in local expertise, robust processes, and strategic partnerships that address the unique regulatory, security, and infrastructure landscape.

At GeeseCargo, we've helped clients reduce Mexican shipping costs by 25-40% while improving reliability metrics by 35-60% through systematic approaches that address these specific challenges. The key is recognizing that Mexico isn't just "the US with different paperwork"—it's a unique logistics environment that rewards specialized knowledge and local relationships.

Begin your Mexican logistics improvement by conducting a thorough assessment of your current challenges, then develop targeted strategies that address your highest-impact pain points. Remember that in Mexican logistics, prevention and preparation are dramatically more effective than reaction—the modest investment in proper compliance, security, and partner selection typically returns 5-10x in avoided costs and disruptions.