When one of our e-commerce clients shifted 40% of their shipments from East Coast to West Coast ports last quarter, they saved $28,000 in transportation costs while improving delivery times by 6 days. As founder of GeeseCargo, I've analyzed thousands of shipping routes and can confirm that the cost difference is real and significant—but the optimal choice depends entirely on your specific supply chain requirements.

Shipping from China to US West Coast ports is typically 25-40% cheaper than East Coast routes due to shorter transit distances and higher shipping volume. However, total landed costs must account for final inland transportation, inventory carrying costs, and potential congestion-related delays that can erase initial ocean freight savings.

The West Coast versus East Coast decision involves more than comparing ocean freight rates. Understanding the total cost equation requires analyzing transit times, reliability, inland transportation, and how these factors interact with your inventory strategy and customer location patterns.

What Are the Direct Ocean Freight Cost Differences?

The fundamental cost disparity stems from simple geography: Shanghai to Los Angeles covers approximately 6,500 nautical miles, while Shanghai to New York spans 10,800 nautical miles. This distance differential creates substantial cost variations.

How Significant Are the Base Freight Rate Variations?

West Coast routes typically cost $1,800-$2,800 per 40-foot container, while East Coast routes range from $3,200-$4,200 for the same shipment. This 35-50% premium for East Coast shipments reflects both longer distances and additional canal charges.

The Panama Canal tolls add $150,000-$300,000 per vessel transit, which carriers factor into their pricing models. Suez Canal routes avoiding Panama still face similar toll structures and longer distances, maintaining the East Coast premium.

Seasonal fluctuations affect both routes differently. West Coast rates spike during August-October peak season, while East Coast experiences sharper increases during January-March as retailers build summer inventory. Understanding these patterns enables strategic shipment timing.

How Do Surcharges Differ Between Routes?

Fuel adjustment factors vary by route distance and current bunker prices. East Coast routes typically carry 15-25% higher fuel surcharges due to increased consumption on longer voyages.

Peak season surcharges impact West Coast more dramatically, often adding $800-$1,200 per container from August through October. East Coast peak surcharges are generally lower but extend over longer periods.

Congestion surcharges have become increasingly common, particularly for West Coast ports during labor negotiations or infrastructure disruptions. These unpredictable costs can temporarily erase the West Coast cost advantage.

How Do Transit Times and Reliability Compare?

Time-definite supply chains require understanding not just average transit times, but reliability metrics that affect inventory planning and customer service levels.

What Are the Typical Transit Time Ranges?

West Coast transit times average 14-18 days from Chinese ports to LA/Long Beach, with minimal variance for reliable carriers. This predictability enables tighter inventory management and faster response to demand changes.

East Coast via Panama Canal requires 28-35 days, while Suez Canal routes take 30-38 days. The longer transit times increase in-transit inventory carrying costs and require larger safety stocks.

All-water East Coast services offer the most consistent schedules but longest transit times. Mini-land bridge services (West Coast port with rail to East Coast) provide intermediate transit times of 21-26 days but introduce intermodal complexity.

How Does Reliability Impact Total Costs?

West Coast routes demonstrate 85-90% on-time performance under normal conditions, while East Coast routes achieve 80-85% reliability. The 5-10% reliability difference translates to higher safety stock requirements for East Coast supply chains.

Weather disruptions affect East Coast more significantly, particularly during hurricane season (June-November). Winter weather also impacts rail and truck movements from West Coast ports, creating seasonal reliability challenges.

Port labor stability varies by coast, with West Coast experiencing more frequent labor disputes but higher automation levels. East Coast ports generally have better labor relations but less efficient operations in some locations.

What Inland Transportation Factors Affect Total Costs?

The ocean freight journey represents only part of the total transportation equation. Inland movement costs frequently determine the ultimate economic advantage.

How Do Inland Freight Costs Influence the Decision?

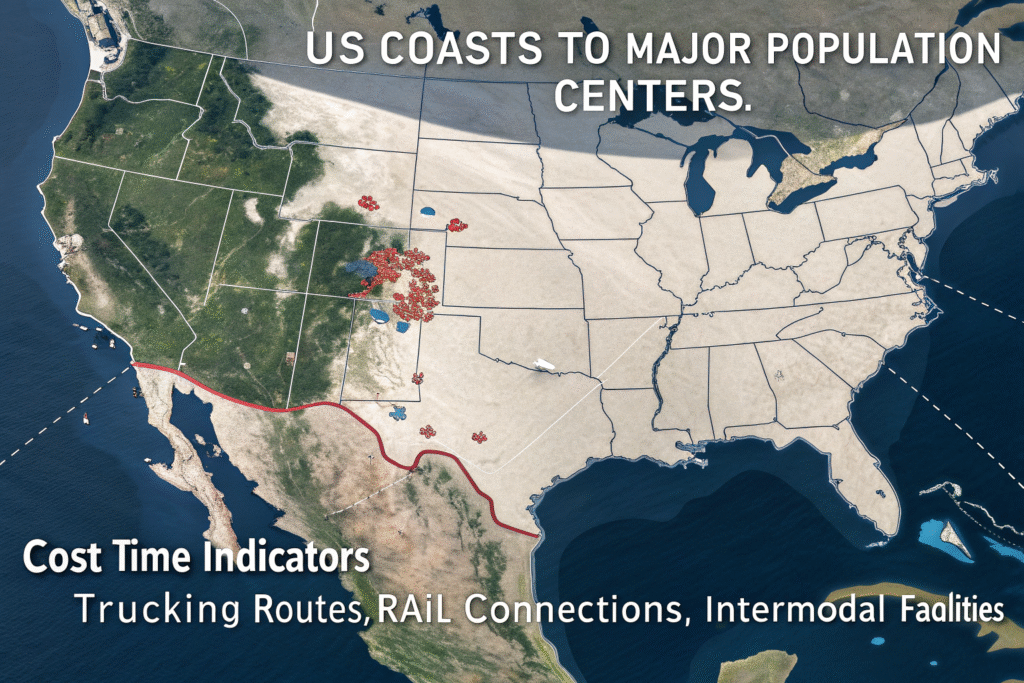

For destinations west of the Mississippi, West Coast ports typically offer $800-$1,500 lower inland transportation costs. The proximity to major consumption centers reduces both trucking expenses and transit times.

East Coast destinations within 300 miles of ports benefit from lower drayage costs but face challenges serving western markets. The cross-country trucking or rail costs often exceed the ocean freight savings from West Coast routing.

Population density patterns favor East Coast for serving the Boston-Washington corridor, while West Coast excels for California, Pacific Northwest, and Southwest markets. The "sweet spot" for each coast extends approximately 1,500 miles inland.

What Are the Intermodal Considerations?

Rail infrastructure from West Coast ports efficiently serves Midwest markets like Chicago, Dallas, and Memphis. The double-stack container trains provide cost-effective transportation 1,500-2,000 miles inland.

East Coast rail connections face more congestion and higher costs, particularly north-south routes along the I-95 corridor. The intermodal economics favor West Coast for destinations as far east as Chicago and Atlanta.

Trucking capacity varies regionally, with West Coast experiencing tighter capacity and higher rates during peak seasons. East Coast trucking markets are more fragmented but face similar driver shortage challenges.

How Should You Choose Based on Your Business Needs?

The optimal routing decision depends on your specific product characteristics, customer location, inventory strategy, and service requirements.

What Product Characteristics Favor Each Routing?

High-value, time-sensitive products often justify East Coast routing despite higher costs. The reduced in-transit inventory carrying costs and faster access to eastern markets can offset transportation premiums.

Bulky, low-value commodities typically benefit from West Coast routing to minimize transportation expenses. The ocean freight savings directly impact profit margins for price-sensitive products.

Perishable goods require careful analysis of total transit time versus cost. West Coast routing provides faster ocean transit but may require expedited inland transportation to reach eastern markets within shelf-life constraints.

How Does Customer Location Distribution Affect the Decision?

Businesses with 70%+ customers east of the Mississippi should strongly consider East Coast routing. The inland transportation savings and faster delivery times typically justify higher ocean freight costs.

Companies serving national markets often split shipments between coasts to optimize regional service levels. The 60/40 West/East split commonly provides the best balance of cost and service for distributed customer bases.

E-commerce businesses facing Amazon-like delivery expectations may need regional distribution centers fed by both coasts. The inventory duplication costs must be weighed against transportation savings and service benefits.

Conclusion

The West Coast versus East Coast decision requires analyzing your total landed costs, not just ocean freight rates. The most successful importers develop dynamic routing strategies that adapt to changing market conditions, capacity availability, and customer requirements.

At GeeseCargo, we've helped hundreds of clients implement coast selection strategies that reduced their total supply chain costs by 15-25% while improving service levels. The key is maintaining flexibility—using both coasts strategically based on seasonal patterns, capacity constraints, and inventory positioning needs.

Remember that the optimal choice today may change tomorrow as shipping lines adjust their networks, port conditions evolve, and your business requirements shift. Regular review of your routing decisions ensures you continue capturing the best combination of cost, speed, and reliability for your specific supply chain needs.