The recent 50% US tariff hike on Indian goods is shifting global sourcing strategies fast. For US importers of apparel, accessories, and gift products, India’s cost advantage is rapidly eroding—not just because of higher duties, but also slower port processing and supply chain uncertainty.

China now offers an alternative not just in manufacturing, but in diversified freight options—combining rail and ocean routes for greater flexibility, cost control, and predictability.

At GeeseCargo, we’ve been advising clients on when and how to use rail-ocean solutions to optimize cost and timelines for US-bound shipments. Here’s what’s changing, and how to leverage it.

Why Is India Losing Its Cost Edge?

India’s rising tariffs are just one problem. Many importers are also reporting:

- Longer lead times due to port congestion

- Higher inspection rates post-tariff

- Inconsistent documentation causing customs holds

Even if factory prices remain attractive, the total landed cost from India is now often higher than from China.

Real Cost Comparison: India vs. China (Post-Tariff)

| Product | India (Post-Tariff) | China (Ocean DDP) | Cost Advantage |

|---|---|---|---|

| Cotton Hoodie | $7.10 | $5.85 | $1.25 |

| PU Belt | $3.40 | $2.65 | $0.75 |

| Gift Packaging | $1.20 | $0.98 | $0.22 |

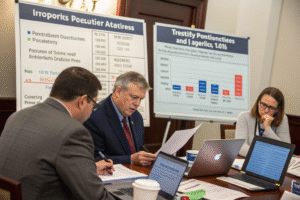

Reference: US Tariff Rates

Why China Is Ready to Absorb the Volume

- More export-ready ports (Ningbo, Shenzhen, Qingdao)

- Rail-ocean intermodal capacity for flexible routing

- Experienced freight forwarders with US customs expertise

What Are China-US Rail & Ocean Combo Routes?

A rail-ocean combo route moves goods from inland China to major ports via freight rail, then ships them to the US. It’s especially useful when factories are far from the coast, or when port congestion threatens schedules.

This method can cut inland trucking costs by up to 20% and reduce carbon footprint, while still hitting target ETAs.

Key Advantages

- Cost efficiency for inland provinces like Henan, Sichuan

- Stable schedules as rail avoids highway traffic delays

- Port flexibility—redirect to less congested export hubs

Check China Railway Express for cargo route insights.

Common Misconceptions

Some importers believe rail is only for Europe. In fact, China’s domestic rail network feeds both Pacific and Atlantic shipping lanes, ensuring smooth integration with US-bound ocean freight.

How Do Rail-Ocean Routes Compare to Pure Ocean Freight?

While ocean-only shipping is standard for most coastal factories, inland producers often face extra trucking miles and costs. Rail-ocean integration can improve both metrics.

For certain cargo types, it also reduces handling damage—important for apparel and gift packaging.

Cost & Time Overview

| Mode | Avg. Inland Cost | Port-to-US Transit | Best For |

|---|---|---|---|

| Truck + Ocean | High (fuel-heavy) | 18–30 days | Coastal or near-coast loads |

| Rail + Ocean | Lower (bulk rail) | 18–32 days | Inland factory shipments |

Rail legs can also avoid peak highway traffic, lowering risk of missed ETDs.

Explore Freightos rate data for updated ocean cost trends.

When Rail-Ocean Saves Most

- Large, heavy loads where trucking is fuel-cost heavy

- Multiple inland suppliers consolidating cargo

- Time-sensitive but not urgent (avoids air freight cost)

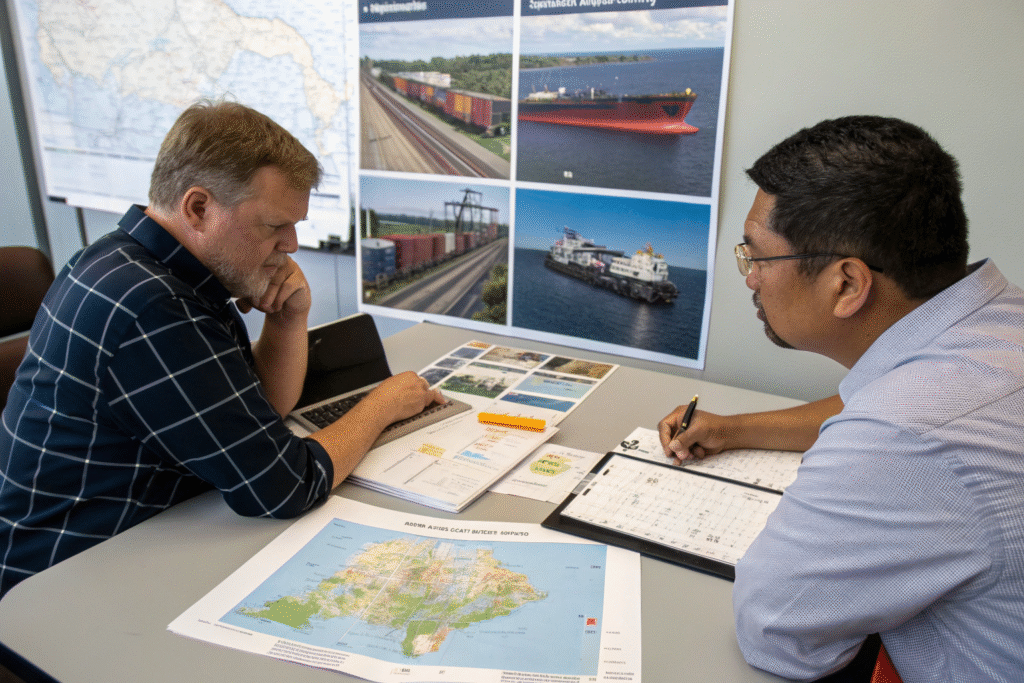

How Does DDP Fit Into Rail-Ocean Strategies?

![]()

Combining DDP with rail-ocean freight gives you both routing flexibility and cost certainty.

Your forwarder handles all duties, customs, and delivery, so tariffs or route changes don’t hit your landed cost.

Benefits for US Importers

- Locked pricing even if inland fuel or port charges rise

- Fewer customs errors due to centralized control

- Direct delivery to US warehouses or Amazon FBA

More about DDP benefits.

Example: Apparel Brand Case Study

A US brand sourcing from Chengdu switched from truck-ocean FOB to rail-ocean DDP:

- Saved $2,400 on inland transport

- Reduced damage claims by 15%

- Delivered to LA warehouse 2 days earlier than forecast

How to Choose Between Rail-Ocean and Pure Ocean Routes

The decision depends on your factory location, shipment size, and urgency.

If your suppliers are inland and you ship high volumes, rail-ocean DDP could be the sweet spot for cost control without time loss.

Our Recommendation Process

- Map supplier locations to rail hubs

- Compare inland trucking vs. rail costs

- Check port congestion forecasts

- Run DDP all-in price for each option

We’ll prepare a side-by-side report so you can choose confidently.

Conclusion

India’s cost competitiveness is waning for US importers, and China’s logistics flexibility is stepping up to fill the gap. By using rail-ocean freight—especially under DDP terms—you can keep costs predictable, avoid inland delays, and ship reliably into the US.

Ready to explore whether rail-ocean or pure ocean fits your next shipment? Email Ben Zhu at benzhu@geesecargo.com for a free lane analysis and DDP quote.