When we implemented our first automated storage system at GeeseCargo five years ago, I was skeptical about the return on investment. Today, that same system handles 300% more volume with 40% lower operational costs. The revolution in warehouse automation isn't coming—it's already here, and it's fundamentally changing how businesses approach storage economics.

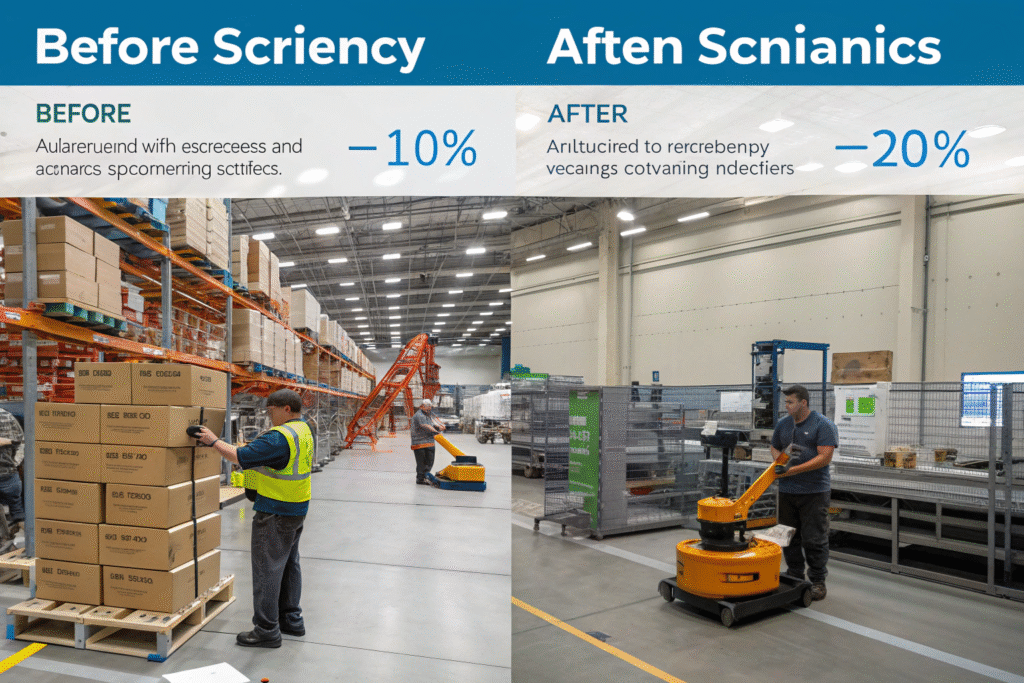

Warehouse automation typically reduces storage costs by 25-40% through labor optimization, space utilization improvements, and error reduction. However, these savings come with substantial upfront investment and require specific operational scales to achieve profitability. The breakeven point usually occurs between 18-36 months for most small to medium importers.

The automation landscape has evolved from simple conveyor systems to sophisticated robotics, AI-driven management, and fully automated retrieval systems. Understanding how these technologies impact your specific operation is crucial for making informed investment decisions. Let's examine the real cost implications of warehouse automation.

What Types of Automation Deliver the Best ROI?

Not all automation technologies provide equal returns. The most cost-effective solutions typically address specific operational bottlenecks rather than attempting full automation immediately.

How Do Basic Automation Systems Reduce Costs?

Goods-to-person systems represent the most accessible entry point for automation. These systems bring inventory to workers rather than requiring movement through aisles. The typical implementation reduces walking time by 70% and increases picking efficiency by 3-4 times.

Automated sorting systems process 2,000-10,000 items per hour with 99.9% accuracy. Manual sorting typically achieves 150-300 items hourly with higher error rates. The labor savings alone often justify the investment for operations handling more than 5,000 daily shipments.

Barcode and RFID automation eliminates manual scanning and data entry. The technology reduces receiving and shipping processing time by 60-80% while virtually eliminating mis-shipments and inventory inaccuracies. These systems typically pay for themselves within 12-18 months.

What Advanced Systems Provide Long-Term Savings?

Automated storage and retrieval systems (AS/RS) increase storage density by 30-40% compared to traditional shelving. The vertical utilization of cube space significantly reduces the warehouse footprint required for the same inventory volume.

Robotic picking systems operate 24/7 without fatigue, processing orders during off-peak hours when labor costs would be prohibitive. The systems achieve 99.95% accuracy rates, virtually eliminating picking errors and associated costs.

AI-driven warehouse management systems optimize inventory placement based on velocity, seasonality, and product affinity. The systems reduce travel time for high-volume items by 40-60% and improve space utilization through dynamic slotting algorithms.

How Does Automation Impact Labor Costs and Efficiency?

Labor represents 50-65% of traditional warehouse operating costs. Automation transforms this cost structure but requires different workforce management approaches.

What Is the Real Impact on Workforce Requirements?

Fully automated facilities typically operate with 30-50% fewer direct labor hours than manual operations. However, the remaining workforce requires different skills and commands higher wages. The net labor cost reduction typically ranges from 25-35%.

Shift patterns change dramatically with automation. Automated systems can operate efficiently with 2-3 shifts using minimal supervision, while manual operations require full staffing across all shifts. This flexibility reduces overtime costs and shift differential expenses.

Training requirements increase initially but decrease long-term. Automated systems require more sophisticated operation and maintenance skills, but these skills transfer more easily than manual process knowledge. Workforce turnover typically decreases by 40-60% in automated environments.

How Does Error Reduction Impact Overall Costs?

Picking accuracy improvements from 97% to 99.9% may seem small but have massive financial implications. For an operation shipping 10,000 orders monthly, this represents 290 fewer errors monthly, saving approximately $14,500 in return processing and customer service costs.

Inventory accuracy improvements from 92% to 99.8% reduce safety stock requirements by 15-25%. The capital tied up in buffer inventory can be redirected to growth initiatives or yield interest savings.

Damage reduction through automated handling typically ranges from 60-80%. Automated systems don't get tired, distracted, or handle packages carelessly. The savings in product replacement and customer compensation often justify automation independently.

How Does Space Utilization Change with Automation?

Traditional warehouses utilize 20-25% of their available cube space effectively. Automation dramatically improves this metric, directly impacting storage costs per square foot.

What Storage Density Improvements Can You Expect?

Vertical lift modules utilize the full building height, typically achieving 60-80% cube utilization compared to 20-25% with traditional shelving. The systems require only 20% of the floor space for the same storage capacity, potentially reducing facility size requirements.

Narrow aisle systems reduce aisle width from 10-12 feet to 5-6 feet, increasing storage capacity by 30-40% within the same footprint. The systems require specialized equipment but deliver rapid returns through better space utilization.

Automated high-density storage systems eliminate access aisles entirely for slow-moving inventory. The systems achieve 85-90% cube utilization by storing products densely and retrieving them through automated mechanisms. This approach works exceptionally well for seasonal items or buffer stock.

How Does Automation Impact Facility Requirements?

Automated facilities can operate effectively in spaces with lower clear heights than traditional warehouses. The precise control of automated systems allows for tighter tolerances, potentially opening more real estate options at lower rental rates.

Location flexibility increases as automation reduces labor dependency. Facilities can be situated in areas with lower labor costs while maintaining operational efficiency. The transportation savings to population centers often offset any increased automation costs.

Building specifications change with automation. Requirements for floor flatness, column spacing, and power distribution become more critical but enable more efficient space utilization. These specifications typically add 5-10% to construction costs but deliver 25-40% operational savings.

What Are the Hidden Costs and Considerations?

While automation delivers significant savings, the implementation carries costs and challenges that must be factored into decision-making.

What Implementation Challenges Affect Total Costs?

System integration typically represents 20-30% of total automation costs. Connecting automated systems with existing warehouse management, enterprise resource planning, and order management systems requires significant technical expertise.

Change management and training costs often surprise first-time automation implementers. Workforce resistance, process redesign, and skill development require dedicated resources and typically account for 10-15% of total project costs.

Business disruption during implementation causes temporary productivity declines of 20-40%. Proper planning can minimize this impact, but most operations experience at least 2-4 weeks of significant disruption during system commissioning and testing.

What Ongoing Costs Should You Anticipate?

Maintenance contracts for automated systems typically cost 8-12% of the system value annually. Unlike manual equipment, automated systems require specialized technicians and proprietary parts, creating dependency on specific service providers.

Software licensing and updates represent recurring costs that many businesses underestimate. Annual fees typically range from 15-20% of the initial software investment, with major version upgrades costing 40-60% every 3-5 years.

Energy consumption increases significantly with automation. Fully automated facilities typically consume 2-3 times more electricity than manual operations, though this is often offset by reduced heating, cooling, and lighting requirements in smaller spaces.

Conclusion

Warehouse automation presents a compelling economic case for businesses handling sufficient volume to justify the investment. The most successful implementations start with thorough analysis of current operations, clear identification of pain points, and realistic expectations about costs and benefits.

At GeeseCargo, we've guided hundreds of clients through automation decisions. The businesses that achieve the best results approach automation as a strategic investment rather than a simple cost reduction tool. They understand that the benefits extend beyond direct savings to include improved customer service, scalability, and competitive advantage.

Before pursuing automation, conduct a detailed analysis of your current costs, growth projections, and operational challenges. The technology should solve specific business problems rather than being implemented for its own sake. When properly planned and executed, warehouse automation transforms your storage economics and positions your business for sustainable growth.