When the Port of Los Angeles implemented their digital port community system, one of our clients reduced their average container dwell time from 5.2 days to 1.8 days—saving over $28,000 in demurrage charges in a single quarter. As founder of GeeseCargo with extensive experience in port operations, I've witnessed how digital transformation is fundamentally reshaping maritime logistics. Port digitalization isn't just about technology upgrades; it's about reengineering entire supply chain processes for speed and predictability.

Port digitalization accelerates shipments through paperless processing, real-time visibility, predictive analytics, and automated coordination between supply chain partners. Digital ports typically reduce vessel wait times by 40-60%, cut container dwell times by 50-70%, and decrease documentation processing from days to hours. The cumulative effect typically shaves 3-8 days off total transit times for China-US shipments.

The digital revolution in port operations addresses the traditional bottlenecks that have plagued shipping for decades. By replacing manual processes, information silos, and sequential operations with integrated digital systems, ports are transforming from congestion points to efficiency engines.

What Specific Digital Technologies Drive Speed Improvements?

Multiple technologies work together to create cumulative time savings throughout the port call process.

How Do Port Community Systems Accelerate Information Flow?

Single window platforms eliminate redundant documentation. Instead of submitting separate documents to customs, terminals, carriers, and other authorities, digital ports allow single submission that automatically distributes to all required parties.

Real-time status updates prevent waiting for information. All stakeholders see the same real-time data about vessel positions, container status, and terminal operations, enabling proactive planning rather than reactive response.

Automated validations catch errors before they cause delays. Digital systems flag incomplete or inconsistent information immediately, allowing correction before vessels arrive rather than after problems occur.

What Role Do Terminal Operating Systems Play in Speed Enhancement?

Equipment optimization algorithms reduce vessel working time. Advanced TOS platforms calculate optimal crane assignments, container sequencing, and equipment deployment to minimize vessel port stays.

Yard management automation speeds container locating and retrieval. Digital systems track exact container locations and calculate optimal movement paths, reducing container retrieval time from hours to minutes.

Gate automation dramatically cuts truck processing time. Automated gate systems using OCR, RFID, and appointment scheduling process trucks in 2-3 minutes instead of 20-30 minutes with manual checks.

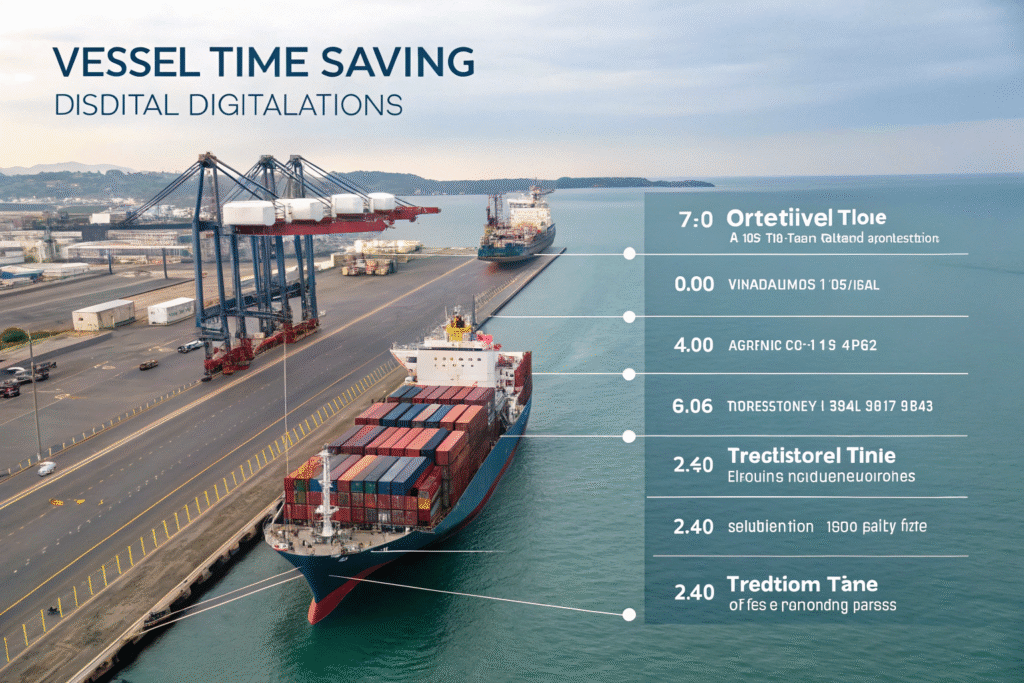

How Does Digitalization Reduce Vessel Port Time?

Vessel port time represents one of the most significant opportunities for digital speed improvements.

How Does Pre-arrival Digital Coordination Help?

Just-in-time arrival optimization reduces anchorage waiting. Digital systems coordinate vessel speeds to arrive precisely when berths and labor are available, eliminating days of waiting at anchor for berth availability.

Advanced cargo documentation enables immediate operations. With all documentation submitted and approved before vessel arrival, cargo operations can begin immediately upon berthing rather than waiting for paperwork processing.

Staged labor and equipment planning ensures immediate resource availability. Digital systems schedule labor, equipment, and terminal resources based on precise vessel arrival times and cargo profiles.

What Operational Efficiencies Reduce Working Time?

Dynamic stowage planning optimizes cargo operations. Digital tools calculate optimal container discharge and loading sequences to minimize crane moves and vessel stability adjustments.

Real-time performance monitoring identifies and resolves bottlenecks. Operations managers can see equipment productivity, identify developing issues, and redeploy resources before delays accumulate.

Automated documentation generation speeds completion processes. Digital systems automatically generate departure documents, customs declarations, and other required paperwork as operations conclude.

How Does Digitalization Accelerate Landside Operations?

The speed benefits extend beyond vessel operations to the critical landside container movement processes.

How Do Digital Gate Systems Speed Truck Processing?

Appointment scheduling eliminates gate congestion. Digital systems spread truck arrivals evenly throughout the day, preventing morning rushes and afternoon lulls that characterized traditional first-come, first-served operations.

Automated check-in reduces processing time from 45 minutes to 2-3 minutes. OCR systems reading container numbers, chassis information, and license plates automatically process most transactions without human intervention.

Paperless instructions eliminate document handling delays. Drivers receive digital instructions and updates rather than waiting for paperwork processing and physical document exchange.

How Does Yard Digitalization Speed Container Retrieval?

Real-time location tracking eliminates container searching. Instead of teams physically searching yards for containers, digital systems provide exact locations, reducing retrieval time by 60-80%.

Optimal movement planning calculates most efficient retrieval sequences. Systems analyze container positions, equipment availability, and truck appointments to sequence movements for minimum time and maximum equipment utilization.

Automated equipment coordination prevents waiting for resources. The system dispatches yard equipment precisely when needed rather than relying on manual coordination and radio communication.

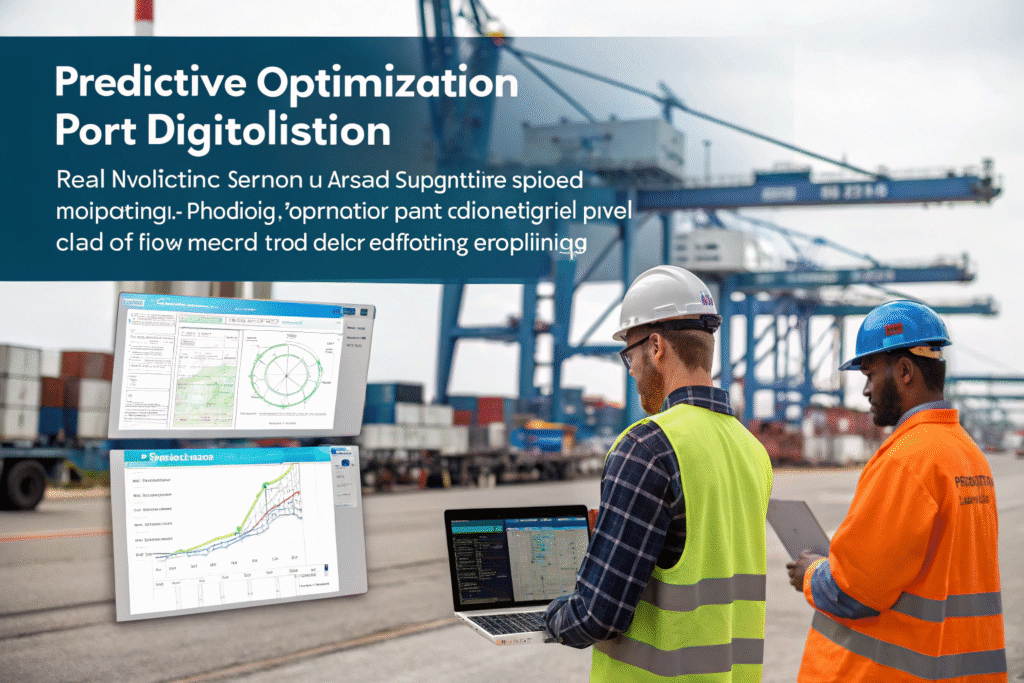

How Does Data Visibility Enable Predictive Speed Optimization?

The real power of digitalization comes from using data not just to react faster, but to predict and prevent delays before they occur.

How Does Predictive Analytics Prevent Delays?

Congestion forecasting enables proactive resource allocation. By analyzing historical patterns, weather data, and current volumes, systems predict congestion points and pre-position equipment and labor.

Vessel arrival prediction improves berth planning. Advanced ETA algorithms incorporating weather, current, and performance data provide more accurate arrival times than traditional position reporting.

Equipment maintenance prediction prevents breakdown delays. IoT sensors and usage analytics predict equipment failures before they occur, enabling maintenance during planned downtime rather than emergency repairs during operations.

How Does Machine Learning Optimize Operations?

Pattern recognition identifies invisible inefficiencies. ML algorithms analyze thousands of operations to identify subtle patterns and relationships that human planners cannot detect.

Continuous optimization adapts to changing conditions. Unlike static processes, ML systems continuously refine operations based on actual performance and changing conditions.

Anomaly detection flags emerging issues immediately. Systems automatically detect operations falling outside normal parameters, enabling intervention before small issues become major delays.

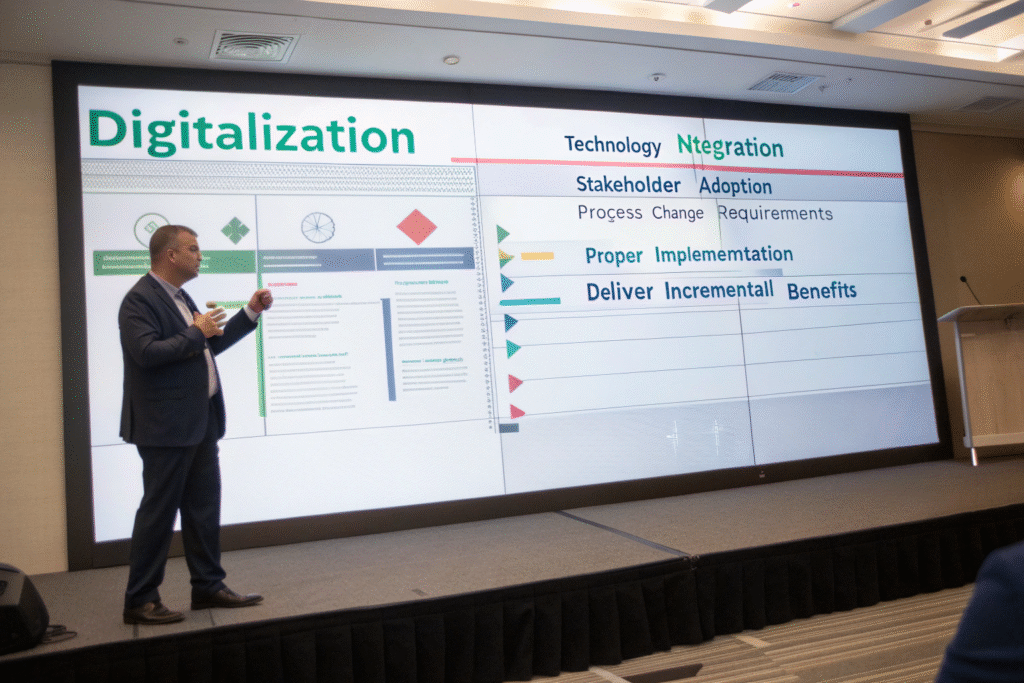

What Are the Implementation Challenges and Timelines?

While benefits are significant, digital transformation requires careful planning and staged implementation.

What Technical Challenges Must Be Overcome?

Legacy system integration creates compatibility challenges. Many ports operate decades-old systems that must be integrated with modern digital platforms, requiring careful interface development.

Data standardization enables system interoperability. Different stakeholders use different data formats and standards, requiring alignment for seamless digital handoffs.

Cybersecurity requirements add complexity. Digital systems handling sensitive commercial and operational data require robust security measures that can slow implementation.

How Long Does Meaningful Digitalization Take?

Basic digitalization delivering 20-30% time savings typically requires 12-18 months. This includes core systems like port community platforms, terminal operating systems, and basic automation.

Advanced digitalization achieving 40-60% time savings generally takes 2-3 years. This incorporates IoT, predictive analytics, and deeper process integration across stakeholders.

Full digital transformation reaching 60-80% improvements may require 3-5 years. This includes AI/ML implementation, complete ecosystem integration, and cultural transformation.

How Can Shippers Maximize Digitalization Benefits?

Shippers can take specific actions to leverage port digitalization for maximum speed improvements.

What Preparation Accelerates Digital Benefits?

System integration with port digital platforms enables automated data exchange. Connecting your ERP, TMS, or logistics platforms to port community systems prevents manual data entry and delays.

Documentation digitization and standardization ensures smooth processing. Having all required documents in digital formats with standardized data elements enables seamless submission and validation.

Staff training on digital processes prevents workflow bottlenecks. Ensuring your team understands how to use digital systems and processes maximizes the speed benefits they enable.

What Operational Changes Maximize Time Savings?

Proactive submission of digital documentation before vessel arrival. Submitting all required documents through digital channels days before vessel arrival enables immediate operations upon berthing.

Utilization of real-time visibility for exception management. Monitoring digital port systems for potential issues enables proactive intervention before delays impact your shipments.

Adoption of digital appointment scheduling and instructions. Using fully digital processes for trucking, rail, and other intermodal connections prevents manual processing delays.

Conclusion

Port digitalization represents the most significant advancement in maritime logistics efficiency in decades, offering substantial time savings that directly impact supply chain performance and costs. The most forward-thinking shippers are already positioning themselves to maximize these benefits through system integration, process adaptation, and strategic partnerships with digitally advanced ports and carriers.

At GeeseCargo, we've helped clients reduce port-related delays by 55-70% through strategic leveraging of port digitalization initiatives. The key is recognizing that digitalization benefits aren't automatic—they require shippers to adapt their processes, integrate their systems, and actively participate in digital ecosystems.

Begin your digitalization journey by identifying which of your trading partners offer the most advanced digital capabilities, then systematically integrate with their systems and adapt your processes to leverage the available digital tools. Remember that in the era of port digitalization, the fastest shipments aren't necessarily those on the newest vessels, but those moving through the most digitally advanced supply chains.