Many businesses shipping from China struggle with the economics of partial container loads or small air freight shipments. The per-unit costs can be prohibitive, eating into profit margins and making international trade challenging. Shipment consolidation promises significant savings, but businesses rightly wonder if the operational complexity delivers meaningful financial benefits.

Shipment consolidation can save businesses 25-60% on shipping costs compared to individual small shipments. For LCL ocean freight, savings typically range from 30-50%, while air consolidation saves 40-60% compared to standard air cargo rates. These percentages translate to thousands of dollars monthly for regular shippers, with additional hidden savings in reduced administrative costs and improved operational efficiency.

Let's examine the specific savings across different shipping scenarios and how consolidation transforms your cost structure beyond simple freight rate reductions.

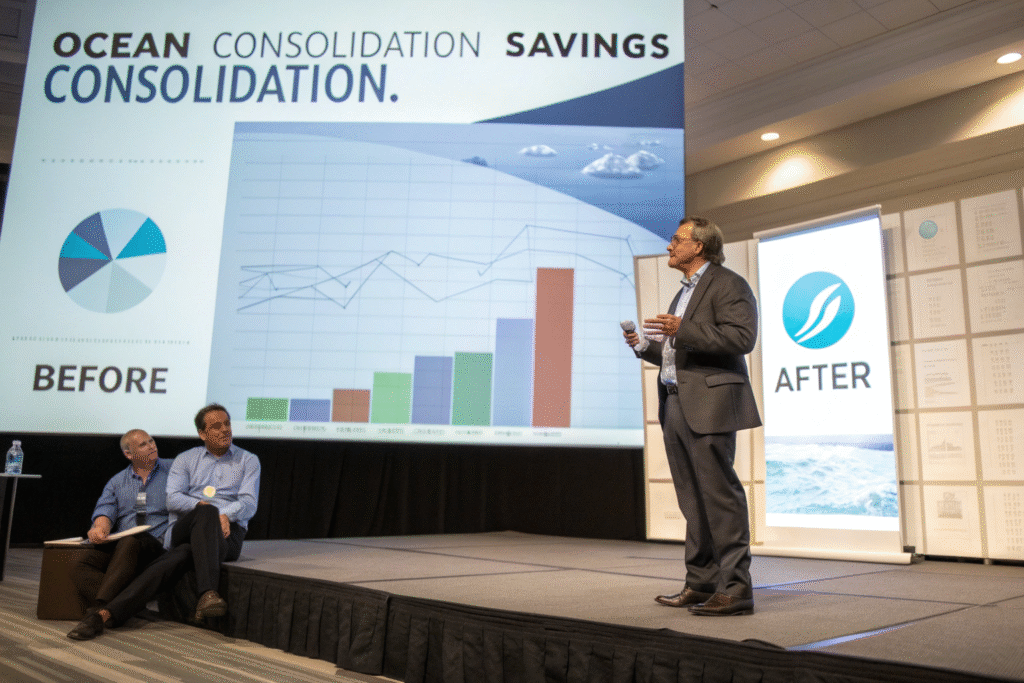

How do ocean freight consolidation savings break down?

Ocean freight consolidation creates economies of scale that dramatically reduce per-unit costs for businesses that don't generate full container volumes. The savings come from spreading fixed costs across multiple shippers and optimizing container space utilization.

For Less than Container Load shipments, consolidation typically saves 30-50% compared to booking individual LCL shipments. A standard 2 CBM shipment that might cost $800-1,200 as a standalone LCL shipment could cost $400-700 when consolidated with other cargo. The savings increase with volume—a 10 CBM shipment might see 40-55% savings. These percentages translate to absolute savings of $300-800 per shipment depending on origin, destination, and current market rates. The savings come from reduced terminal handling charges, lower per-CBM freight rates, and optimized documentation processes.

What specific cost elements decrease through consolidation?

Key areas of savings include:

- Basic ocean freight charges reduced through volume-based pricing

- Terminal handling charges spread across multiple shipments

- Documentation fees consolidated into single processing

- Customs clearance costs handled more efficiently for grouped shipments

- Fuel surcharges calculated at more favorable rates

- Administrative overhead reduced through single shipment management

These combined reductions create the significant overall savings.

How does shipment size affect savings percentage?

Savings typically increase with volume:

- 1-3 CBM: 25-35% savings versus individual LCL

- 4-7 CBM: 35-45% savings through better space utilization

- 8-12 CBM: 45-55% savings approaching FCL economics

- 13-15 CBM: Often better to upgrade to 20' FCL container

- Multiple shipments: Additional savings through coordinated scheduling

Understanding these thresholds helps maximize your consolidation benefits.

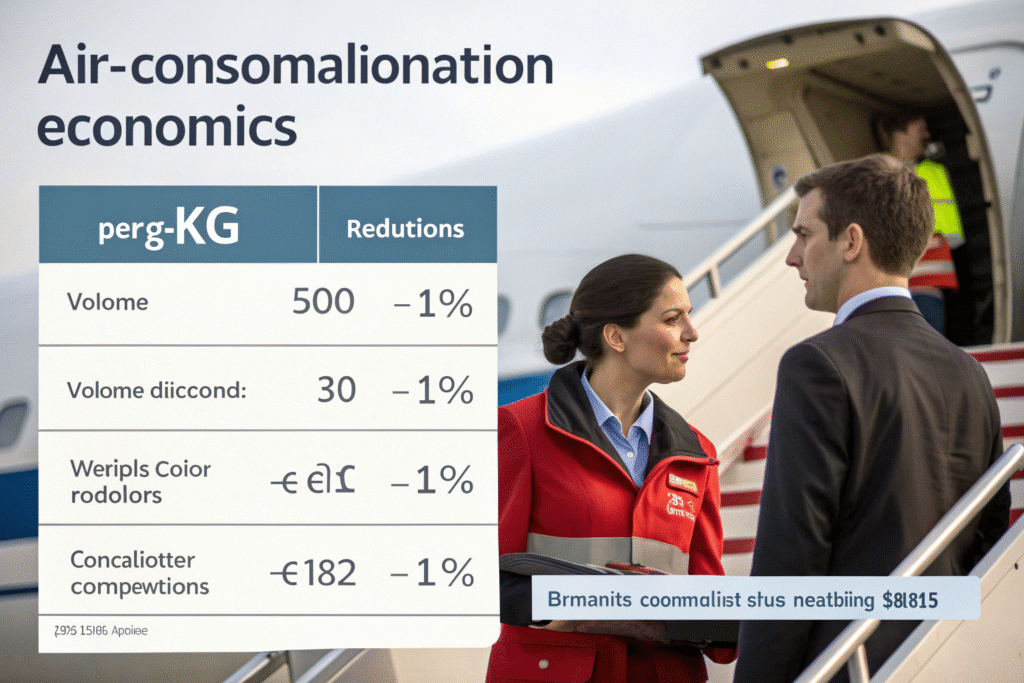

What air freight consolidation savings can you expect?

Air consolidation delivers even more dramatic percentage savings than ocean options because air freight rates have steeper volume discounts and higher fixed cost components. The per-kg rate reductions can transform air shipping from a luxury to a viable regular option.

Air consolidation typically saves 40-60% compared to standard air cargo rates for shipments under 500 kg. A 100 kg shipment that might cost $1,200-1,800 as a standalone air shipment could cost $600-900 when consolidated. For larger shipments of 300-500 kg, savings often reach 50-65% due to better weight break pricing. These savings make air freight economically viable for more shipments, potentially reducing inventory carrying costs and enabling faster response to market opportunities.

How do air freight weight breaks amplify savings?

Air consolidation leverages critical weight breaks:

- 45 kg shipments achieve rates typically reserved for 100+ kg

- 100 kg consolidated qualifies for 300+ kg rate levels

- 300 kg grouped accesses 500+ kg pricing tiers

- 500 kg combined reaches 1,000+ kg rate categories

- 1,000 kg consolidated matches freighter aircraft rates

These weight break advancements create the dramatic per-kg cost reductions.

What additional air-specific savings occur?

Beyond basic freight charges:

- Security screening fees reduced through batch processing

- Terminal handling charges spread across multiple shipments

- Documentation processing streamlined for consolidated manifests

- Customs brokerage more efficient for grouped declarations

- Fuel surcharges calculated at more favorable percentages

These additional savings further improve air consolidation economics.

What hidden savings and benefits does consolidation provide?

Beyond the visible freight charge reductions, consolidation delivers significant hidden savings that often equal or exceed the direct transportation cost benefits. These additional advantages impact your overall business efficiency and competitiveness.

Administrative cost savings typically amount to 15-25% of your logistics management expenses through reduced documentation, single payment processing, and streamlined communication. Inventory carrying cost reductions of 10-20% occur through more consistent transit times and reduced safety stock requirements. Damage and loss reductions of 5-15% happen through better packaging, handling, and tracking of consolidated shipments. These combined hidden savings can add another 30-60% to your visible freight cost reductions.

How does consolidation reduce administrative costs?

Administrative efficiencies include:

- Single documentation set instead of multiple shipments

- One customs filing rather than individual declarations

- Unified payment processing simplifying accounting

- Consolidated communication with single point of contact

- Reduced error correction through standardized processes

These efficiencies save both time and money in logistics management.

What inventory benefits does consolidation create?

Supply chain improvements include:

- More predictable transit times reducing safety stock requirements

- Consistent scheduling enabling better production planning

- Reduced stockouts through reliable delivery patterns

- Lower working capital tied up in transit inventory

- Improved turnover through optimized shipment frequency

These inventory benefits significantly impact overall business financials.

How do you calculate your specific potential savings?

Accurate savings calculation requires analyzing your specific shipment patterns, product characteristics, and business operations. Generic percentages provide guidance, but precise figures come from detailed assessment of your unique situation.

Start by analyzing your last 6-12 months of shipping data: individual shipment volumes, frequencies, modes used, and total costs. Calculate your average cost per CBM for ocean or per kg for air across all shipments. Then work with consolidation providers to obtain quotes for handling the same volume through consolidated services. The difference represents your potential direct savings. Add estimated administrative time savings based on your internal cost rates. Finally, factor in potential inventory carrying cost reductions based on more consistent lead times.

What data do you need for accurate savings calculation?

Essential information includes:

- Shipment volumes in CBM or kg per shipment

- Shipping frequency and seasonal patterns

- Current freight rates across all modes used

- Accessorial charges and additional fees paid

- Administrative time spent per shipment

- Inventory levels maintained for variability

This data enables precise savings modeling rather than rough estimates.

How do you account for business-specific factors?

Important considerations include:

- Product value density affecting transportation cost sensitivity

- Customer service requirements influencing speed needs

- Seasonal fluctuations impacting consolidation availability

- Growth projections affecting future shipping volumes

- Competitive factors requiring specific service levels

These business context factors refine your savings calculations.

What are the potential drawbacks or limitations?

While consolidation offers significant savings, it's not universally optimal for all situations. Understanding the limitations and potential drawbacks ensures you make informed decisions about when consolidation makes sense for your business.

The primary trade-off involves extended transit times—consolidated shipments typically take 3-7 days longer than direct services due to the additional handling and coordination required. There's also reduced flexibility for last-minute changes once shipments enter the consolidation pipeline. Additionally, some businesses face challenges with product compatibility when goods with different characteristics or regulatory requirements are consolidated together. Understanding these limitations helps determine the right balance between consolidated and direct shipping for your specific needs.

When does consolidation not make financial sense?

Situations where direct shipping may be better:

- Extremely time-sensitive shipments requiring fastest possible transit

- High-value products where inventory costs outweigh transportation savings

- Unique handling requirements incompatible with standard consolidation

- Very small shipment volumes where savings don't justify complexity

- Unpredictable shipping patterns that don't allow consolidation planning

Recognizing these scenarios prevents inappropriate consolidation use.

How can you mitigate consolidation drawbacks?

Effective mitigation strategies include:

- Maintaining mixed shipping strategy using both consolidated and direct options

- Implementing buffer inventory to accommodate longer transit times

- Developing clear compatibility guidelines for consolidated products

- Establishing contingency plans for urgent shipments outside consolidation

- Building relationships with multiple providers for flexibility

These approaches allow enjoying consolidation benefits while managing limitations.

Conclusion

Shipment consolidation typically delivers 25-60% savings on transportation costs, with additional hidden benefits in reduced administrative expenses, lower inventory carrying costs, and decreased product damage. The exact savings depend on your specific shipment patterns, product characteristics, and business operations. For most small to medium businesses importing from China, consolidation represents one of the most effective strategies for reducing total landed costs while maintaining reliable supply chain operations. The key to maximizing benefits lies in accurate analysis of your specific situation, careful provider selection, and balanced implementation that acknowledges both the significant savings opportunities and the legitimate limitations of consolidated shipping.