When one of our clients had a $250,000 shipment of electronic devices rejected by airlines due to improper lithium battery documentation, I realized how many businesses underestimate these complex regulations. As founder of GeeseCargo with specialized experience in dangerous goods logistics, I've learned that shipping lithium batteries isn't just about compliance—it's about understanding the intricate classification, packaging, and documentation requirements that vary by mode and destination.

Shipping lithium batteries from China requires strict compliance with IATA DGR for air transport, IMDG Code for ocean transport, and specific carrier requirements. The process involves proper classification (UN3480, UN3481, UN3090, UN3091), specialized packaging, mandatory testing, and complete documentation. Non-compliance can result in rejected shipments, hefty fines ($50,000+ per violation), and even criminal liability.

Lithium battery shipping represents one of the most regulated areas in international logistics, with requirements that change frequently as safety standards evolve. Companies that master these requirements typically experience 90% fewer shipping delays and avoid the significant costs of compliance failures.

What Are the Critical Classification Requirements?

Proper classification forms the foundation of compliant lithium battery shipments, with specific UN numbers assigned to different battery types and configurations.

How Do You Distinguish Between Lithium-Ion and Lithium Metal Batteries?

Lithium-ion batteries (rechargeable) fall under UN3480 (packed with equipment) or UN3481 (contained in equipment). These are typically found in consumer electronics, power tools, and electric vehicles, with specific state-of-charge restrictions for transport.

Lithium metal batteries (non-rechargeable) are classified as UN3090 (packed with equipment) or UN3091 (contained in equipment). These are commonly used in watches, medical devices, and backup power systems, with different quantity limitations than lithium-ion.

Hybrid and damaged/defective batteries have special requirements. Recalled, damaged, or prototype batteries often fall under more restrictive shipping categories requiring additional approvals and packaging.

What State-of-Charge Restrictions Apply?

Air transport typically requires lithium-ion batteries to be at or below 30% state of charge. This reduces thermal runaway risk during pressure changes and temperature variations encountered during air transport.

Ocean transport may allow higher states of charge but with additional packaging requirements. While generally less restrictive, certain vessel types and routes may impose similar limitations to air transport.

Special permissions exist for fully charged batteries in specific circumstances. Some medical devices and critical equipment may ship at full charge with proper documentation and carrier approval.

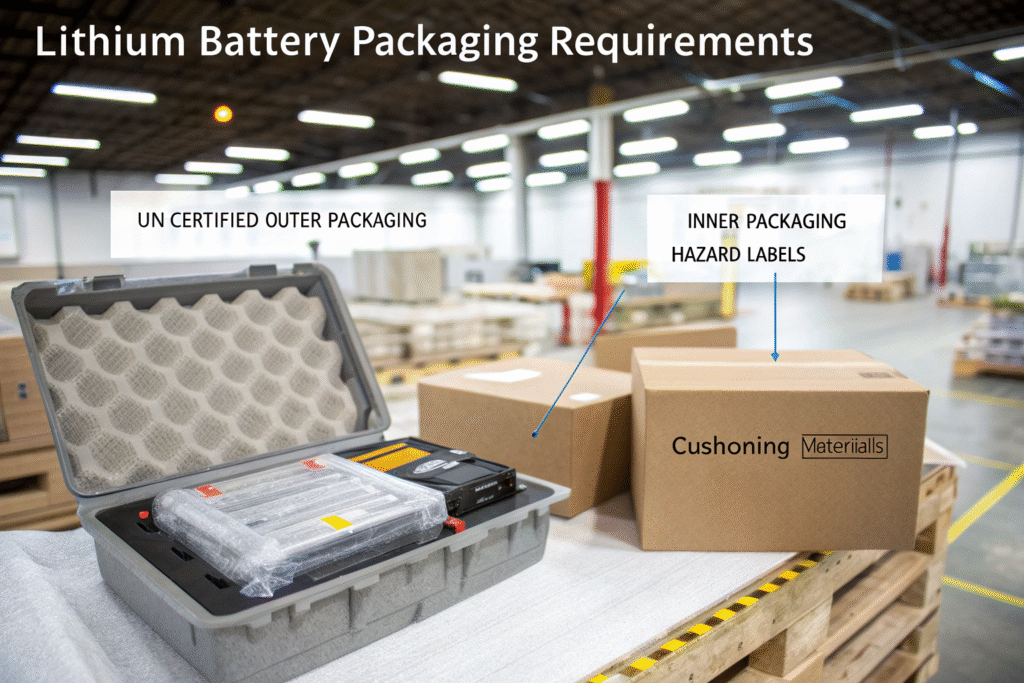

What Packaging Requirements Ensure Compliance?

Proper packaging represents the most visible aspect of lithium battery compliance, with specific performance-tested materials required.

What Constitutes UN-Certified Packaging?

Performance testing to UN38.3 standards is mandatory for all lithium battery shipments. This testing includes altitude simulation, thermal testing, vibration, shock, external short circuit, impact, overcharge, and forced discharge tests.

Specific packaging groups (I, II, or III) depend on battery chemistry and quantity. More hazardous batteries require more rigorous packaging (Group I), while common consumer batteries typically fall into Group II.

Marking and labeling requirements include specific Class 9 hazard labels. Packages must display lithium battery handling labels, Class 9 hazard labels, and proper shipping names with UN numbers.

What Are the Critical Inner Packaging Considerations?

Protection against short circuits is the most fundamental requirement. Terminals must be protected by recessing, covering with non-conductive caps, or using individual plastic bags.

Adequate cushioning prevents damage during normal transport conditions. Inner packaging must prevent movement within outer packaging and protect against crushing or impact.

Separation from other dangerous goods prevents interaction risks. Lithium batteries cannot be packed with other dangerous goods that might create thermal or chemical reactions.

What Documentation Is Absolutely Essential?

Complete and accurate documentation forms the backbone of compliant lithium battery shipments, with specific forms required for different transport modes.

What Is the Lithium Battery Test Summary Requirement?

The test summary must document successful completion of UN38.3 testing. This includes test laboratory information, battery specifications, test dates, and results for all required test components.

Manufacturer information must be clearly identified and traceable. The entity responsible for testing and manufacturing must be clearly documented for regulatory accountability.

Accessibility throughout the supply chain is mandatory. The test summary must accompany shipments and be available to all parties in the transport chain, including authorities.

How Does the Dangerous Goods Declaration Differ for Batteries?

Additional lithium battery information supplements the standard DGD. This includes the number of batteries, watt-hour ratings (for lithium-ion), lithium content (for lithium metal), and special provisions applied.

Emergency response information must be specific to lithium battery incidents. Unlike other dangerous goods, lithium battery fires require specific extinguishing agents and response procedures.

Carrier-specific variations require careful attention. Different airlines and ocean carriers may have additional documentation requirements beyond the regulatory minimums.

What Are the Key Differences Between Air and Ocean Transport?

Understanding modal differences prevents costly mistakes when choosing transportation methods for lithium battery shipments.

What Quantity Limitations Apply to Air Transport?

Passenger aircraft have stricter limitations than cargo aircraft. Smaller quantities and more restrictive packaging typically apply to passenger flights due to higher safety concerns.

Watt-hour and lithium content limits determine maximum quantities. Lithium-ion batteries are limited by watt-hour rating (typically 100Wh per cell, 20kg per package for Section II), while lithium metal batteries are limited by lithium content (2g per cell, 1kg per package for Section II).

State-of-charge restrictions are more stringent for air transport. The 30% state-of-charge limit for air transport doesn't typically apply to ocean shipments.

How Do Ocean Transport Requirements Differ?

Larger quantities are generally permitted in ocean transport. While still regulated, ocean vessels can typically accommodate larger lithium battery shipments than aircraft.

Different segregation requirements apply on vessels. Specific stowage locations away from heat sources and other reactive materials are required on vessels.

Container packing certifications may be required. Some carriers require specific certifications for containers carrying significant quantities of lithium batteries.

How Can You Verify Chinese Manufacturer Compliance?

Working with Chinese manufacturers requires additional due diligence to ensure regulatory compliance throughout the supply chain.

What Documentation Should You Require from Chinese Manufacturers?

UN38.3 test reports from accredited laboratories are non-negotiable. Verify that testing was conducted by ILAC-accredited laboratories with proper scope and recent dates.

Manufacturing quality control documentation demonstrates consistent production. Request evidence of production controls, material traceability, and batch testing procedures.

Transportation safety data specific to battery models should be available. Manufacturers should provide specific handling instructions, thermal characteristics, and safety data for each battery type.

How Can You Audit Manufacturer Compliance?

On-site inspections verify physical compliance with regulations. Visiting manufacturing facilities allows verification of storage conditions, production controls, and packaging processes.

Sample testing validates manufacturer claims. Independent testing of sample batteries confirms that production matches tested samples and continues to meet specifications.

Documentation review ensures complete regulatory compliance. Verify that all required documentation is properly completed, translated if necessary, and readily available.

What Are the Most Common Compliance Mistakes?

Understanding frequent errors helps businesses avoid costly shipping rejections and regulatory penalties.

What Documentation Errors Cause the Most Problems?

Incomplete or missing test summaries result in immediate rejections. The most common error is failing to include the required lithium battery test summary with shipments.

Incorrect dangerous goods declarations lead to enforcement actions. Misstating battery quantities, classifications, or proper shipping names creates significant compliance violations.

Outdated documentation fails to reflect regulatory changes. Using old forms or expired test reports violates current regulations, even if they were compliant when created.

What Packaging and Marking Mistakes Occur Frequently?

Using non-UN certified packaging for larger shipments. While excepted quantities have different rules, most commercial shipments require performance-tested packaging.

Inadequate terminal protection causes short circuit incidents. Exposed terminals during transport create fire risks and regulatory violations.

Missing or incorrect hazard labels trigger inspections and rejections. Proper lithium battery handling labels must be specific to the battery type and configuration.

Conclusion

Shipping lithium batteries from China requires meticulous attention to classification, packaging, documentation, and carrier requirements. The most successful shippers treat lithium battery compliance as an integrated business process rather than a last-minute logistics consideration, building compliance into their product design, manufacturing, and supply chain operations.

At GeeseCargo, we've helped clients achieve 99.6% compliance rates for lithium battery shipments through systematic processes that address both regulatory requirements and practical operational realities. The key is recognizing that lithium battery shipping isn't just about avoiding penalties—it's about ensuring safety throughout the global supply chain.

Begin your lithium battery shipping preparation by thoroughly understanding your specific battery classifications, then develop comprehensive processes for documentation, packaging, and carrier coordination. Remember that in lithium battery logistics, compliance isn't a cost center—it's an essential investment in supply chain reliability and brand protection.