When one of our clients needed to ship a 45-ton industrial generator from Shanghai to Houston, we discovered that standard container shipping simply wouldn't work. As founder of GeeseCargo with extensive project cargo experience, I've learned that heavy and oversized shipments require completely different approaches than standard containerized goods. These shipments demand specialized equipment, meticulous planning, and unique documentation.

Shipping heavy or project cargo from China requires specialized equipment like flat racks, open tops, or breakbulk vessels, plus detailed route surveys, custom securing plans, and specialized insurance. Project cargo typically costs 2-5 times more than container shipping and requires 3-6 months of advance planning for proper execution. Success depends on early supplier coordination, precise measurements, and experienced project forwarders.

Heavy and project cargo encompasses everything from machinery and industrial equipment to wind turbine blades and construction materials. These shipments share common challenges including weight restrictions, dimensional limitations, and complex handling requirements that standard logistics providers often cannot accommodate.

What Defines Heavy and Project Cargo?

Understanding the specific characteristics of your cargo determines the equipment, routing, and handling requirements.

What Are the Weight and Dimension Thresholds?

Standard container limits are typically 26-28 metric tons for 40-foot containers. Beyond these weights, you'll need specialized equipment like flat racks or platform containers that can handle 30-45 tons.

Dimensional limits for standard containers are approximately 2.35m width and 2.35m height. Cargo exceeding these dimensions requires open-top containers, flat racks, or breakbulk shipping with custom securing.

Project cargo often involves multiple pieces shipped together. Complex projects may include both containerized components and oversized pieces, requiring coordinated shipping and assembly planning.

What Equipment Options Handle Different Cargo Types?

Flat rack containers handle wide and heavy cargo. These containers have collapsible sides and can accommodate cargo up to 3.0m wide, with capacities of 30-45 tons depending on the specific equipment.

Open top containers accommodate tall cargo. With removable tarpaulin roofs, these containers can load cargo up to 2.7m high internally, or even taller if cargo extends above container height.

Platform containers and MGOs handle the heaviest loads. These flat platforms without sides can carry up to 45 tons and accommodate extremely wide or irregularly shaped cargo.

How Should You Plan Heavy Cargo Shipments?

Successful heavy cargo shipping requires meticulous planning far beyond standard container shipments.

What Advance Planning Is Essential?

Early equipment booking is crucial for specialized containers. Flat racks, open tops, and platform containers have limited availability and often require 4-8 weeks advance booking, especially during peak seasons.

Route surveys identify potential obstacles before shipping. Professional surveys assess bridge heights, road weights, turning radii, and overhead obstacles along the entire route from factory to final destination.

Engineering reviews ensure proper securing and handling. Structural engineers should review lifting points, securing methods, and weight distribution to prevent damage during transit.

How Do Documentation Requirements Differ?

Detailed packing lists must include exact dimensions and weights. Unlike standard cargo where approximate weights suffice, heavy cargo requires precise measurements for equipment selection and securing plans.

Specialized insurance coverage is essential for high-value project cargo. Standard cargo insurance often excludes heavy lifts, specialized handling, and project cargo, requiring specific project insurance policies.

Export licenses may be required for certain machinery or equipment. Some industrial equipment requires special export permits from Chinese authorities, particularly if it has potential military applications.

What Are the Key Shipping Method Options?

Different shipping methods suit different types of heavy and project cargo based on urgency, cost, and technical requirements.

When Should You Choose Breakbulk Shipping?

Oversized cargo exceeding container dimensions requires breakbulk. Cargo too large for even the largest flat racks must ship as breakbulk, loaded directly into vessel holds using cranes.

Multiple large pieces moving together benefit from breakbulk consolidation. Projects involving several oversized components can be consolidated on a single vessel, though this requires careful scheduling.

Heavy lifts beyond container capacity need breakbulk solutions. While the largest flat racks handle ~45 tons, breakbulk vessels can accommodate individual pieces weighing hundreds of tons.

What Are Roll-on/Roll-off (Ro-Ro) Advantages?

Self-propelled equipment ships efficiently via Ro-Ro. Machinery that can move under its own power, like construction equipment or vehicles, can drive directly onto specialized vessels.

Reduced handling minimizes damage risk. Since cargo isn't lifted by cranes, Ro-Ro shipping reduces potential for damage from improper lifting or securing.

Faster port turnaround reduces costs. Ro-Ro vessels typically have quicker port operations than breakbulk or container vessels, potentially reducing port charges.

How Do You Manage Inland Transportation?

Moving heavy cargo within China and to destination locations presents unique challenges beyond ocean transport.

What Are the Chinese Domestic Transport Considerations?

Chinese road regulations vary by province and vehicle type. Different provinces have different weight limits, height restrictions, and permit requirements for oversized transport.

Factory access may require specialized equipment. Some factories have limited access roads or loading areas that cannot accommodate standard heavy transport equipment.

Police escorts are often required for oversized shipments. In China, oversized transport typically requires police escort vehicles, sometimes for the entire route from factory to port.

How Does Destination Transport Differ?

US and European regulations have different requirements. While China focuses on provincial regulations, the US has state-by-state requirements and Europe has country-specific rules for heavy transport.

Specialized carriers handle final destination delivery. Most standard trucking companies cannot handle heavy or oversized cargo, requiring specialized heavy haul carriers with appropriate equipment.

Permit processing times vary by destination. Some US states process oversize permits within hours, while others require days or weeks, significantly impacting project timing.

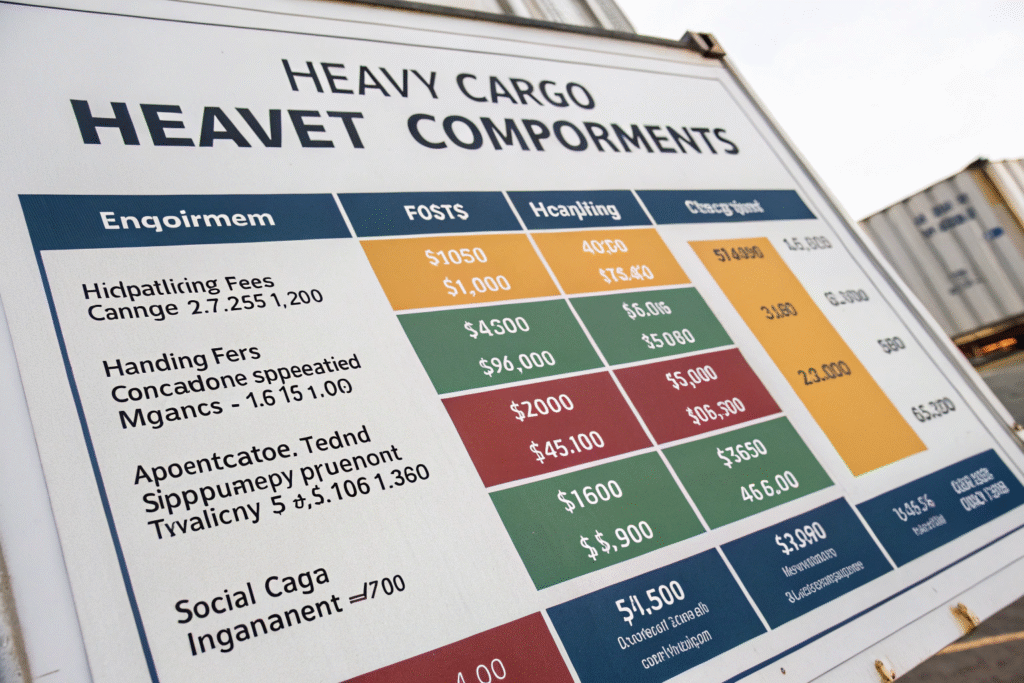

What Are the Critical Cost Considerations?

Heavy and project cargo shipping involves cost structures far more complex than standard container shipping.

What Are the Main Cost Drivers?

Equipment premiums for specialized containers add significant costs. Flat racks and open tops typically cost 50-150% more than standard containers, with platform containers commanding even higher premiums.

Handling charges for heavy lifts are substantially higher. While standard containers might incur $200-300 in handling charges, heavy lifts can cost $2,000-10,000 per lift depending on weight and complexity.

Permit and escort fees accumulate quickly. Oversized transport requires permits from multiple jurisdictions plus police escort costs that can total thousands of dollars per shipment.

How Can You Manage and Reduce Costs?

Accurate measurements prevent costly rehandling. Providing precise dimensions and weights from the beginning prevents equipment mismatches that require expensive reloading or equipment changes.

Consolidation with other project cargo creates economies. Shipping multiple project components together can reduce per-unit costs compared to shipping pieces individually.

Seasonal timing affects equipment availability and pricing. Avoiding peak shipping seasons when equipment is scarce can reduce costs by 15-30% for non-urgent shipments.

What Risk Management Strategies Are Essential?

Heavy and project cargo involves significant risks that require specific management approaches.

What Insurance Considerations Are Critical?

Specialized project cargo insurance differs from standard coverage. Standard marine cargo insurance often excludes heavy lifts, project cargo, and certain types of machinery, requiring specific project policies.

Delay in startup insurance protects against revenue loss. For equipment critical to operations, this coverage compensates for lost revenue if project delays prevent equipment from becoming operational on schedule.

Erection all risk insurance covers assembly and installation. This specialized coverage protects during the installation and commissioning phase, which standard transit policies exclude.

How Can You Prevent Damage and Loss?

Professional securing plans ensure cargo safety. Certified cargo securing plans created by naval architects or engineers prevent shifting during ocean transit that could damage cargo or vessel.

Proper lifting gear and procedures prevent handling damage. Using appropriate lifting equipment and following engineered lifting plans prevents damage to both cargo and lifting points.

Weather routing minimizes environmental risks. For sensitive equipment, vessels can route around severe weather, though this may increase transit time and cost.

Conclusion

Shipping heavy or project cargo from China requires specialized expertise, careful planning, and attention to details that standard shipments don't encounter. The most successful shippers treat project cargo as a specialized discipline rather than an extension of their regular shipping activities, recognizing that the stakes—and costs—are significantly higher.

At GeeseCargo, we've managed heavy cargo shipments ranging from individual machinery pieces to complete factory relocations, with the most successful outcomes coming from clients who engage early, provide accurate information, and maintain realistic expectations about timelines and costs. The key is recognizing that heavy cargo shipping follows different rules than standard logistics, requiring patience, expertise, and systematic planning.

Begin your heavy cargo planning by gathering precise measurements and weights, then engage experienced project forwarders who can guide equipment selection, routing, and documentation. Remember that with heavy and project cargo, the cost of prevention is always lower than the cost of correction—investing in proper planning, equipment, and insurance ultimately saves money and prevents headaches.