Many businesses struggle with the "black hole" in their supply chains - that period when shipments are in transit and no one knows exactly where they are or when they'll arrive. This lack of visibility can cause inventory problems, production delays, and customer dissatisfaction. Modern freight forwarders have transformed this challenge through technology and expertise.

Freight forwarders enhance supply chain visibility by implementing real-time tracking systems, providing centralized data platforms, offering predictive analytics, and maintaining proactive communication. These solutions give businesses complete transparency from origin to destination, enabling better decision-making and risk management.

Let's examine the specific tools and strategies that professional freight forwarders use to bring clarity and control to your global supply chain operations.

What tracking technologies do freight forwarders use?

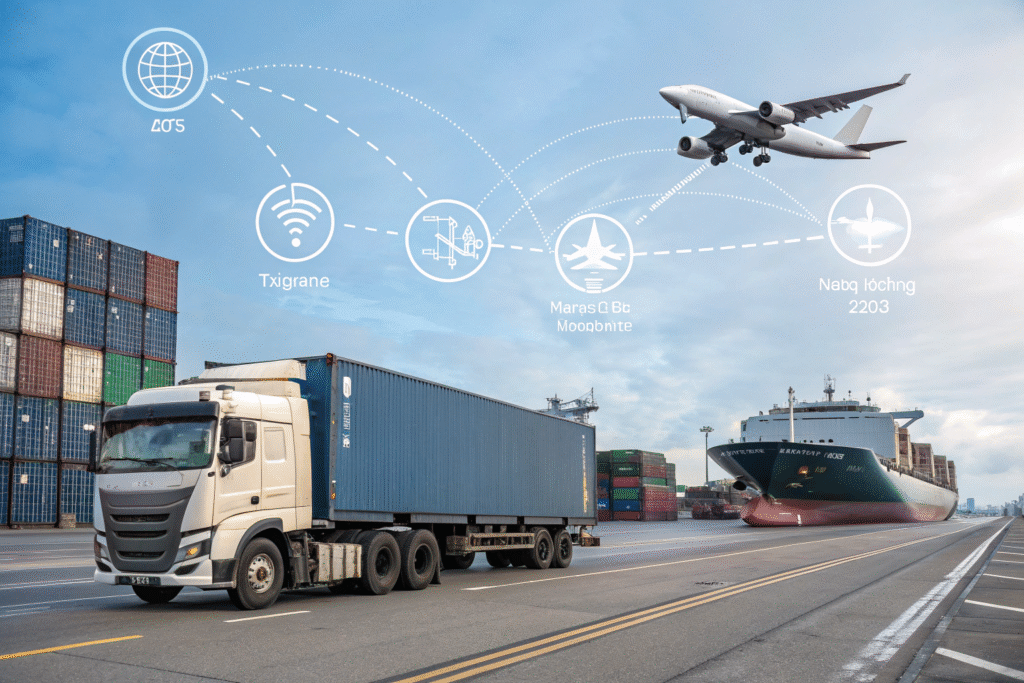

The days of wondering where your shipment is located are over. Today's freight forwarders employ multiple tracking technologies that provide precise, real-time location data. These technologies work together to create a comprehensive picture of your shipment's journey across all transportation modes.

Advanced forwarders use GPS tracking for trucks, AIS (Automatic Identification System) for ocean vessels, and flight tracking APIs for air cargo. Additionally, IoT sensors can monitor conditions inside containers, tracking temperature, humidity, and impacts. This multi-layered approach means we can pinpoint your shipment's location whether it's on a truck in China, a vessel in the Pacific, or a plane approaching its destination. The data feeds into centralized platforms that you can access anytime.

How do IoT sensors enhance shipment monitoring?

Internet of Things sensors provide crucial data beyond simple location tracking. These devices monitor:

- Temperature and humidity for sensitive products like electronics or pharmaceuticals

- Shock and impact to detect rough handling that could damage fragile goods

- Door openings to ensure container security throughout the journey

- Light exposure for light-sensitive products

This real-time condition monitoring allows for immediate intervention if parameters exceed safe ranges, preventing spoiled or damaged goods from reaching your customers.

What is the role of API integrations in visibility?

API (Application Programming Interface) integrations create seamless data exchange between different systems. Forwarders use APIs to connect directly with carrier systems, port operations, customs databases, and transportation management systems. This automated data sharing eliminates manual updates and provides the most current information available. Instead of waiting for email updates, you see carrier data directly in your tracking portal, ensuring accuracy and timeliness.

How do centralized platforms improve visibility?

Managing multiple spreadsheets, email chains, and carrier websites creates confusion and inefficiency. Centralized platforms solve this problem by bringing all supply chain information into one accessible location. This single source of truth transforms how businesses manage their logistics.

These platforms provide a unified dashboard showing all your shipments, documents, and communications. You can see real-time status updates, access important documents like bills of lading and commercial invoices, and view analytics on your shipping performance. The best platforms are accessible via web browser and mobile app, giving you 24/7 access to your supply chain data from anywhere in the world.

What key information should a visibility platform provide?

A comprehensive visibility platform should display:

- Real-time shipment location and estimated time of arrival

- Document status including customs clearance progress

- Container and vessel details for ocean shipments

- Carrier performance metrics and historical data

- Exception alerts for delays or problems

- Cost tracking against budget and quotes

This holistic view enables proactive management rather than reactive problem-solving.

How do exception alerts prevent supply chain disruptions?

Exception alerts automatically notify you when something unexpected occurs in your supply chain. For example, if a shipment misses its scheduled vessel, experiences customs delays, or encounters weather-related routing changes, the system immediately alerts both us and you. This early warning system allows for quick contingency planning, such as arranging alternative transportation or adjusting production schedules. Proactive problem management minimizes the impact of disruptions on your operations.

How does data analytics support better decision-making?

Raw tracking data has limited value without analysis and context. Forwarders transform this data into actionable insights through advanced analytics. These insights help businesses optimize their supply chains, reduce costs, and improve reliability.

Analytics platforms identify patterns in transit times, pinpoint frequent bottleneck locations, compare carrier performance, and forecast potential delays. For example, by analyzing historical data, we can predict how seasonal weather patterns might affect your shipments and recommend earlier cut-off dates. This predictive capability moves supply chain management from reactive to strategic.

![]()

What supply chain KPIs should businesses monitor?

Key Performance Indicators (KPIs) provide measurable insights into your supply chain health. Important metrics include:

- On-time delivery rate across all carriers and lanes

- Total transit time from pickup to final delivery

- Customs clearance duration in different countries

- Cost per unit by shipping lane and transportation mode

- Container utilization rates to optimize packing efficiency

Regular monitoring of these KPIs identifies improvement opportunities and tracks performance trends over time.

How can predictive analytics reduce risks?

Predictive analytics uses machine learning algorithms to forecast potential supply chain disruptions. By analyzing historical data combined with real-time information about weather, port congestion, and carrier schedules, these systems can identify shipments at high risk of delay. This allows for proactive measures like rerouting shipments, adjusting inventory levels, or communicating with customers about potential delays before they become critical issues.

How does communication enhance supply chain visibility?

Technology alone cannot guarantee good visibility - clear communication processes are equally important. The best freight forwarders combine advanced technology with consistent, proactive communication to keep clients fully informed.

We establish regular communication protocols including scheduled status updates, immediate notification of exceptions, and dedicated points of contact. This human layer ensures that you understand what the data means and have context for any issues that arise. Regular performance reviews help identify ongoing challenges and opportunities for improvement in your supply chain.

What makes supply chain reporting effective?

Effective supply chain reporting goes beyond simply presenting data. Good reports:

- Focus on relevant metrics that align with business objectives

- Provide context and explanation for unusual patterns or results

- Compare performance against benchmarks and previous periods

- Highlight actionable insights rather than just data points

- Are tailored to different stakeholders in your organization

Well-designed reports help different teams - from logistics to finance to sales - understand supply chain performance from their perspective.

How do regular performance reviews improve visibility?

Scheduled performance reviews create opportunities to step back from day-to-day operations and examine overall supply chain effectiveness. In these sessions, we analyze trends, discuss challenges, and identify optimization opportunities. This collaborative approach ensures that visibility tools are delivering value and aligned with your evolving business needs. The insights gained often lead to process improvements that benefit your entire operation.

Conclusion

Supply chain visibility is no longer a luxury but a necessity for businesses operating in global markets. Modern freight forwarders provide this visibility through a combination of advanced tracking technologies, centralized data platforms, analytical capabilities, and proactive communication. This comprehensive approach transforms logistics from a cost center into a strategic advantage, enabling better inventory management, improved customer service, and more resilient operations. By partnering with a forwarder that prioritizes visibility, businesses gain the clarity and control needed to thrive in today's complex global marketplace.