When one of our e-commerce clients started proper palletizing, they reduced their shipping costs by 34% and cut loading time from 6 hours to 45 minutes per container. As founder of GeeseCargo with extensive experience in cargo optimization, I've witnessed how strategic palletizing transforms shipping from a cost center to a competitive advantage. The benefits extend far beyond simple organization to impact nearly every aspect of your supply chain economics.

Proper palletizing reduces shipping costs by improving container utilization 15-30%, decreasing handling time 40-60%, reducing damage claims 25-50%, and optimizing labor efficiency. Standardized pallet loads also qualify for carrier discounts, streamline customs inspections, and enhance warehouse operations at both origin and destination.

Palletizing represents one of the most impactful yet underutilized strategies in international shipping. When implemented correctly, it creates efficiencies that compound throughout your supply chain, delivering significant cost reductions while improving reliability and protection.

How Does Palletizing Improve Container and Equipment Utilization?

Maximizing the use of available space directly translates to lower per-unit shipping costs and more efficient transportation asset utilization.

What Container Space Optimization Benefits Does Palletizing Provide?

Vertical space utilization increases dramatically with stable pallet loads. While loose cartons typically stack 4-5 feet high before becoming unstable, properly palletized goods can safely utilize the full container height up to 7.5-8 feet, increasing capacity 30-50%.

Cubic efficiency improves through consistent load dimensions. Uniform pallet loads eliminate the air gaps and irregular shapes that plague loose cargo, typically improving space utilization 15-25% in standard containers.

Weight distribution optimization prevents wasted capacity. Proper palletizing allows strategic placement of heavy and light items to maximize both weight and volume limits, particularly important in weight-restricted trade lanes.

How Does Palletizing Affect Equipment and Handling Efficiency?

Forklift accessibility reduces manual handling time and costs. Palletized loads can be moved in minutes versus hours for loose cargo, with a single forklift moving 20-30 pallets in the time needed to manually handle one pallet's worth of loose boxes.

Container turn-time reductions generate substantial cost savings. Faster loading and unloading means containers spend less time at facilities, reducing detention charges and improving equipment availability for subsequent shipments.

Intermodal transfer efficiency improves dramatically. Palletized cargo moves seamlessly between trucks, warehouses, and container yards without repacking, eliminating handling costs at each transfer point.

How Does Palletizing Reduce Damage and Associated Costs?

Cargo damage represents a hidden cost that often exceeds apparent savings from rushed or improper shipping methods. Proper palletizing dramatically reduces these losses.

What Types of Damage Does Proper Palletizing Prevent?

Compression damage elimination protects bottom layers from crushing. Without pallets, bottom cartons bear the weight of entire stacks, often collapsing under pressure during ocean transit or warehouse storage.

Handling impact reduction occurs through unitized loads. Individual cartons suffer impact damage during manual throwing or dropping, while palletized loads move as single units with mechanical equipment.

Moisture protection improves with proper stretch-wrapping. Pallet wrapping creates a moisture barrier and prevents water infiltration from floor contact or condensation, particularly important in ocean transit.

How Do Damage Reduction Benefits Translate to Cost Savings?

Insurance premium reductions of 10-25% are common for properly palletized shipments. Insurers recognize the risk reduction and often offer improved rates for shipments demonstrating professional packing standards.

Claim administration cost elimination saves both time and resources. Each damage claim requires 4-8 hours of administrative work plus potential customer relationship damage beyond the direct product loss.

Customer retention improves with consistent product condition. Repeated damage incidents erode customer trust and can permanently damage supplier relationships, while reliable delivery builds loyalty.

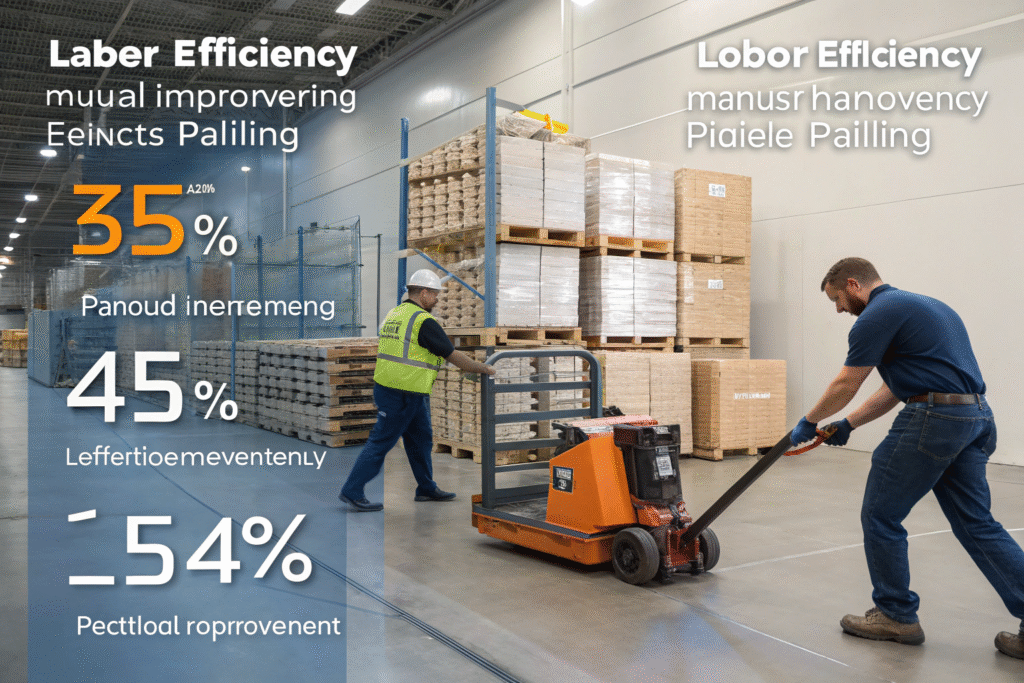

How Does Palletizing Create Labor and Time Efficiencies?

The labor cost savings from palletizing often exceed the transportation savings, particularly in regions with higher labor costs or limited workforce availability.

What Loading and Unloading Time Reductions Can You Expect?

Container loading time typically decreases from 4-8 hours to 1-2 hours for standard shipments. This 60-75% reduction translates directly to labor cost savings and improved facility throughput.

Warehouse receiving operations accelerate by 50-70%. Instead of manually handling individual cartons, receiving docks can process entire pallets in minutes, speeding inventory availability and reducing dock congestion.

Cross-docking efficiency improves for distribution operations. Palletized shipments can move directly from receiving to outbound staging without repacking, enabling faster order fulfillment and reduced handling.

How Does Palletizing Optimize Workforce Deployment?

Labor skill requirements decrease with palletized handling. Basic forklift operation replaces skilled manual loading labor, potentially reducing labor costs 30-50% while improving workforce safety.

Workforce scalability improves during peak periods. Temporary forklift operators can be trained quickly compared to skilled manual loaders, providing more flexible labor management during demand fluctuations.

Safety incident reduction lowers insurance and compensation costs. Manual handling injuries decrease significantly when palletizing eliminates heavy lifting and repetitive motion tasks.

What Are the Direct Carrier Cost Advantages?

Shipping carriers recognize and reward efficient cargo presentation through improved pricing, priority handling, and reduced ancillary charges.

What Pricing Incentives Do Carriers Offer for Palletized Cargo?

Volume-based rates become accessible through consistent load dimensions. Carriers can accurately predict space utilization with uniform pallets, often offering 5-15% better rates for predictable, efficient cargo.

Handling surcharge avoidance occurs with carrier-friendly pallet specs. Many carriers add special handling fees for loose cargo or non-standard pallets, while standard palletized shipments avoid these additional charges.

Priority loading access sometimes accompanies efficient shipments. Terminals often process palletized cargo faster, potentially securing better vessel space allocation during capacity constraints.

How Does Palletizing Affect Accessorial Charges?

Detention and demurrage reduction occurs through faster turnaround. Since palletized containers load and unload in 25-40% of the time required for loose cargo, the risk of exceeding free time allowances decreases significantly.

Rehandling charges elimination saves costs at transshipment points. When containers need inspection or transfer between vessels, palletized cargo avoids the rehandling fees that loose cargo often incurs.

Storage charge optimization results from better space utilization. Warehouses charge less for pallet storage than loose cargo storage due to better space utilization and handling efficiency.

How Can You Implement Cost-Effective Palletizing Strategies?

Successful palletizing requires balancing upfront investments against long-term savings through strategic implementation tailored to your specific shipping patterns.

What Pallet Selection Criteria Deliver Optimal Value?

Standard pallet specifications ensure carrier acceptance and handling efficiency. ISO pallets (1200×800mm or 1200×1000mm) work with most equipment globally, while regional standards may offer local advantages.

Pallet material choice affects both cost and performance. Wood pallets offer low upfront cost, plastic provides hygiene and durability, while paper and metal serve specialized applications with different cost structures.

Pallet pooling services like CHEP or LPR can reduce capital investment. For companies with fluctuating volume, rental pallets from pooling services may offer better economics than ownership despite higher per-use costs.

What Equipment and Process Investments Provide Quickest ROI?

Basic stretch-wrap systems cost $200-$2,000 but typically pay back in 3-6 months. Even manual wrap stations dramatically improve load stability and protection with minimal investment.

Forklift access represents the most significant infrastructure requirement. Whether owning equipment or using third-party services, mechanical handling capability is essential for palletizing benefits.

Layout optimization for pallet building and staging improves efficiency. Designing workflows that minimize movement between production, palletizing, and loading areas can reduce labor requirements 20-30%.

What Are the Hidden Considerations and Potential Drawbacks?

While palletizing offers significant benefits, understanding the potential challenges ensures successful implementation and avoids unexpected costs.

What Additional Costs and Considerations Should You Factor?

Pallet weight addition (15-25 kg per pallet) reduces payload capacity. In weight-restricted shipments, pallet weight directly reduces product payload, potentially requiring additional shipments for the same product volume.

Pallet cost represents both initial investment and ongoing replacement. Wood pallets typically last 5-10 trips, while plastic may last 50-100 trips, requiring different cost calculations based on shipment patterns.

Return logistics for pallets can create complexity and cost. Unless using disposable pallets or pooling services, pallet return or repositioning requires planning and expense that offsets some savings.

How Do You Balance Palletizing Benefits Against Specific Product Characteristics?

Product compatibility with palletizing varies by characteristics. Very small shipments, irregular shapes, or extremely fragile items may not benefit from standard palletizing approaches.

Customer requirements sometimes conflict with palletized shipping. Some distribution centers or retail customers require specific presentation that may not align with optimal shipping pallet configurations.

Seasonal fluctuations affect palletizing economics. Businesses with highly variable shipping volumes may find different optimal approaches for peak versus normal periods.

Conclusion

Palletizing represents one of the highest-return investments in logistics optimization, typically delivering 20-40% total cost reduction while improving supply chain reliability and product protection. The most successful implementations begin with careful analysis of current costs, followed by phased implementation that demonstrates quick wins while building toward comprehensive palletizing strategies.

At GeeseCargo, we've helped clients achieve an average of 28% shipping cost reduction through optimized palletizing, with the best results coming from companies that treat palletizing as an integrated system rather than a standalone activity. The key is balancing pallet costs against the compound savings across transportation, handling, damage prevention, and labor efficiency.

Begin your palletizing journey by conducting a thorough cost analysis of your current shipping methods, then pilot palletizing on your most suitable product lines. Remember that successful palletizing requires attention to both the technical aspects of load optimization and the operational aspects of implementation within your specific business context.