Asian supply chains face unprecedented challenges from geopolitical tensions, climate disruptions, trade policy shifts, and infrastructure limitations. Companies that relied on single-source, just-in-time models from Asia now confront vulnerabilities that can disrupt operations, increase costs, and threaten business continuity. Proactive risk mitigation has evolved from competitive advantage to business necessity.

You can mitigate Asian supply chain risks through supplier diversification, inventory strategy adjustments, logistics redundancy, compliance management, and technology-enabled visibility. A comprehensive approach typically reduces disruption impact by 60-80% and creates supply chain resilience that provides competitive advantage during market volatility.

Let's examine the specific strategies, implementation approaches, and balance between cost and resilience that will protect your business from Asian supply chain vulnerabilities.

How can supplier diversification reduce your vulnerability?

Supplier concentration represents one of the most significant risks in Asian sourcing, particularly when relying on single factories or geographic regions. Strategic diversification creates natural buffers against localized disruptions.

Effective diversification involves developing primary and secondary suppliers across different Asian regions—combining established Chinese manufacturers with emerging options in Vietnam, Thailand, India, or Malaysia. The approach should include capability mapping to ensure alternative suppliers can meet quality and technical requirements. Relationship development with backup suppliers ensures they're prepared to ramp up during disruptions. Additionally, multi-sourcing specific components across different suppliers prevents single points of failure. This diversification typically increases sourcing costs by 8-15% but reduces disruption risk by 60-70%.

What specific diversification strategies provide the best protection?

Effective diversification approaches:

- China-plus-one strategy maintaining Chinese suppliers while developing alternatives

- Regional specialization matching products to specific country capabilities

- Tiered supplier relationships with primary, secondary, and tertiary options

- Component multi-sourcing splitting critical components across suppliers

- Capability redundancy ensuring multiple suppliers can produce key items

These approaches create flexibility without completely abandoning established supplier relationships.

How do you maintain quality consistency during diversification?

Quality maintenance strategies:

- Standardized specifications ensuring all suppliers meet identical requirements

- Cross-supplier training sharing best practices and quality standards

- Third-party quality verification using independent inspection services

- Performance benchmarking comparing suppliers against established metrics

- Technical collaboration helping new suppliers achieve quality targets

Proper quality management ensures diversification doesn't compromise product standards.

How should you adjust inventory strategies for Asian volatility?

Inventory represents both cost and protection in volatile supply chains. Strategic inventory adjustments balance carrying costs against disruption risks, moving beyond traditional lean inventory models.

Safety stock levels should increase for critical components with long lead times or single-source dependencies. Strategic buffer inventory positioned in Asian hubs enables faster response to regional disruptions. In-transit inventory management should account for extended lead time variability. Inventory segmentation should prioritize protection for high-impact, difficult-to-replace items. These adjustments typically increase inventory carrying costs by 15-25% but reduce stockout risks by 70-80% during supply disruptions.

What inventory positioning strategies maximize flexibility?

Strategic inventory positioning:

- Asian hub inventory in strategic locations like Singapore, Hong Kong, or Dubai

- Regional distribution centers serving multiple markets with pooled inventory

- In-transit visibility with real-time tracking and diversion capabilities

- Supplier-managed inventory arrangements for critical components

- Cross-docking operations minimizing storage while maintaining flow

Proper positioning ensures inventory is accessible when and where needed during disruptions.

How can technology improve inventory decision-making?

Inventory optimization technologies:

- Demand sensing platforms detecting demand pattern changes in real-time

- Inventory optimization software calculating optimal stock levels across nodes

- Lead time analytics tracking variability and adjusting safety stock accordingly

- Scenario modeling tools simulating disruption impacts on inventory needs

- Integration platforms connecting inventory systems across supply chain partners

These technologies transform inventory from static protection to dynamic risk management.

What logistics redundancies provide the most value?

Logistics networks represent critical vulnerability points in Asian supply chains, with port congestion, carrier capacity issues, and infrastructure limitations creating frequent bottlenecks. Strategic redundancy ensures alternative pathways when primary routes face disruption.

Multi-modal strategies combine ocean, air, and rail options based on urgency and cost requirements. Port diversification uses alternative gateways when primary ports face congestion. Carrier relationships with multiple providers ensure capacity access during peak periods. Routing flexibility allows dynamic path adjustments based on current conditions. These redundancies typically increase logistics costs by 10-20% but prevent catastrophic disruptions that can cost weeks of delays.

Which logistics redundancies deliver the best cost-benefit balance?

High-value logistics redundancies:

- Port alternatives for both Asian origins and destination markets

- Multi-carrier relationships ensuring capacity during peak demand

- Intermodal options seamlessly switching between transportation modes

- Emergency air freight arrangements for critical shipment acceleration

- Regional consolidation hubs enabling shipment reconfiguration during transit

These redundancies provide significant protection without excessive cost increases.

How can you build logistics flexibility into operations?

Flexibility development strategies:

- Carrier contract structures that guarantee capacity during disruptions

- Relationship development with niche or specialized carriers

- Technology integration providing real-time visibility across all logistics options

- Process standardization enabling seamless transitions between carriers

- Performance monitoring identifying reliable partners during challenging conditions

Operational flexibility ensures redundancies can be activated effectively when needed.

How does compliance management reduce regulatory risks?

Asian supply chains face increasing regulatory complexity from trade policies, customs requirements, sustainability mandates, and security regulations. Proactive compliance management prevents costly delays, penalties, and reputational damage.

Comprehensive compliance programs should address forced labor due diligence requirements, export control regulations, customs compliance standards, product safety requirements, and environmental regulations. Supplier vetting processes must verify compliance capabilities before engagement. Documentation systems should maintain complete records supporting compliance claims. Regular audits should verify ongoing compliance with evolving requirements. These measures typically increase administrative costs by 5-10% but prevent regulatory disruptions that can halt shipments entirely.

What specific compliance areas require focused attention?

High-priority compliance areas:

- Forced labor due diligence particularly for specific regions and industries

- Export control compliance for regulated technologies and destinations

- Customs valuation accuracy preventing penalties and shipment delays

- Product certification requirements for different market regulations

- Environmental regulations covering materials, packaging, and manufacturing

These areas represent the most common sources of regulatory disruption.

How can technology streamline compliance management?

Compliance technology applications:

- Automated documentation systems ensuring consistency and completeness

- Supplier compliance portals collecting and verifying supplier information

- Regulatory monitoring platforms tracking requirement changes

- Risk assessment tools identifying highest-compliance-risk shipments

- Audit management systems organizing compliance verification activities

Technology transforms compliance from administrative burden to strategic advantage.

What role does supply chain visibility play in risk mitigation?

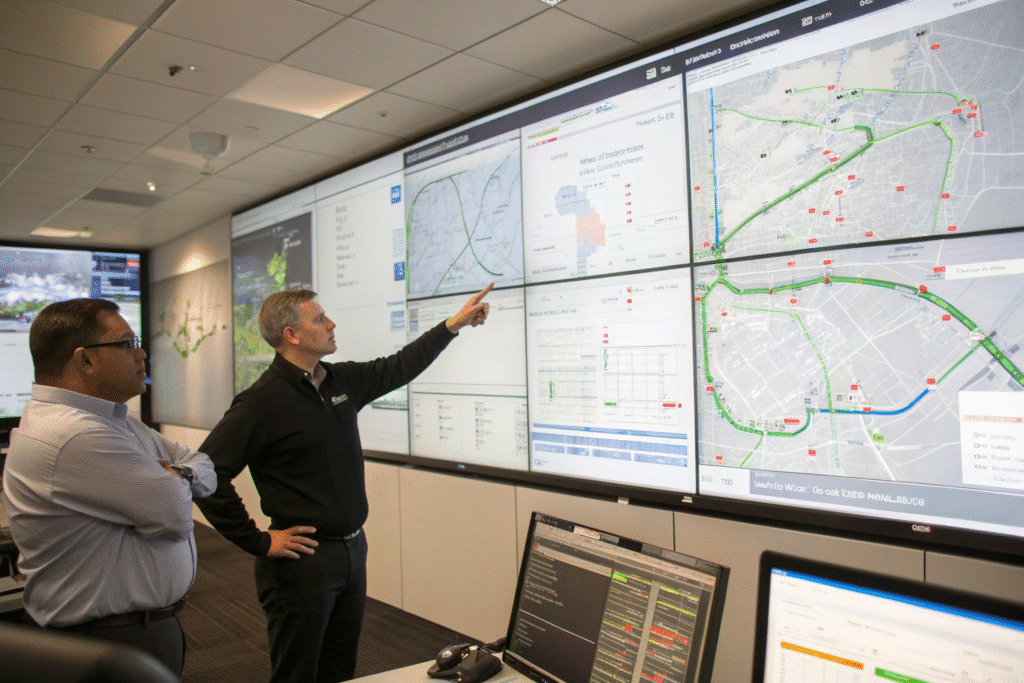

Visibility represents the foundation of effective risk management, enabling proactive response rather than reactive firefighting. Comprehensive visibility across Asian supply chains requires technology investment and partner collaboration.

Real-time tracking should cover inventory in transit, production status at suppliers, capacity availability at logistics providers, and potential disruptions along routes. Predictive analytics should identify potential bottlenecks before they cause delays. Exception management systems should automatically flag issues requiring intervention. Partner integration should create seamless information flow across organizational boundaries. These visibility capabilities typically require technology investment of 1-3% of supply chain costs but enable disruption responses that save 10-30% in avoided impacts.

What visibility capabilities provide the most risk reduction?

High-impact visibility features:

- Real-time container tracking with predictive arrival updates

- Production status monitoring at supplier facilities

- Capacity visibility across logistics and transportation providers

- Disruption early warning from weather, political, or operational events

- Inventory visibility across all storage locations and in transit

These capabilities transform supply chain management from reactive to predictive.

How can you achieve visibility without overwhelming complexity?

Visibility implementation strategies:

- Phased approach starting with highest-risk supply chain segments

- API integration creating seamless data exchange between systems

- Data standardization ensuring consistency across different sources

- Alert prioritization focusing attention on most critical exceptions

- Partner collaboration developing shared visibility benefits

Strategic implementation makes comprehensive visibility manageable and actionable.

Conclusion

Mitigating Asian supply chain risks requires a balanced approach combining supplier diversification, strategic inventory, logistics redundancy, compliance management, and comprehensive visibility. The most successful companies treat risk mitigation as an ongoing strategic function rather than a reactive activity, building resilience that becomes a competitive advantage during market disruptions. While these measures involve additional costs, they prevent far greater losses during supply chain failures. By implementing a comprehensive risk mitigation strategy, businesses can continue leveraging Asian sourcing advantages while protecting themselves from the region's unique vulnerabilities and uncertainties.