When time is critical, every hour counts in air freight shipping from China. Many businesses face frustrating delays despite paying premium rates for air transportation. The journey involves multiple handoffs where inefficiencies can creep in, turning what should be a 3-5 day process into a week-long ordeal. Understanding where delays occur and how to address them can significantly accelerate your shipments.

To make your air freight from China arrive faster, prioritize direct flights over transshipments, ensure complete documentation ready before shipment, use airlines with better ground handling, choose forwarders with strong airline relationships, and consider premium services like express air freight. These strategies can reduce transit time by 1-3 days compared to standard air cargo.

Let's examine the specific bottlenecks that slow air freight and the practical strategies to accelerate each stage of the shipping process.

How does flight selection impact delivery speed?

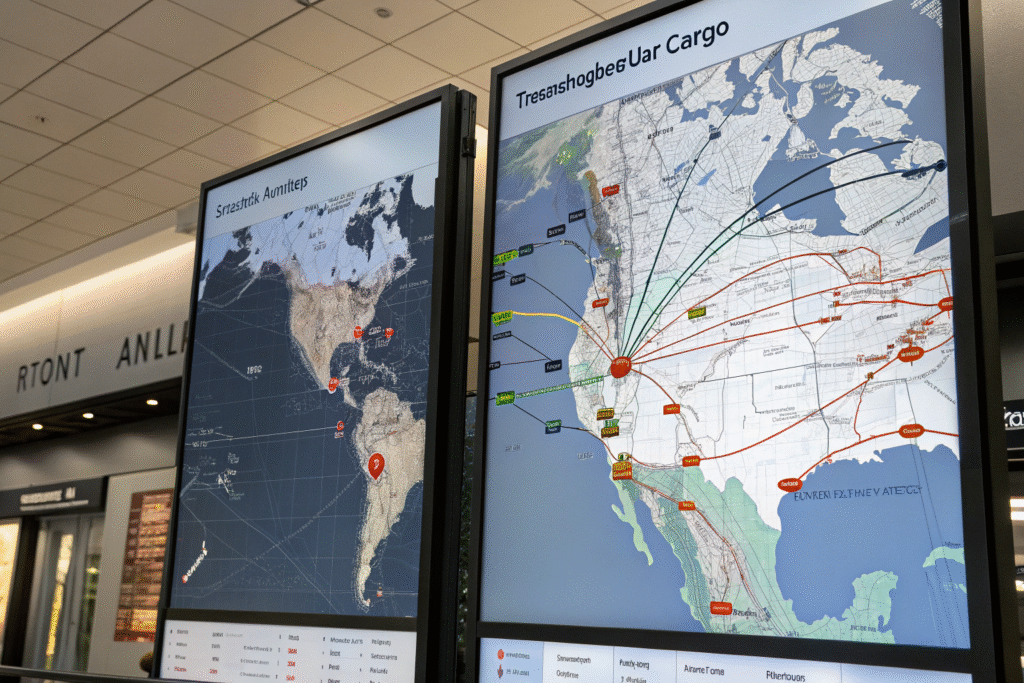

The choice between direct flights and transshipment routes represents the most significant factor in air freight speed. Many shipments follow circuitous routes that add days to transit time without obvious cost savings.

Direct flights from major Chinese airports like Shanghai (PVG), Beijing (PEK), or Shenzhen (SZX) to US hubs like Los Angeles (LAX), Chicago (ORD), or New York (JFK) typically complete the journey in 2-4 days. Transshipped cargo routed through intermediate hubs like Seoul (ICN), Tokyo (NRT), or Anchorage (ANC) can take 5-8 days due to additional handling, potential missed connections, and customs processing at each stop. The most significant time savings come from selecting carriers and forwarders that prioritize direct routing over cost optimization.

What are the hidden time costs of transshipment?

Transshipment creates multiple delay points:

- Additional unloading and reloading adding 8-24 hours at each hub

- Connection waiting time if cargo misses tight transfer windows

- Secondary security screening required at many transit airports

- Duplicate documentation checks by different ground handlers

- Customs processing in transit countries for certain commodities

These cumulative delays often negate any cost savings from indirect routing.

Which Chinese airports offer the best direct connectivity?

Major Chinese airports with excellent US connectivity:

- Shanghai (PVG): Most direct flights to US destinations across multiple carriers

- Beijing (PEK): Strong direct connectivity particularly to West Coast hubs

- Shenzhen (SZX): Growing direct services especially for electronics cargo

- Guangzhou (CAN): Good direct options particularly for Southern China

- Hong Kong (HKG): Extensive direct network despite additional border crossing

Selecting the optimal departure airport based on your factory location saves significant time.

How can documentation preparation prevent delays?

Documentation issues represent the most common and preventable cause of air freight delays. Incomplete or inaccurate paperwork can stop shipments at multiple points, creating cascading delays that extend far beyond the time needed to correct errors.

Complete documentation must be ready before cargo arrives at the airport. This includes commercial invoice, packing list, air waybill, export declarations, and any required certificates. The most efficient shippers maintain digital document templates that can be quickly customized for each shipment. Having documents prepared in advance allows for pre-clearance processing and prevents cargo being held at Chinese airports awaiting proper documentation.

What specific documents cause the most delays?

Common problematic documents include:

- Commercial invoices missing required elements like detailed product descriptions

- Packing lists with discrepancies in weight, dimensions, or contents

- Air waybills containing errors in consignee information or special handling codes

- Export declarations with incorrect HS codes or values

- Certificates of origin lacking proper authentication or details

Addressing these common issues prevents most documentation-related delays.

How can technology accelerate documentation processing?

Digital solutions provide significant time savings:

- Automated document generation from template libraries

- Electronic submission to carriers and customs authorities

- Data validation catching errors before submission

- Digital signatures eliminating physical document transfer

- Cloud storage providing instant access to all stakeholders

These technologies can reduce documentation processing from days to hours.

What operational strategies improve handling efficiency?

Ground operations at both origin and destination airports create significant bottlenecks in air freight. The time between cargo arrival at the airport and actual aircraft loading often exceeds the flight time itself.

Choose forwarders with strong relationships with ground handlers at key Chinese airports. These relationships often translate to priority handling, better equipment access, and faster problem resolution. Additionally, consider premium services that guarantee specific flight bookings rather than space-available shipping. For truly urgent shipments, charter services eliminate handling delays entirely by providing dedicated aircraft and customized scheduling.

How do airline relationships affect transit time?

Strong carrier relationships provide:

- Guanteed space on specific flights rather than standby status

- Priority loading ensuring cargo makes intended departures

- Better equipment access during peak periods

- Faster issue resolution when problems occur

- Flexibility to accommodate last-minute changes

These advantages can save 12-48 hours during tight shipping windows.

What value do premium air services offer?

Express air freight services provide:

- Defined cut-off times closer to flight departure

- Priority unloading upon arrival at destination

- Expedited customs clearance with pre-submitted documentation

- Dedicated handling teams familiar with urgent shipments

- Enhanced tracking with more frequent status updates

These services typically deliver goods 1-2 days faster than standard air cargo.

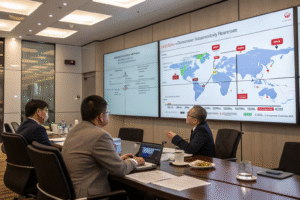

How can customs clearance be accelerated?

Customs processing represents a major potential delay point in air freight, particularly for regulated commodities or during increased security periods. Proactive clearance strategies can dramatically reduce this bottleneck.

Utilize pre-clearance programs that submit documentation while cargo is still in transit. Maintain trusted shipper status with customs authorities when possible. Ensure complete accuracy in product description and classification. Use customs brokers with specific experience in your commodity type and strong relationships with customs officials. These approaches can transform customs clearance from a 2-3 day process to a matter of hours.

What pre-clearance strategies save the most time?

Effective pre-clearance approaches include:

- Advanced submission of complete documentation packages

- Pre-arrival processing by customs authorities

- Risk assessment completion before cargo arrival

- Electronic data interchange with customs systems

- Relationship building with key customs personnel

These strategies can reduce customs clearance from days to hours.

How does commodity knowledge affect clearance speed?

Specialized understanding helps because:

- Accurate classification prevents review requests

- Proper documentation meets specific commodity requirements

- Regulatory awareness ensures complete compliance

- Experience with examinations prepares for likely inspections

- Industry relationships facilitate communication with specialists

This expertise prevents the delays that plague inexperienced shippers.

What role does packaging play in transit time?

Proper packaging affects air freight speed in multiple ways beyond simple physical protection. Efficient packaging can reduce handling time, prevent security delays, and optimize space utilization.

Use standardized packaging that fits efficiently into air cargo containers. Ensure packaging meets airline requirements for weight distribution and security. Include clear labeling that facilitates quick handling and sorting. Use materials that won't trigger additional security screening. Proper packaging prevents the delays that occur when cargo requires repacking at the airport or receives special handling due to packaging deficiencies.

How does packaging affect security screening?

Packaging considerations for security:

- Transparent packaging for certain commodities reduces inspection needs

- Proper sealing prevents tampering concerns that trigger inspections

- Clear labeling of contents facilitates risk assessment

- Standard dimensions fit automated screening equipment

- Avoidance of problematic materials that require special handling

These factors can save hours in security processing.

What packaging optimizes airline handling?

Airline-friendly packaging features:

- Uniform dimensions for efficient containerization

- Appropriate weight distribution for safe handling

- Clear handling instructions in multiple languages

- Standard pallet configurations matching airline equipment

- Adequate protection preventing damage that causes delays

Optimized packaging transforms handling from a bottleneck into an efficiency.

Conclusion

Accelerating air freight from China requires a comprehensive approach addressing flight selection, documentation, operations, customs, and packaging. The most significant time savings come from choosing direct flights, ensuring perfect documentation readiness, leveraging strong carrier relationships, implementing customs pre-clearance, and optimizing packaging for air transport. Businesses that systematically address each of these areas typically achieve transit times 30-50% faster than those taking a passive approach. While some strategies involve additional costs, the time savings often justify the expense through reduced inventory carrying costs, better customer service, and increased business agility. By implementing these accelerated shipping approaches, you can transform air freight from a necessary expense into a competitive advantage.