Achieving true end-to-end supply chain visibility remains one of the most significant challenges—and opportunities—for modern businesses. Many companies operate with fragmented visibility, seeing only isolated segments of their supply chain while critical information gaps create vulnerabilities, inefficiencies, and missed opportunities. Comprehensive visibility transforms supply chain management from reactive firefighting to proactive optimization.

You can achieve better supply chain visibility by implementing integrated technology platforms, establishing data standards across partners, deploying IoT tracking devices, and creating centralized control towers. Companies that achieve comprehensive visibility typically reduce inventory costs by 15-30%, improve on-time delivery by 25-40%, and decrease supply chain disruption impacts by 50-70%.

Let's examine the specific strategies, technologies, and implementation approaches that create true end-to-end visibility across your entire supply chain from raw materials to end customer.

What technology foundations enable true end-to-end visibility?

The technological foundation for supply chain visibility requires integrated systems that collect, normalize, and analyze data from multiple sources across your extended supply chain. This goes far beyond simple tracking to encompass predictive analytics and automated decision support.

Modern visibility platforms typically combine Transportation Management Systems (TMS), Warehouse Management Systems (WMS), Enterprise Resource Planning (ERP) integrations, Internet of Things (IoT) sensors, Application Programming Interfaces (APIs) for partner connectivity, and advanced analytics engines. The most effective implementations create a "single source of truth" that aggregates data from all systems and partners, normalizes it into consistent formats, and provides actionable insights through intuitive dashboards and automated alerts. This technological foundation typically requires 6-18 months to implement fully but delivers compounding returns through improved decision-making and risk reduction.

What specific integration points deliver the most visibility value?

High-impact integration targets:

- Supplier production systems providing real-time manufacturing status and capacity information

- Carrier tracking systems delivering precise location and condition data throughout transit

- Warehouse management platforms showing inventory levels, order status, and facility capacity

- Customs brokerage interfaces providing clearance status and potential delay alerts

- Financial systems connecting physical flow with financial transactions and obligations

- Customer systems offering demand signals and consumption patterns

These integrations create the data foundation for true end-to-end visibility.

How can API ecosystems accelerate visibility implementation?

API-driven visibility advantages:

- Rapid partner onboarding through standardized connection protocols

- Real-time data exchange eliminating manual updates and information lag

- Scalable architecture accommodating new partners and data sources easily

- Automated data validation ensuring information quality and consistency

- Flexible analytics enabling custom reporting and KPI tracking

- Cost-effective expansion reducing per-connection implementation expenses

API-first approaches typically reduce visibility implementation time by 40-60% compared to traditional integration methods.

How can IoT and tracking technologies enhance visibility?

Internet of Things devices and advanced tracking technologies provide real-time, granular visibility into shipment location, condition, and potential disruptions. These technologies transform visibility from periodic updates to continuous monitoring.

Modern IoT solutions include smart containers with GPS, temperature, humidity, and shock sensors; pallet-level tracking devices providing location updates every 15-30 minutes; warehouse IoT networks monitoring inventory movement and storage conditions; port and terminal sensors tracking container movements and dwell times; and predictive analytics platforms that combine IoT data with external factors like weather, traffic, and port congestion. These technologies typically increase visibility costs by 0.5-2.0% of shipment value but reduce loss, damage, and delay costs by 8-15%.

What IoT applications provide the highest return on investment?

High-ROI IoT implementations:

- Temperature monitoring for climate-sensitive products reducing spoilage by 80-90%

- Shock and impact detection identifying rough handling and enabling proactive quality interventions

- Real-time location tracking eliminating search times and enabling dynamic routing

- Container door sensors detecting unauthorized access and preventing theft

- Predictive maintenance on transportation assets preventing breakdowns and delays

- Condition monitoring ensuring product integrity throughout the journey

These applications typically pay for themselves within 6-18 months through reduced losses and improved efficiency.

How can you implement IoT without overwhelming complexity?

Phased IoT implementation strategy:

- Start with high-value shipments where the stakes justify technology costs

- Focus on critical pain points rather than attempting comprehensive coverage initially

- Use provider-managed solutions reducing internal technical requirements

- Implement gradually across transportation modes and product categories

- Build internal expertise through focused pilot programs before scaling

- Establish clear ROI metrics to guide expansion decisions based on results

This approach makes IoT implementation manageable while delivering meaningful visibility improvements.

What role do data standards and partner collaboration play?

Visibility depends fundamentally on consistent data standards and collaborative relationships across your supply chain ecosystem. The most sophisticated technology platforms fail without reliable, standardized data from partners.

Effective visibility requires establishing data standards for product identification, location codes, time stamps, status definitions, and exception classifications. It demands collaborative relationships where partners share information proactively rather than defensively. It involves creating mutual benefits so visibility investments deliver value to all participants. Successful companies typically invest 20-30% of their visibility budget on partner onboarding, training, and incentive programs to ensure ecosystem-wide participation and data quality.

How can you encourage partner data sharing?

Effective partner engagement strategies:

- Shared performance dashboards showing how visibility benefits all participants

- Process efficiency improvements that reduce administrative burdens for partners

- Financial incentives for timely, accurate data sharing and problem resolution

- Collaborative planning using shared visibility to optimize joint operations

- Transparent performance scoring creating accountability for data quality

- Technical support helping partners implement required connectivity

These approaches transform data sharing from obligation to opportunity for partners.

What data standards are most critical for visibility?

Essential visibility standards:

- GS1 identification standards for consistent product, location, and shipment identification

- EDIFACT or XML messaging standards for electronic data interchange

- ISO time and date formats ensuring temporal consistency across systems

- UN/LOCODE location codes providing standardized geographic references

- Standardized status definitions ensuring consistent interpretation of shipment progress

- Common exception classifications enabling automated problem categorization and routing

These standards create the linguistic foundation for supply chain visibility.

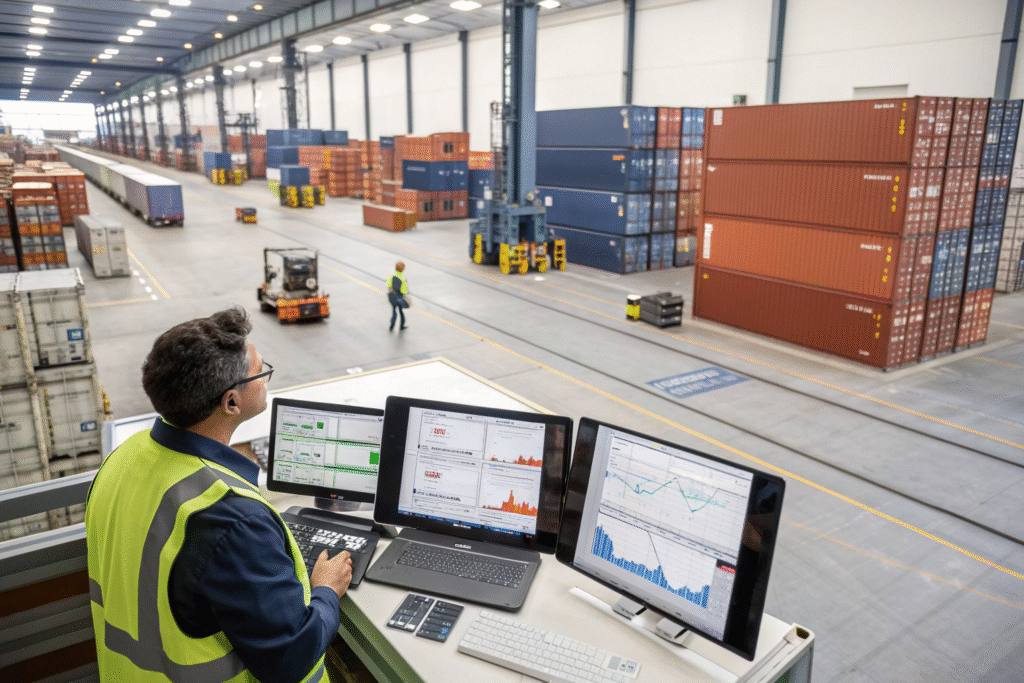

How can control towers and analytics transform visibility into action?

Visibility without action provides limited value. Control towers and advanced analytics transform raw visibility data into actionable insights, predictive alerts, and automated responses that improve supply chain performance.

Modern control towers typically combine real-time monitoring, predictive analytics, exception management, and resolution workflows. They use machine learning to identify patterns suggesting potential disruptions days before they occur. They automate routine decisions while escalating exceptions to appropriate personnel with context and recommended actions. They provide simulation capabilities to evaluate alternative responses to emerging situations. Companies implementing advanced control towers typically achieve 25-40% faster response to disruptions and 15-30% reduction in exception handling costs.

What control tower capabilities deliver the most value?

High-impact control tower functions:

- Predictive delay alerts flagging potential disruptions 3-7 days in advance

- Automated exception routing sending issues to the most appropriate resolver

- Performance analytics identifying trends and improvement opportunities

- Scenario simulation evaluating alternative responses to emerging situations

- Resource optimization dynamically allocating assets based on current conditions

- Stakeholder communication providing timely, accurate updates to all affected parties

These capabilities transform visibility from observational to operational.

How can analytics identify improvement opportunities?

Advanced analytical approaches:

- Root cause analysis identifying underlying reasons for recurring issues

- Pattern recognition detecting subtle correlations that signal emerging risks

- Performance benchmarking comparing operations across lanes, partners, and time periods

- Predictive modeling forecasting potential outcomes based on current trajectories

- Constraint analysis identifying bottlenecks limiting overall supply chain performance

- Optimization algorithms suggesting improvements to routing, inventory, and resource allocation

These analytical capabilities typically identify improvement opportunities worth 3-8% of total supply chain costs annually.

What implementation approach ensures visibility success?

Successful visibility implementation requires careful planning, phased execution, and continuous improvement. The most effective approaches balance comprehensive vision with practical, incremental implementation that delivers measurable value at each stage.

Begin with a current state assessment identifying critical visibility gaps and their business impacts. Develop a phased roadmap starting with high-impact, achievable initiatives that demonstrate quick wins. Establish clear metrics and ROI calculations to guide prioritization and measure progress. Build cross-functional implementation teams combining supply chain, technology, and business expertise. Create feedback mechanisms to continuously refine visibility capabilities based on user experience and changing business needs. This approach typically delivers initial meaningful visibility within 3-6 months while building toward comprehensive capabilities over 18-36 months.

What quick wins build momentum for visibility initiatives?

Effective quick win candidates:

- Shipment tracking portal providing real-time status for customer service teams

- Exception alert system flagging delayed or problematic shipments automatically

- Inventory visibility for critical SKUs across key distribution centers

- Supplier performance dashboards highlighting delivery and quality trends

- Transportation analytics identifying cost and service improvement opportunities

- Customs clearance tracking reducing uncertainty and storage charges

These focused initiatives typically deliver 5-15% cost savings or service improvements within 3-6 months.

How can you measure visibility ROI effectively?

Comprehensive ROI measurement:

- Reduced inventory levels through better demand sensing and lead time predictability

- Lower transportation costs through optimized routing and mode selection

- Decreased loss and damage through proactive monitoring and intervention

- Improved customer service through accurate ETAs and exception management

- Reduced premium freight through better planning and disruption anticipation

- Labor productivity improvements through automated monitoring and reporting

Tracking these metrics demonstrates visibility's tangible business value beyond simple operational improvements.

Conclusion

Achieving comprehensive supply chain visibility requires integrated technology, IoT implementation, data standardization, partner collaboration, and advanced analytics working together. The most successful companies treat visibility as a strategic capability rather than a tactical project, investing in the foundations that enable continuous improvement and adaptation. While achieving true end-to-end visibility requires significant effort and investment, the returns through reduced costs, improved service, and greater resilience typically deliver substantial competitive advantage. By implementing a structured, phased approach focused on delivering measurable value at each stage, companies can transform their supply chains from opaque cost centers to transparent, optimized value drivers.