When one of our e-commerce clients grew from $50,000 to $2 million in annual sales, their turning point came when they stopped managing logistics themselves and partnered with our 3PL. As founder of GeeseCargo, I've witnessed how the right logistics partnership can transform businesses from struggling with operations to focusing on growth. Scaling requires more than just increasing sales—it demands a supply chain that grows with you.

A China-based 3PL helps scale your business through warehouse consolidation, inventory management, quality control, and streamlined shipping. These services reduce costs by 15-30%, improve delivery times by 40-60%, and eliminate operational bottlenecks that constrain growth. The right partnership acts as your extended logistics department, allowing you to focus on sales and product development.

Scaling a business with international suppliers presents unique challenges that often overwhelm internal resources. A professional 3PL doesn't just store and ship goods—they become strategic partners in your growth journey. Let's explore the specific ways they enable scalable operations.

How Does Warehouse Consolidation Reduce Costs and Complexity?

Managing multiple suppliers across China creates logistical nightmares that drain resources and increase errors. Warehouse consolidation transforms this chaos into streamlined efficiency.

How Does Multi-Supplier Coordination Work?

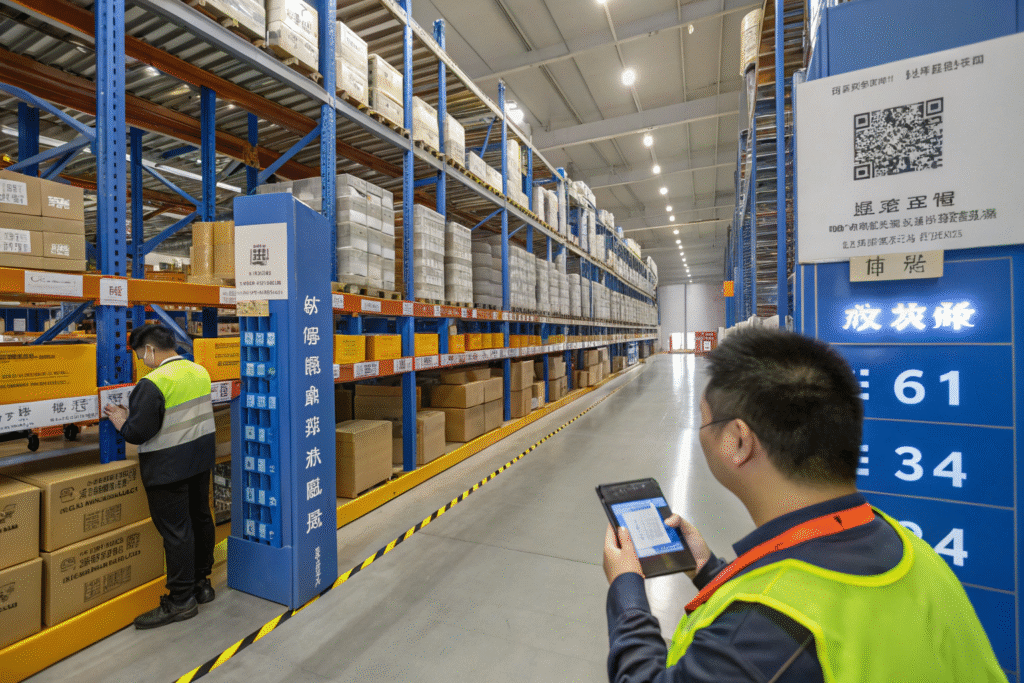

A 3PL receives goods from all your suppliers at their consolidation warehouse, creating a single point of contact. Instead of coordinating with ten different factories for shipping, you work with one professional team. This reduces communication errors and ensures consistent handling procedures.

The 3PL inspects, records, and stores incoming goods using standardized processes. They verify quantities against your purchase orders and check for visible damage. This immediate quality gate prevents problems from escalating downstream.

Consolidation allows for weekly or bi-weekly shipments instead of individual factory dispatches. This regularity improves container utilization and reduces per-unit shipping costs. The consistent schedule also helps with cash flow planning and inventory forecasting.

What Are the Inventory Management Benefits?

Real-time inventory visibility transforms how you manage stock levels and reordering. Modern 3PLs provide dashboard access showing exact quantities, locations, and movement history. This data-driven approach eliminates guesswork and stockouts.

Seasonal fluctuations become manageable with flexible storage solutions. During peak periods, you can increase warehouse space, then scale down during slower months. This pay-as-you-use model beats maintaining fixed warehouse capacity.

Safety stock calculations become more accurate with historical data analysis. Your 3PL can recommend optimal reorder points based on lead times, sales velocity, and seasonal patterns. This proactive approach prevents both overstocking and stockouts.

How Does Quality Control Support Business Growth?

Maintaining product quality while scaling is perhaps the biggest challenge importers face. A 3PL becomes your eyes and ears on the ground, ensuring consistency as order volumes increase.

What Pre-Shipment Inspection Services Matter?

Professional inspection services catch defects before goods leave China, saving thousands in return costs. Inspectors check functionality, workmanship, materials, packaging, and labeling against your specifications. Early detection allows for factory corrections without international shipping delays.

Random sampling based on international standards (AQL) provides statistical confidence in quality levels. The inspection scope can target known problem areas or conduct comprehensive reviews. Either approach provides objective data for supplier performance evaluation.

Documentation through photos, videos, and detailed reports creates accountability. When issues arise, you have evidence to support chargebacks or rework requests. This documentation also helps suppliers improve their processes over time.

How Does Quality Data Inform Business Decisions?

Tracking defect patterns across suppliers and product categories reveals important trends. You can identify which factories consistently deliver quality and which need improvement. This data supports strategic sourcing decisions as you expand your product lines.

Quality metrics help negotiate better terms with suppliers. Factories knowing they face professional inspection tend to maintain higher standards. The inspection process itself encourages better performance through accountability.

Customer return analysis helps pinpoint recurring issues. By understanding why products get returned, you can address root causes rather than symptoms. This continuous improvement cycle enhances customer satisfaction as you scale.

How Do Shipping Optimization Strategies Reduce Costs?

Shipping costs typically represent 10-15% of product costs for importers, making optimization crucial for scaling profitably. 3PLs leverage volume and expertise to secure better rates and terms.

How Does Freight Negotiation Benefit Scaling Businesses?

3PLs aggregate volume across multiple clients to negotiate better rates with carriers. This collective purchasing power provides access to pricing typically reserved for enterprise-level shippers. The savings directly impact your bottom line.

Carrier relationships developed over years provide priority treatment during capacity crunches. When shipping space gets tight, established 3PL clients get allocated space while others face delays. This reliability is crucial for maintaining customer satisfaction during growth.

Multi-modal expertise ensures optimal routing and method selection. Your 3PL can combine sea, air, and rail transport to balance cost and speed. This flexibility becomes increasingly valuable as your shipping volumes and complexity grow.

What Inventory Distribution Strategies Support Growth?

Strategic warehouse placement in China reduces domestic transportation costs and time. Positioning inventory near major ports cuts transit time and handling. Some 3PLs maintain multiple warehouse locations for geographical optimization.

Demand-based inventory allocation matches stock levels with regional sales patterns. Higher-selling regions maintain larger inventory buffers while newer markets operate with leaner stock. This data-driven approach improves working capital efficiency.

Cross-docking services for fast-moving items eliminate storage entirely. Goods move directly from receiving to outbound shipping, reducing handling costs and transit time. This approach works well for predictable, high-volume products.

How Does Technology Integration Enable Scalable Operations?

Manual processes that work for small volumes become bottlenecks during growth. Modern 3PLs provide technology platforms that automate and streamline operations.

What Real-Time Visibility Features Matter Most?

Inventory tracking down to the SKU level provides accurate stock information across locations. This visibility prevents overselling and supports accurate financial planning. Real-time updates eliminate the need for manual spreadsheet tracking.

Order management integration automates fulfillment from order capture to delivery. When a customer places an order, the system automatically routes it to the optimal fulfillment location. This automation reduces processing time from hours to minutes.

Shipping status tracking keeps customers informed from warehouse pickup to final delivery. Automated notifications reduce customer service inquiries and improve satisfaction. The data also helps identify shipping carrier performance issues.

How Does Data Analytics Support Business Decisions?

Inventory turnover analysis identifies slow-moving items before they become obsolete. This insight supports promotional planning and purchasing decisions. Removing stagnant inventory frees up capital for better-performing products.

Shipping cost analytics reveal opportunities for further optimization. You can identify which products have disproportionate shipping costs relative to their value. This analysis supports packaging optimization and pricing strategy adjustments.

Customer delivery performance data highlights geographical variations in service levels. This information supports decisions about additional distribution centers or carrier diversification. The goal is consistent customer experience regardless of location.

Conclusion

A China-based 3PL transforms from a service provider to a strategic growth partner as your business scales. The cost savings, operational efficiency, and expertise they provide create foundations for sustainable expansion. More importantly, they free your team to focus on product development, marketing, and customer acquisition—the true drivers of growth.

At GeeseCargo, we've helped hundreds of businesses navigate the transition from manual logistics management to professional 3PL partnerships. The most successful implementations start with clear communication of business objectives and evolve through regular performance reviews and strategic planning.

Remember that scaling requires building systems that work without constant oversight. A professional 3PL provides these systems from day one, allowing you to grow faster and more confidently. The right partnership doesn't just support your growth—it accelerates it.