When one of our pharmaceutical clients shipped $2.3 million in temperature-sensitive vaccines using new blockchain-enabled smart containers, they achieved 99.97% temperature compliance and reduced insurance premiums by 28%. As founder of GeeseCargo with extensive cold chain experience, I've witnessed how recent innovations are transforming temperature-controlled logistics from a risk management challenge to a competitive advantage.

The latest cold chain innovations include IoT-enabled real-time monitoring, blockchain for chain of custody verification, solar-powered reefers, phase change materials (PCMs), and AI-powered predictive analytics. These technologies typically reduce temperature excursions by 60-85%, lower energy consumption by 25-40%, and improve supply chain visibility from 65% to over 95% for temperature-sensitive shipments.

Cold chain technology is advancing rapidly across monitoring, packaging, transportation, and data analytics. The most innovative companies are integrating multiple technologies to create resilient, transparent, and efficient temperature-controlled supply chains.

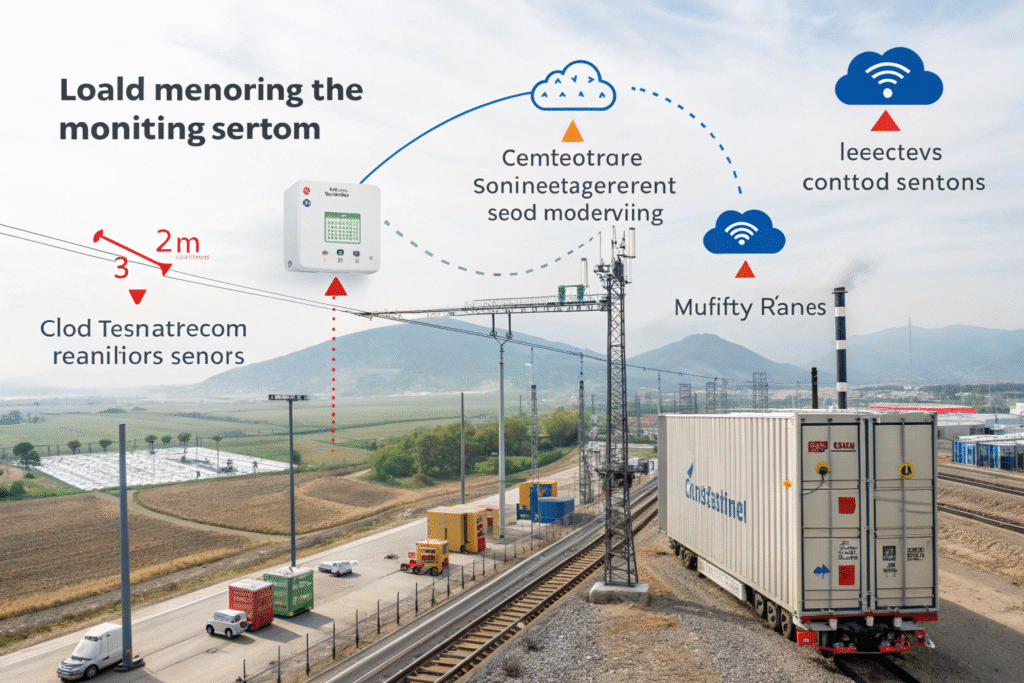

How Are IoT and Real-Time Monitoring Transforming Visibility?

Internet of Things technology provides unprecedented visibility into shipment conditions throughout the entire cold chain journey.

What Types of Smart Monitoring Systems Are Emerging?

Multi-parameter sensors track beyond basic temperature. Modern monitors measure humidity, light exposure, shock, tilt, and door openings, providing comprehensive condition monitoring rather than just temperature tracking.

Wireless connectivity enables real-time intervention. Cellular, satellite, and LoRaWAN connections transmit data continuously, allowing proactive response to issues rather than post-shipment discovery of problems.

Predictive analytics forecast potential excursions. AI algorithms analyze historical data and real-time conditions to predict potential temperature deviations before they occur, enabling preventive action.

How Does Real-Time Data Create Operational Value?

Immediate alerting enables rapid response to equipment failures. When refrigeration units malfunction or temperatures drift, real-time alerts allow technicians to address issues before product damage occurs.

Dynamic routing optimizes shipment handling. If temperature excursions occur during transit, systems can automatically reroute shipments to alternative facilities or expedite handling to minimize exposure.

Compliance automation simplifies regulatory documentation. Continuous monitoring automatically generates compliance reports for pharmaceuticals, food safety, and other regulated products.

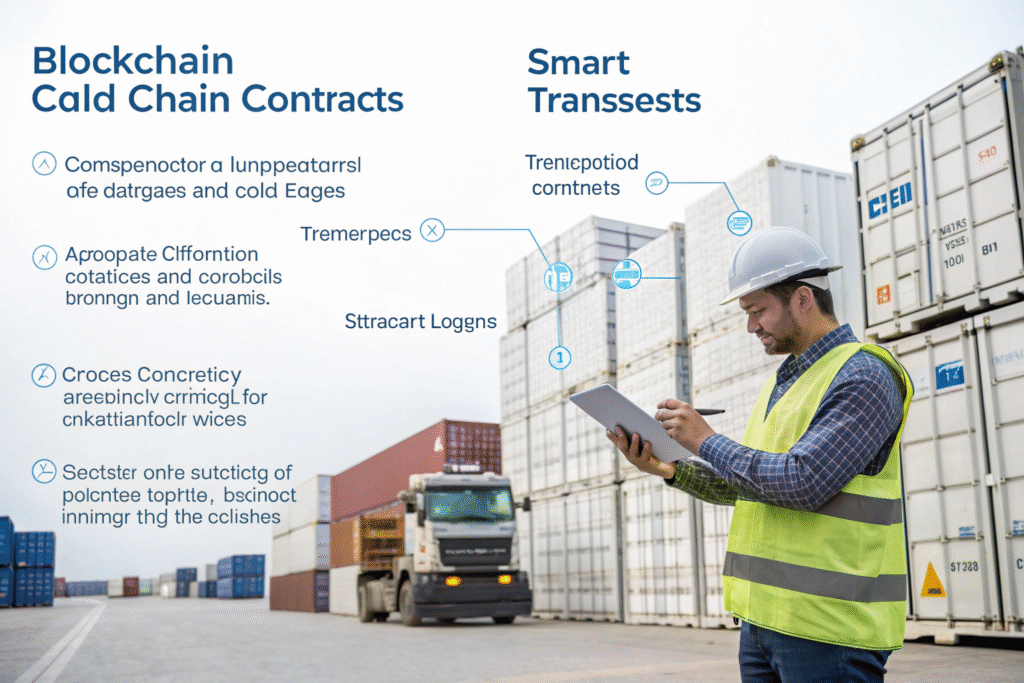

What Role Is Blockchain Playing in Cold Chain Assurance?

Blockchain technology creates immutable, transparent records of temperature conditions and custody transfers.

How Does Blockchain Improve Chain of Custody?

Immutable temperature records prevent data manipulation. Unlike traditional systems where temperature data can be altered, blockchain creates tamper-proof records that regulatory agencies and customers can trust.

Automated smart contracts execute based on condition verification. Payments, insurance claims, and quality approvals can automatically trigger when temperature conditions meet predefined criteria throughout the shipment journey.

Transparent access creates trust across supply chain partners. All authorized parties can access the same verified data, reducing disputes and improving collaboration between shippers, carriers, and receivers.

What Practical Applications Are Delivering Value Today?

Pharmaceutical supply chains use blockchain for regulatory compliance. COVID-19 vaccine distributions demonstrated how blockchain can verify temperature maintenance for sensitive biological products.

Food safety applications track from farm to table. High-value perishables like seafood, meats, and fresh produce use blockchain to verify temperature maintenance and build consumer trust.

Clinical trial materials leverage blockchain for audit trails. Temperature-sensitive research materials require impeccable documentation that blockchain provides efficiently.

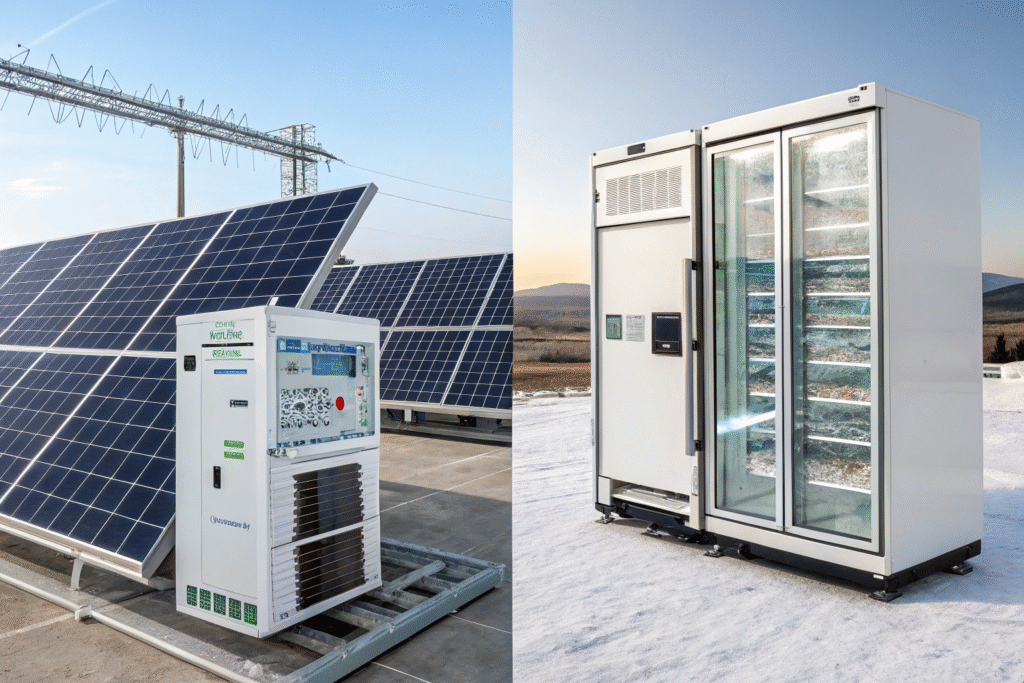

How Are Renewable Energy and Efficiency Innovations Evolving?

Sustainability and efficiency improvements are transforming cold chain equipment and operations.

What Alternative Power Systems Are Gaining Traction?

Solar-assisted reefers reduce generator fuel consumption. Integrated photovoltaic panels can provide 15-30% of refrigeration power, significantly reducing emissions and operating costs.

Electric and hybrid reefers eliminate port emissions. All-electric containers powered by lithium batteries eliminate noise and emissions during port operations, with some models offering full electric transit capability.

Hydrogen fuel cells provide zero-emission power for long hauls. For routes without electrical infrastructure, hydrogen fuel cells offer emission-free operation with only water as a byproduct.

How Is Thermal Efficiency Improving?

Advanced insulation materials dramatically reduce energy requirements. Vacuum insulated panels and aerogel materials provide superior thermal performance with thinner profiles, increasing payload capacity.

Phase change materials (PCMs) provide passive temperature buffering. These materials absorb and release thermal energy at specific temperatures, maintaining stable conditions during power interruptions or door openings.

Energy recovery systems capture waste heat. Advanced reefers can recover waste heat from refrigeration systems to power other functions or pre-condition incoming air.

What Packaging Innovations Are Enhancing Product Protection?

Smart packaging technologies work synergistically with transportation systems to maintain product integrity.

How Are Smart Packaging Technologies Evolving?

Time-temperature indicators provide visual excursion alerts. These inexpensive labels change color permanently when temperature thresholds are exceeded, providing immediate visual warning of potential product compromise.

Electronic temperature loggers integrated into packaging. Disposable or reusable loggers built into packaging provide detailed temperature history without additional handling or setup.

Connected packaging enables item-level tracking. Individual packages with embedded sensors and connectivity provide granular visibility into multi-pallet shipments where different items may experience different conditions.

What Advanced Materials Are Improving Thermal Performance?

Biodegradable phase change materials offer sustainable temperature control. New plant-based PCMs provide effective temperature buffering while addressing environmental concerns about traditional materials.

Metallic lining materials enhance thermal reflectivity. Advanced metallized films and coatings improve thermal performance by reflecting radiant heat more effectively than traditional materials.

Composite insulation combines multiple material advantages. Layered materials combining aerogels, vacuum panels, and traditional insulation provide optimal performance for specific temperature ranges and duration requirements.

How Is AI and Predictive Analytics Optimizing Cold Chains?

Artificial intelligence transforms cold chain data into actionable insights and predictive capabilities.

What Predictive Capabilities Are AI Systems Delivering?

Equipment failure prediction enables proactive maintenance. AI algorithms analyze performance data from refrigeration units to identify patterns preceding failures, allowing maintenance before breakdowns occur.

Route optimization based on weather and traffic conditions. Machine learning models incorporate real-time weather, traffic, and facility capacity data to dynamically optimize routes for temperature stability and efficiency.

Demand forecasting improves inventory positioning. Predictive analytics help position temperature-sensitive inventory closer to anticipated demand, reducing transit time and exposure risk.

How Does Machine Learning Improve Operational Decisions?

Anomaly detection identifies subtle pattern deviations. AI systems can detect minor temperature fluctuations or equipment performance changes that humans might miss, enabling early intervention.

Root cause analysis accelerates problem resolution. When temperature excursions occur, AI can quickly analyze multiple data sources to identify the most likely causes and recommend corrective actions.

Continuous optimization learns from every shipment. Machine learning algorithms progressively improve their recommendations based on outcomes from previous decisions and shipments.

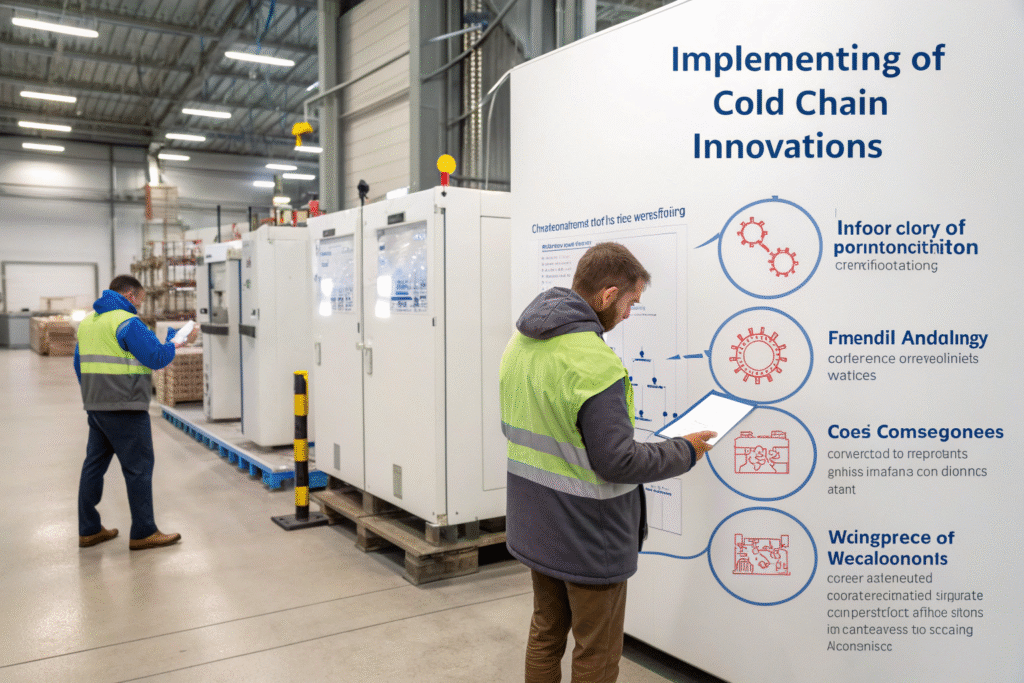

What Are the Implementation Challenges and Considerations?

While cold chain innovations offer significant benefits, successful implementation requires addressing specific challenges.

What Technical and Integration Challenges Exist?

Legacy system integration creates compatibility issues. New monitoring and control systems must integrate with existing ERP, WMS, and transportation management platforms.

Data standardization enables cross-platform functionality. Different systems using different data formats and communication protocols create integration complexity and data silos.

Cybersecurity requirements add implementation complexity. Connected cold chain systems represent additional attack surfaces that require robust security measures.

What Economic and Operational Factors Affect Adoption?

Return on investment calculations must account for reduced product loss. The business case for cold chain innovations often depends on preventing costly temperature excursions rather than just efficiency gains.

Workforce training requirements ensure proper technology use. New systems require training for operators, technicians, and managers to achieve full benefit.

Regulatory compliance varies across regions and industries. Different countries and product categories have varying requirements for temperature monitoring and documentation.

Conclusion

Cold chain shipping is undergoing its most significant transformation in decades, driven by converging technologies that enhance visibility, efficiency, and reliability. The most successful companies are those integrating multiple innovations to create resilient, transparent, and sustainable temperature-controlled supply chains rather than implementing point solutions in isolation.

At GeeseCargo, we've helped clients achieve 70-90% reductions in temperature excursions through strategic implementation of cold chain innovations. The most effective approaches combine advanced monitoring, smart packaging, and predictive analytics to create systems that not only respond to issues but prevent them from occurring.

Begin your cold chain innovation journey by identifying your highest-value opportunities—whether reducing product loss, improving regulatory compliance, or enhancing customer trust—then implement technologies that directly address these priorities. Remember that in cold chain logistics, technological advancement isn't just about operational improvement; it's about enabling new business models and market opportunities that require flawless temperature control.