When one of our clients faced $18,700 in demurrage charges for a single container stuck at Long Beach port for 11 days, I realized how many importers underestimate these escalating fees. As founder of GeeseCargo with extensive port operations experience, I've witnessed demurrage evolve from occasional nuisance to major cost driver that can erase profit margins on entire shipments.

Demurrage refers to charges imposed by marine terminals when import containers remain in their facilities beyond the allowed free time. These fees typically start 4-7 days after vessel arrival and escalate rapidly, often doubling every 2-3 days. A single container can accumulate $5,000-$15,000 in demurrage within two weeks, with some ports charging over $400 per day per container after the initial free period.

Demurrage differs from detention charges (for keeping equipment outside terminals) but both represent significant avoidable costs. Understanding the triggers, fee structures, and avoidance strategies is crucial for cost-effective importing in today's congested port environments.

What Exactly Triggers Demurrage Charges?

Demurrage calculations follow specific timelines and conditions that vary by port, carrier, and terminal operator.

How Do Free Time Periods Work at Different Ports?

Standard free time typically ranges from 4-7 calendar days at most US ports. Major ports like Los Angeles/Long Beach generally offer 4-5 free days, while some East Coast ports may provide 6-7 days before demurrage begins.

Free time calculation starts when containers become available for pickup. This typically occurs 1-2 days after vessel arrival, once containers are unloaded, processed, and positioned in the terminal yard.

Weekends and holidays usually count in free time calculations. Unlike business days for many commercial activities, demurrage free time typically includes weekends and holidays at most ports.

What Factors Influence Demurrage Rates and Structures?

Port congestion levels directly impact demurrage policies. During peak congestion, ports may reduce free time or increase rates to encourage faster container movement.

Terminal operator policies create significant variations. Different terminals within the same port may have different free time periods, rates, and escalation structures.

Carrier-specific demurrage programs add complexity. Some carriers have their own demurrage charges separate from terminal fees, particularly for specialized equipment or refrigerated containers.

What Are the Most Effective Demurrage Avoidance Strategies?

Proactive management and systematic processes can prevent most demurrage situations rather than reacting to accumulating fees.

How Can Advanced Planning Prevent Demurrage Issues?

Pre-arrival documentation submission ensures prompt customs release. Having all import documents submitted and approved before vessel arrival eliminates customs-related delays that consume free time.

Appointment scheduling immediately upon vessel arrival secures early pickup slots. Many ports allow appointment booking before containers are actually available, enabling same-day pickup once containers are released.

Trucker pre-booking during known busy periods ensures equipment availability. Scheduling transportation before vessel arrival prevents last-minute trucker shortages that cause delays.

What Operational Excellence Practices Reduce Demurrage Risk?

Real-time container tracking provides early warning of potential delays. Monitoring vessel arrival, terminal processing, and release status enables proactive response to developing issues.

Dedicated demurrage management creates accountability and expertise. Assigning specific staff to monitor free time and coordinate pickup prevents responsibility gaps that lead to overlooked containers.

Performance measurement of supply chain partners identifies improvement opportunities. Tracking which truckers, brokers, or terminals consistently cause delays enables targeted process improvements.

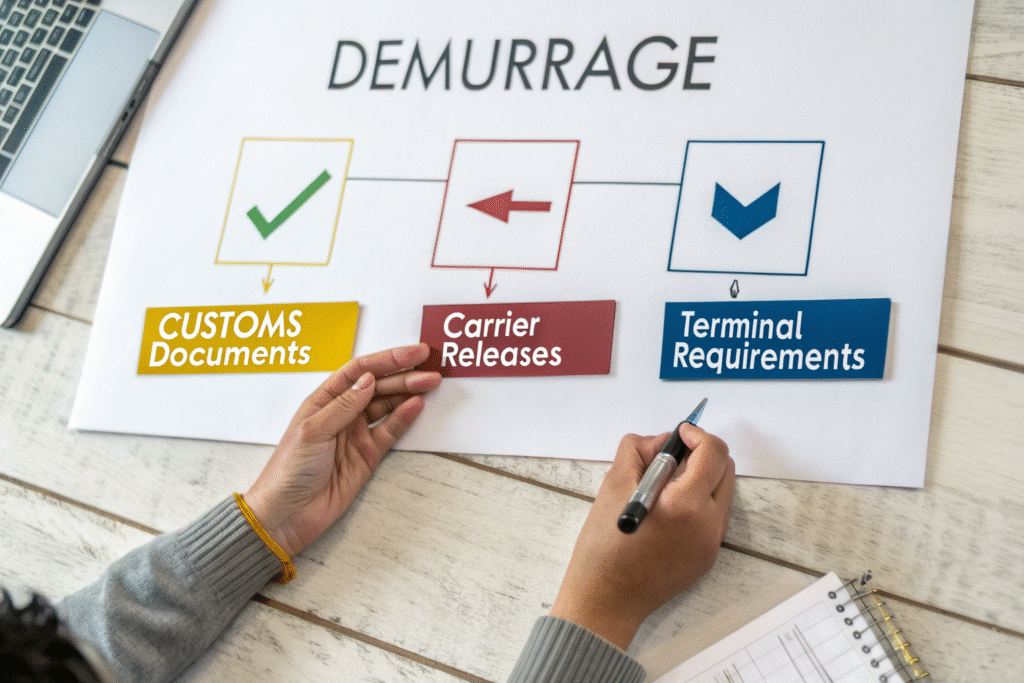

How Does Documentation Management Affect Demurrage?

Proper documentation handling is the foundation of demurrage prevention, as paperwork delays represent the most common demurrage trigger.

What Documents Are Critical for Timely Container Release?

Bill of Lading surrender or telex release enables cargo release. The original B/L must be surrendered or electronic release obtained before carriers will authorize terminal release.

Customs release documentation must be properly submitted and approved. Entry documents, PGA submissions, and duty payments must be complete before customs will release cargo.

Terminal-specific requirements may include additional documents. Some terminals require specific forms, identification, or processing before allowing container pickup.

How Can Documentation Processes Be Optimized?

Electronic document submission accelerates processing. Using ACE e-manifest, electronic B/L, and digital PGA submissions significantly reduces processing time compared to paper documentation.

Document preparation before vessel arrival creates time buffers. Having all required documents ready before vessels berth enables immediate submission upon arrival.

Centralized document management prevents misfiling or delays. Maintaining all import documents in a single system with clear status tracking prevents overlooked requirements.

What Role Do Transportation Partners Play in Demurrage Prevention?

Your choices and management of transportation providers significantly impact demurrage risk and costs.

How Should Truckers Be Managed to Minimize Demurrage?

Appointment scheduling efficiency varies significantly between truckers. Some trucking companies excel at securing prompt appointments while others consistently struggle during peak periods.

Equipment availability directly affects pickup capability. Truckers with chassis pools or reliable equipment access can respond faster than those dependent on third-party equipment.

Terminal familiarity influences efficiency and problem-solving. Truckers experienced with specific terminals understand unique requirements and can navigate issues more effectively.

What Performance Metrics Help Select Reliable Partners?

First-attempt pickup rate measures reliability. The percentage of appointments where truckers successfully pick up containers on the first attempt indicates operational efficiency.

Average time from release to pickup indicates responsiveness. Tracking how quickly truckers retrieve containers after release helps identify the most responsive providers.

Problem resolution capability distinguishes exceptional partners. Some truckers can resolve terminal issues, documentation problems, or equipment failures that would cause delays for less capable providers.

What Technology Solutions Help Manage Demurrage Risk?

Modern technology provides powerful tools for demurrage management through visibility, automation, and analytics.

What Visibility Tools Provide Early Warning?

Real-time container tracking monitors free time consumption. Systems that track vessel arrival, terminal processing, and free time remaining enable proactive management before demurrage begins.

Port community systems provide terminal-specific information. Many ports offer systems showing container status, appointment availability, and terminal conditions that affect pickup timing.

Carrier and terminal portals offer release status and demurrage accrual. Most carriers and terminals provide online access to container status and accumulating charges.

How Can Automation Reduce Demurrage Risk?

Automated document submission ensures timely filing. Systems that automatically submit required documents upon vessel arrival prevent oversight or delay.

Appointment scheduling automation secures optimal time slots. Tools that automatically book appointments when containers become available prevent scheduling delays.

Alert systems notify stakeholders of impending demurrage. Automated warnings when free time is running low enable last-minute interventions to prevent charges.

What Are the Most Common Demurrage Mistakes?

Understanding frequent errors helps importers avoid preventable demurrage situations.

What Planning Errors Cause Demurrage Problems?

Inadequate free time buffer for unexpected delays. Assuming perfect operations without contingency for weekends, weather, or unexpected issues guarantees eventual demurrage.

Poor coordination between supply chain partners. When importers, brokers, truckers, and consignees operate without synchronized planning, containers inevitably get overlooked.

Underestimating port-specific complexity. Treating all ports equally despite significant variations in operations, congestion, and requirements causes preventable delays.

What Execution Failures Lead to Demurrage?

Last-minute documentation preparation causes submission delays. Waiting until vessels arrive to prepare documents guarantees consumption of valuable free time.

Ineffective communication between departments. When logistics, accounting, and operations teams don't share container status information, containers slip through cracks.

Poor trucker management and performance monitoring. Without tracking trucker performance or maintaining backup options, unreliable service causes predictable demurrage.

Conclusion

Demurrage represents a significant but manageable cost in international shipping. The most successful importers treat demurrage prevention not as a reactive cost control measure but as an integral component of their supply chain strategy. By implementing systematic processes, leveraging technology, and maintaining strong partner relationships, companies can virtually eliminate avoidable demurrage while minimizing unavoidable charges.

At GeeseCargo, we've helped clients reduce demurrage costs by an average of 82% through comprehensive demurrage management programs. The most effective approaches combine advanced planning, real-time visibility, and continuous process improvement rather than relying on any single solution.

Begin your demurrage reduction by analyzing your historical demurrage patterns to identify root causes, then implement structured processes that address your specific vulnerability points. Remember that in demurrage management, prevention is dramatically more cost-effective than reaction—the modest investment in prevention systems typically returns 5-10x in avoided demurrage charges.