When one of our pharmaceutical clients shipped $500,000 worth of temperature-sensitive vaccines from Shanghai to Chicago, they discovered that choosing the right refrigerated shipping method made the difference between perfect condition arrival and total cargo loss. As founder of GeeseCargo with extensive experience in temperature-controlled logistics, I've learned that refrigerated shipping requires precision planning far beyond standard freight. The "best" method depends entirely on your product's specific temperature requirements, value, and shelf life.

The optimal shipping method for refrigerated goods from China balances temperature control precision, transit time, and cost. For most shipments, ocean reefers offer the best value for large volumes with tight temperature ranges (-25°C to +25°C), while air freight provides speed for high-value, time-sensitive goods. Critical considerations include proper pre-cooling, continuous temperature monitoring, and contingency planning for equipment failures.

Shipping refrigerated goods successfully requires understanding the complete cold chain from manufacturer to final destination, not just selecting a transportation mode. The most reliable approaches build multiple layers of protection and monitoring to ensure product integrity throughout the journey.

What Are the Main Refrigerated Shipping Options?

Different temperature-controlled transportation methods serve various needs based on cargo characteristics, urgency, and budget constraints.

When Should You Choose Ocean Reefer Containers?

Ocean reefers excel for large volume shipments with stable temperature requirements. Standard 40-foot high-cube reefers provide 67-72 cubic meters of temperature-controlled space, making them cost-effective for shipments over 5 CBM.

Temperature consistency is superior for non-urgent shipments. Modern reefers maintain temperatures within ±0.3°C of set points, providing stability that air freight sometimes struggles with during multiple handlings.

Cost efficiency is significant for large volumes. Ocean reefer costs are typically 60-80% lower than air freight for equivalent volumes, though transit times of 25-40 days require adequate product shelf life.

When Is Air Freight the Better Choice?

Time-sensitive products with short shelf lives require air freight. Perishable foods, live organisms, and certain pharmaceuticals with limited stability periods need the 2-5 day transit times air freight provides.

High-value goods justify air freight premiums. When product value exceeds $100 per kilogram, the inventory carrying cost reduction and shelf life preservation often justify air freight's higher costs.

Small shipments under 2 CBM work better via air. Airline container options accommodate smaller volumes efficiently, while ocean reefers become cost-prohibitive for very small shipments.

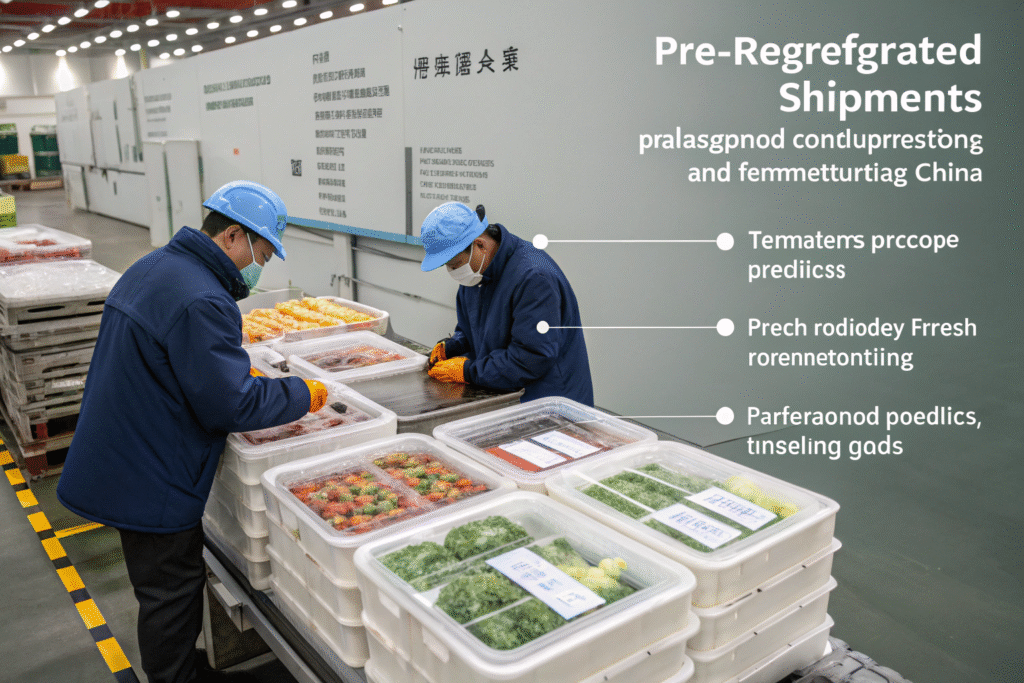

How Should You Prepare Temperature-Sensitive Shipments?

Proper preparation and packaging determine whether refrigerated goods arrive in perfect condition or suffer temperature excursions that compromise quality.

What Pre-Cooling Procedures Are Essential?

Product core temperature must reach target before loading. Loading warm products into reefers causes temperature spikes, condensation, and compressor overload that can compromise the entire shipment.

Facility temperature matching prevents thermal shock. The loading area, transportation equipment, and storage facilities should maintain temperatures within 3°C of the target shipping temperature.

Documentation of pre-cooling provides verification. Temperature logs from the manufacturing facility through loading create an audit trail that demonstrates proper handling from origin.

What Packaging Configurations Protect Temperature Integrity?

Insulated packaging provides thermal buffering during handling. Expanded polystyrene (EPS), vacuum insulated panels, or thick corrugated materials protect against short temperature excursions during transfers.

Phase change materials (PCMs) add thermal mass for stability. These materials absorb and release thermal energy at specific temperatures, providing additional protection during power interruptions or equipment cycling.

Proper air circulation prevents hot spots. Packaging must allow adequate airflow around products while providing sufficient insulation, requiring careful design for specific product characteristics.

What Monitoring and Documentation Ensure Quality?

Continuous monitoring and proper documentation create the verification needed to ensure product integrity and facilitate quality claims when issues occur.

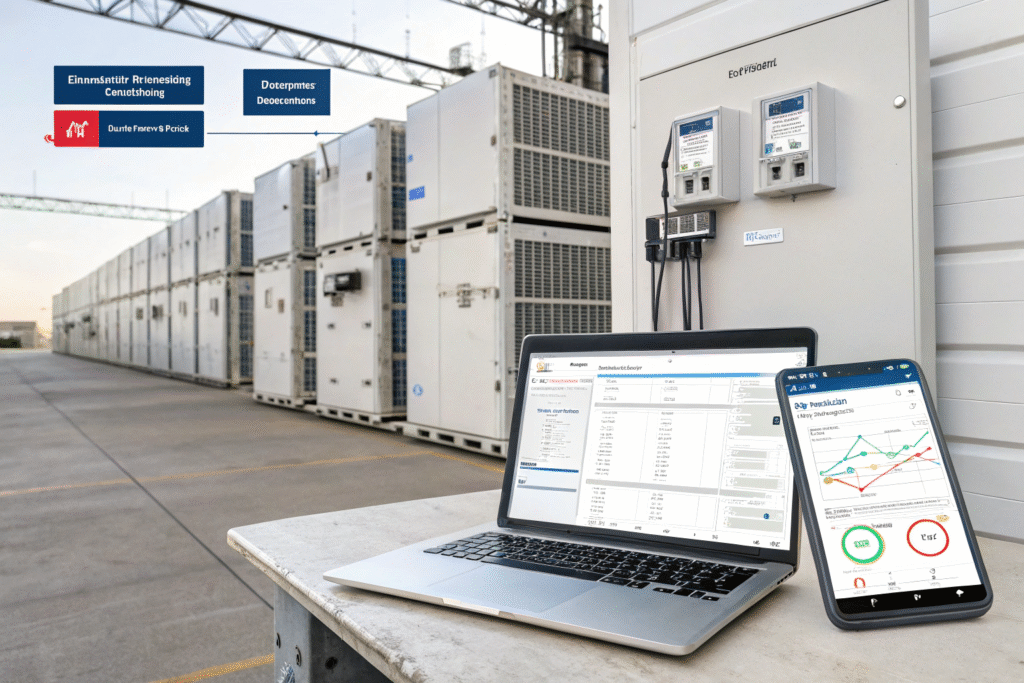

What Monitoring Technologies Provide the Best Visibility?

Wireless data loggers record temperature throughout transit. Modern loggers provide continuous monitoring with 0.1°C accuracy, storing data for download upon arrival and often transmitting alerts during excursions.

Remote monitoring systems enable real-time intervention. Satellite or cellular-connected monitors transmit temperature data during transit, allowing proactive response to equipment issues before product damage occurs.

Multiple sensor placements capture spatial variations. Placing monitors in different container locations (door, center, top, bottom) identifies temperature variations that single-point monitoring might miss.

What Documentation Creates a Defensible Cold Chain?

Temperature logs from origin to destination provide complete chain of custody. Documentation should begin at manufacturing, continue through transportation, and extend to final storage facility.

Equipment performance records verify proper operation. Carrier maintenance records, pre-trip inspections, and performance certifications demonstrate equipment reliability and proper handling.

Standard operating procedures (SOPs) document handling protocols. Written procedures for loading, monitoring, and emergency response create consistency and demonstrate due diligence.

How Do You Manage Customs for Refrigerated Goods?

Customs clearance requires special considerations for temperature-controlled shipments where delays can destroy product value.

What Special Documentation Supports Refrigerated Imports?

Import permits for temperature-controlled products often have additional requirements. FDA prior notice for foods, USDA permits for agricultural products, and specific pharmaceutical import licenses may require temperature control verification.

Temperature control declarations inform customs of special handling needs. Explicit documentation that shipments require continuous refrigeration helps customs prioritize inspection scheduling to minimize temperature exposure.

Product specifications and stability data support special handling requests. Documentation showing temperature sensitivity and excursion limits helps justify expedited processing for critical shipments.

How Can You Prevent Customs-Related Temperature Excursions?

Advanced submission of documentation expedites clearance. Complete, accurate documentation submitted before arrival reduces examination likelihood and speeds release for temperature-sensitive goods.

Designated examination facilities with temperature control ensure proper handling. When inspections are necessary, using facilities with refrigerated examination areas prevents damage during customs processing.

Contingency power arrangements protect against extended delays. Having backup generators or temporary refrigeration available at ports prevents spoilage during extended customs holds or equipment failures.

What Are the Cost Optimization Strategies?

While refrigerated shipping costs more than dry shipping, strategic approaches can optimize expenses without compromising temperature integrity.

How Can You Reduce Refrigerated Shipping Costs?

Consolidation with compatible products maximizes equipment utilization. Shipping smaller quantities with other temperature-compatible products spreads fixed costs across multiple shippers.

Equipment selection based on actual needs prevents over-specification. Using standard reefers instead of super-freezers when temperature requirements allow can reduce costs 15-25%.

Routing optimization balances transit time and cost. Sometimes slightly longer routes with better equipment availability or lower costs provide better overall value despite extended transit times.

What Operational Efficiencies Lower Expenses?

Loading and unloading efficiency reduces energy consumption. Faster turnaround times minimize refrigeration run time during stationary periods, reducing power consumption and costs.

Preventive maintenance prevents costly emergencies. Regular equipment servicing reduces failure risk that could lead to product loss and emergency transportation expenses.

Seasonal scheduling avoids peak pricing. Shipping during non-peak seasons typically provides better equipment availability and lower rates for refrigerated services.

What Contingency Planning Prevents Catastrophic Loss?

Even with perfect planning, refrigerated shipments face risks that require robust contingency plans to protect valuable temperature-sensitive cargo.

What Equipment Failure Responses Protect Shipments?

Backup power arrangements at transshipment points prevent spoilage during transfers. Identifying facilities with generator backup or portable refrigeration units provides safety nets during equipment failures.

Redundant monitoring ensures failure detection. Multiple independent monitoring systems provide backup if primary systems fail, ensuring temperature excursions are detected promptly.

Alternative equipment sourcing plans enable quick recovery. Relationships with multiple equipment providers allow rapid replacement of malfunctioning reefers or containers.

How Should You Handle Temperature Excursions?

Immediate assessment protocols determine product impact. Established procedures for evaluating excursion severity and product impact enable rapid decision-making about disposition.

Salvage options identification minimizes total loss. Understanding reprocessing, remarketing, or alternative use options for partially affected products can recover some value from compromised shipments.

Insurance claim procedures documentation facilitates recovery. Detailed procedures for documenting incidents and filing claims ensure maximum recovery when losses occur.

Conclusion

Shipping refrigerated goods from China successfully requires treating temperature control as an integrated system rather than just a transportation feature. The most reliable approaches combine appropriate transportation mode selection, robust packaging, continuous monitoring, and comprehensive contingency planning.

At GeeseCargo, we've developed refrigerated shipping protocols that achieve 99.4% temperature compliance for our clients, transforming what many consider high-risk shipments into predictable, reliable operations. The key lies in understanding that refrigerated shipping success depends on controlling the entire cold chain, not just selecting equipment.

Begin your refrigerated shipping planning by thoroughly understanding your product's temperature requirements and stability limits, then design a complete cold chain solution that addresses each potential vulnerability. Remember that in refrigerated shipping, the cost of prevention is always lower than the cost of failure—both financially and in terms of customer trust and product integrity.