Last quarter, one of our clients faced a 45-day delay at Los Angeles port that nearly collapsed their seasonal business. As the founder of GeeseCargo, I've witnessed how port congestion can devastate supply chains. The good news? Strategic planning can significantly mitigate these risks.

Businesses can avoid port congestion impacts through diversified routing, advanced planning, flexible shipping modes, and technology integration. Successful companies build resilient supply chains that anticipate delays rather than react to them.

Port congestion has become the new normal in global trade. With proper strategies, your business can maintain reliable operations despite port challenges. Let's explore practical approaches that actually work.

What Shipping Strategies Reduce Port Congestion Risks?

Proactive shipping strategies form your first line of defense against port delays. The goal isn't just to ship goods, but to ensure they keep moving regardless of port conditions.

How Can Diversified Routing Save Your Supply Chain?

Relying on a single port creates vulnerability points in your supply chain. Major US ports like Los Angeles and Long Beach frequently experience severe congestion. Adding alternate ports spreads your risk across multiple entry points.

East Coast ports like Savannah and Charleston often have better throughput during West Coast disruptions. Consider Canadian and Mexican ports as additional alternatives for US-bound cargo. Each port has different peak seasons and congestion patterns that you can leverage.

The best routing strategy combines geographical diversity with timing adjustments. Ship earlier than needed and use multiple ports simultaneously. This approach ensures at least some inventory arrives on schedule despite individual port delays.

Why Does Shipping Mode Flexibility Matter?

Combining ocean freight with air and rail options creates crucial flexibility. While ocean shipping remains most cost-effective for large shipments, strategic air freight can bridge critical inventory gaps.

Air-sea combinations work particularly well for time-sensitive components. Ship bulk inventory via ocean while maintaining buffer stock via air. During peak congestion periods, consider rail transport from alternative ports to final destinations.

Multi-modal logistics requires advanced planning but pays dividends during disruptions. The key is maintaining relationships with multiple transport providers across different modes.

How Can Technology Help Navigate Port Challenges?

Modern technology provides unprecedented visibility and control over shipping processes. Digital tools transform how businesses anticipate and respond to port congestion.

What Visibility Tools Provide Early Warning?

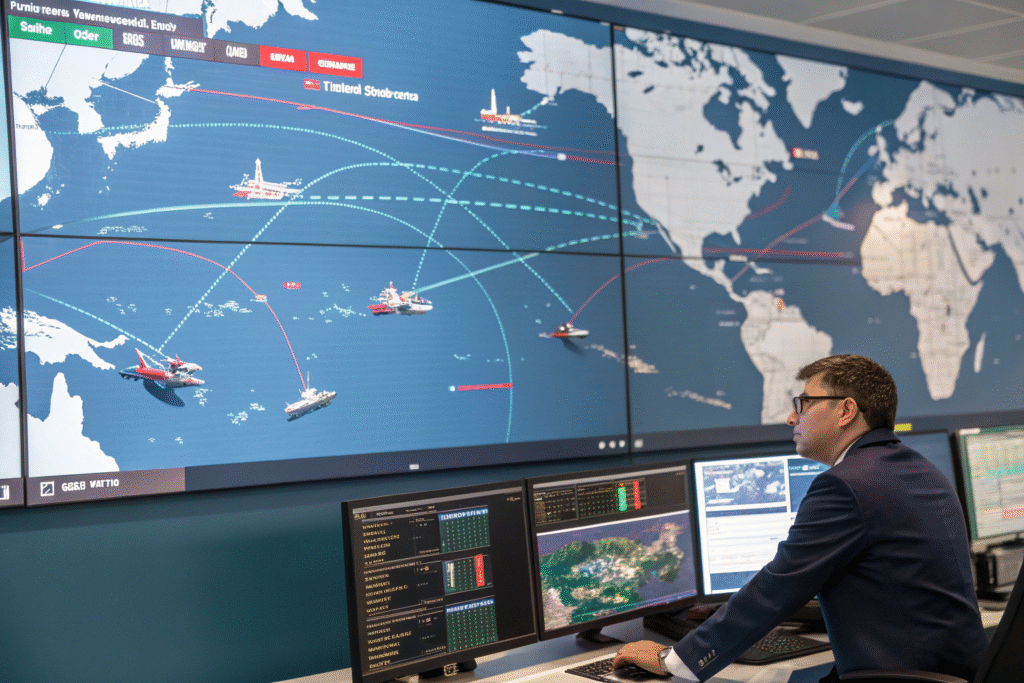

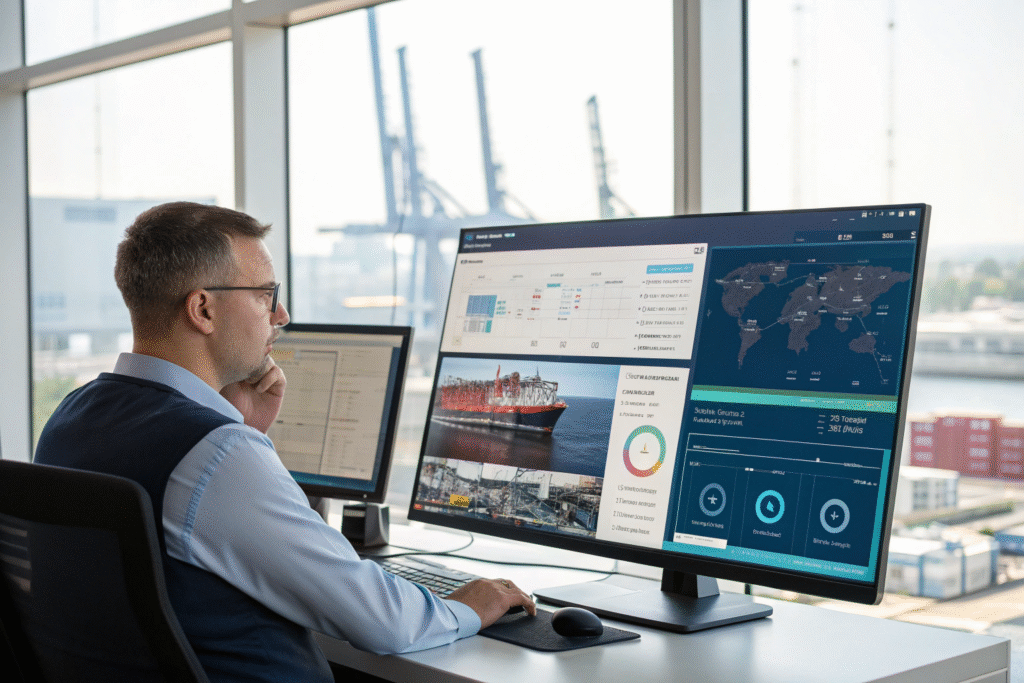

Real-time tracking systems have evolved beyond simple vessel locations. Modern platforms like our GeeseCargo dashboard integrate multiple data sources to predict congestion before it impacts your shipments.

Port capacity analytics help anticipate delays weeks in advance. Weather pattern integration predicts natural disruption events. Social-political monitoring flags potential labor actions that could slow port operations.

The most effective systems combine historical data with real-time inputs. They don't just show current conditions but predict future bottlenecks. This predictive capability allows for proactive rerouting before congestion occurs.

How Does Automation Improve Congestion Response?

Automated documentation processing significantly reduces port clearance times. Manual paperwork errors cause substantial delays at congested ports where officials have limited patience for discrepancies.

Electronic data interchange systems ensure accurate, timely submission of customs documents. Automated booking systems can quickly secure alternative transport when congestion strikes. Smart contracts can automatically trigger alternative routing when specific congestion thresholds are met.

The speed of automated systems becomes crucial during port crises. While humans analyze the big picture, automation handles the time-sensitive details that keep goods moving.

What Operational Changes Minimize Congestion Impact?

Internal process adjustments can dramatically reduce your vulnerability to external port conditions. Sometimes the most effective solutions involve changing how you operate rather than how you ship.

How Does Inventory Strategy Affect Port Vulnerability?

Traditional just-in-time inventory models collapse under port congestion pressure. Maintaining strategic buffer stock provides crucial breathing room when shipments delay. The key is calculating optimal buffer levels that balance cost with protection.

Seasonal demand patterns should inform your inventory strategy. Build larger buffers before peak seasons and major shopping events. Consider positioning inventory in multiple regional warehouses rather than single central locations.

Smart inventory management means different strategies for different product categories. High-turnover items need larger buffers than slow-moving products. ABC analysis helps prioritize where to invest in protective inventory.

Why Does Supplier Coordination Matter?

Isolated planning guarantees supply chain failures during congestion periods. Regular communication with suppliers ensures everyone operates with the same information and expectations.

Shared visibility platforms allow suppliers to monitor shipment progress alongside you. Collaborative planning helps suppliers adjust production schedules based on transport conditions. Consolidated shipments from multiple suppliers reduce overall container movements and complexity.

The strongest supply chains function as integrated ecosystems rather than sequential handoffs. When all partners share visibility and goals, they can collectively navigate around congestion obstacles.

How Can Partnership Strategies Build Resilience?

The right logistics partnerships transform how your business handles port challenges. Some solutions simply can't be implemented alone in today's complex global trade environment.

What Makes a Logistics Partner Effective During Crises?

Experience matters tremendously during port congestion events. Partners who've navigated multiple crises bring invaluable knowledge about what actually works versus theoretical solutions.

Network depth distinguishes adequate partners from exceptional ones. Providers with strong relationships across multiple ports, carriers, and terminals can secure capacity when others cannot. Financial stability ensures they can handle the cash flow challenges that congestion creates.

The best partners offer proactive advice rather than reactive responses. They should alert you to developing congestion issues before you notice them yourself. True partnership means they're invested in preventing your problems, not just solving them.

How Can Collaborative Relationships Create Advantages?

Transactional shipping relationships collapse when capacity tightens during congestion periods. Long-term partnerships ensure priority treatment when everyone struggles to find space.

Shared risk-reward arrangements align interests during challenging periods. Transparent cost structures build trust that pays dividends during crises. Regular strategic reviews identify improvement opportunities before problems emerge.

The most resilient supply chains feature deeply integrated manufacturer-forwarder relationships. These partnerships develop institutional knowledge that can't be replicated through spot market transactions.

Conclusion

Port congestion represents a persistent challenge rather than a temporary inconvenience. The businesses that thrive despite these conditions build resilience into their supply chain DNA. They diversify routes, leverage technology, adjust operations, and cultivate strong partnerships.

At GeeseCargo, we've helped hundreds of clients transform their approach to port challenges. The most successful implementations combine multiple strategies rather than relying on single solutions. Remember that congestion avoidance isn't about finding one magic bullet—it's about building a comprehensive system that anticipates and adapts to constantly changing conditions.

Start with one strategy from each category discussed above. Measure improvements, then expand your approach. Within a few shipping cycles, you'll have a supply chain that survives—and even thrives—despite port congestion.