Peak season ocean freight is a battlefield. Between July and October, and again before Chinese New Year, ocean carriers face demand surges that strain capacity, raise prices, and test even the most seasoned importers. For buyers like Ron—moving large volumes from China to the U.S.—a misstep during peak season can mean lost sales and rising costs.

Freight forwarders help clients navigate peak seasons through early booking, smart routing, demand forecasting, container strategy, and carrier negotiations.

At GeeseCargo, we manage peak periods every year and help importers keep cargo flowing on schedule, despite limited space and volatile pricing. Here’s how to stay ahead.

When Is Peak Season and Why Is It So Challenging?

Peak season isn’t just one month—it’s a global tidal wave of demand. Retailers, wholesalers, and e-commerce brands all rush to ship before critical deadlines.

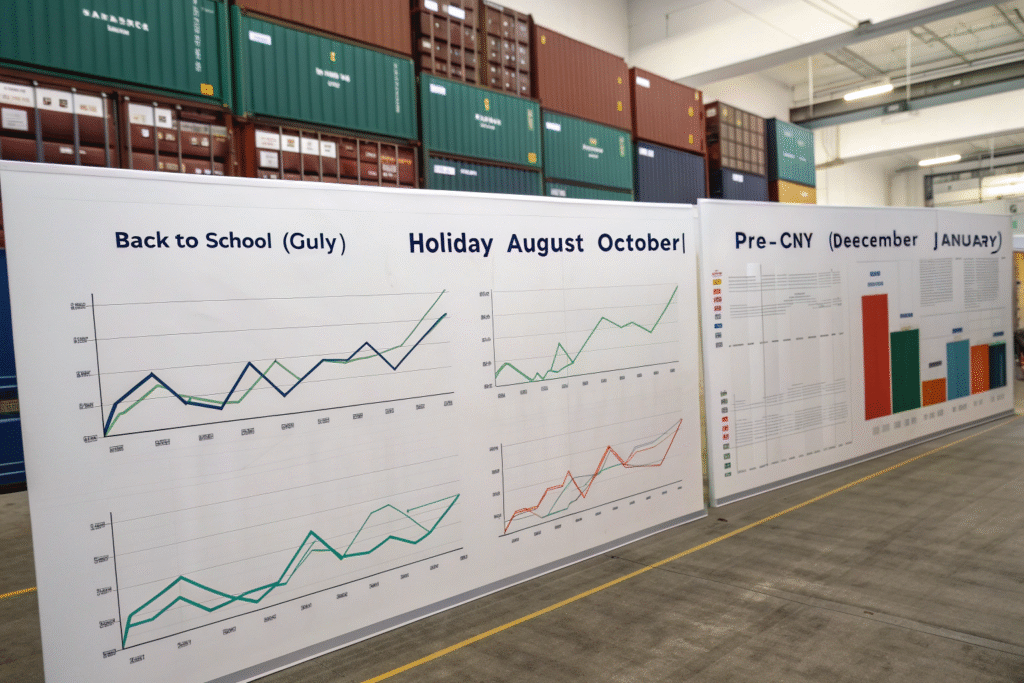

Ocean freight peak seasons occur during July–October and January–February, driven by major shopping cycles and factory shutdowns.

What Triggers Peak Season in Ocean Freight?

Peak season aligns with inventory build-up for Back-to-School, Black Friday, Christmas, and Lunar New Year. Carriers implement General Rate Increases (GRIs) to raise prices as space becomes limited.

Ports like Shanghai, Ningbo, and Yantian face congestion, and equipment (especially containers) becomes scarce.

Why Is Capacity So Unpredictable?

Shipping alliances like 2M, Ocean Alliance, and THE Alliance adjust sailings based on vessel availability and demand. Sometimes they cancel routes—called blank sailings—leaving cargo stranded.

We track these changes in real-time to protect our clients’ bookings.

How Can Importers Prepare Before the Rush Starts?

Success during peak season starts long before the first container is loaded.

Importers can reduce risks by forecasting demand early, booking space in advance, and aligning purchase orders to vessel schedules.

When Should You Start Booking for Peak Season?

We advise clients to secure space 4–6 weeks in advance of the sailing date during peak season. For example, holiday goods shipping in September should be booked by early August.

Use platforms like Freightos or Maersk Spot to access real-time capacity and pricing.

How Can Forwarders Help with Demand Forecasting?

We coordinate with your procurement team to build a rolling forecast. Tools like NetSuite or Anvyl integrate your purchase orders with our logistics calendar, allowing us to reserve space on key sailings in advance.

This prevents last-minute scrambles and airfreight upgrades.

What Strategies Help You Secure Container Space?

During peak season, space—not just price—is the real battleground.

Forwarders use allocation contracts, flexible routing, and creative container strategies to keep goods moving during high-demand periods.

What’s Better—FCL or LCL During Peak?

Full container load (FCL) is more secure and prioritized by carriers. But if your volume is low, LCL (Less-than-Container Load) might be your only option.

We consolidate shipments from multiple suppliers into one FCL when possible—saving cost and ensuring space. If LCL is needed, we use top-tier consolidators like Shipco and ECU Worldwide.

Can Alternate Ports Improve Your Odds?

Yes. We monitor congestion at ports like Ningbo, Shenzhen, and Qingdao, and shift to faster-moving terminals nearby. For U.S. arrivals, switching from Los Angeles to Houston or Savannah can avoid delays.

We use PortCast and MarineTraffic to make real-time routing decisions.

How Do You Manage Rate Increases and Budget Fluctuations?

Rates during peak season can double in a matter of days. Smart timing and contracts are key.

Forwarders lock in rates early, offer fixed-rate contracts, and split shipments to balance costs and ensure on-time delivery.

What Is a GRI and How Can You Avoid It?

A General Rate Increase (GRI) is a scheduled hike in freight rates during peak season. It can be $500–$1500 per container.

We help clients avoid GRIs by pre-booking, using Named Account Contracts (NACs) with carriers, or by shipping early.

Can You Break Shipments Into Smaller Waves?

Yes. Instead of waiting for all goods to be ready, we recommend partial shipments. For example, Ron’s October launch items can be split into two containers—one shipped in August, one in early September. This spreads risk and reduces warehouse pressure.

We track PO readiness using Trello or ClickUp to coordinate split bookings.

Conclusion

Ocean freight peak seasons are intense—but not impossible. With the right planning, carrier relationships, and route strategy, you can stay ahead of the chaos and keep your supply chain flowing.

At GeeseCargo, we specialize in helping importers like Ron prepare for and thrive during peak months. From early booking to smart container planning and real-time rerouting, we take the stress out of the busiest times of year.

Let us help you make peak season feel like just another smooth delivery.